Manufactur standard Laser Cutting Machine Portable - Large Format Industrial Metal Optical Fiber Laser Cutting Machine – Fortune

Manufactur standard Laser Cutting Machine Portable - Large Format Industrial Metal Optical Fiber Laser Cutting Machine – Fortune

Manufactur standard Laser Cutting Machine Portable - Large Format Industrial Metal Optical Fiber Laser Cutting Machine – Fortune Detail:

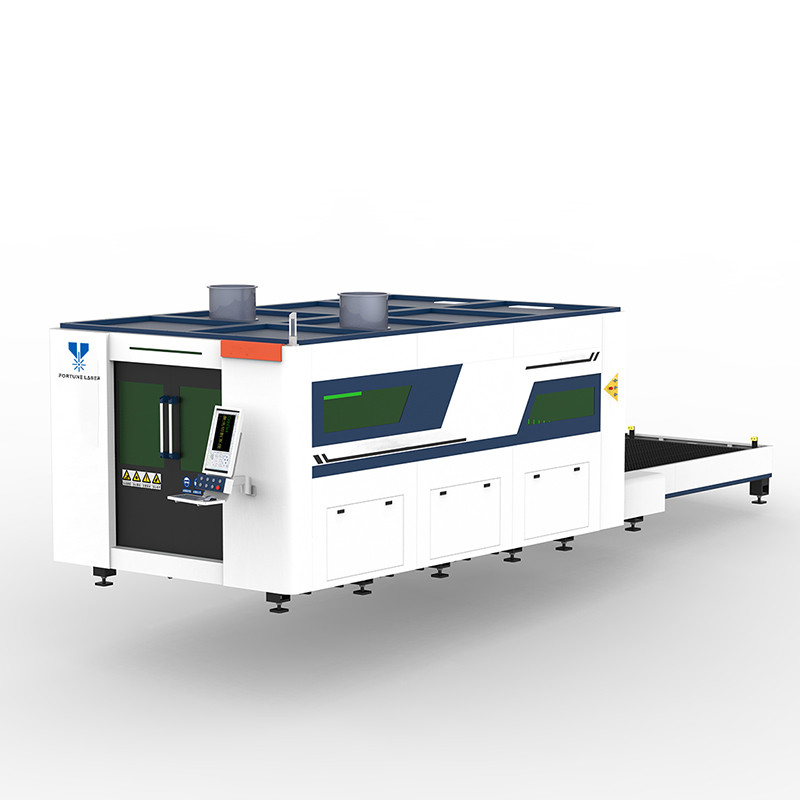

Fortune Laser has expanded the fiber laser cutting system with extra-large format. The extra-large format not only increases the machine’s productivity, because large metal sheets allow the cut parts to be nested more efficiently, but also significantly reduces undesirable raw material offcuts.

The large format also increases the variety of cutting applications. Large-format metal sheets allow large parts to be cut in addition to diverse small parts, without requiring the machine to interrupt the laser cutting process. This provides a competitive advantage that laser cutting systems in the common standard formats cannot offer.

Maximum cutting area could be 16000mm*3000mm or more, depending on your working ,and the laser power up to 20000W.

Product Parameters

|

Machine Model |

FL-L12025 |

FL-L13025 |

FL-L16030 |

|

Working Area(mm) |

12000*2500 |

13000*2500 |

16500*3200 |

|

power of Generator |

3000-20000W |

||

|

X/Y-axis Positioning Accuracy |

0.02mm/m |

||

|

X/Y-axis Repositioning Accuracy |

0.03mm/m |

||

|

X/Y-axis Max. linkage speed |

80m/min |

||

|

Maximum acceleration |

1.2G |

||

|

Power Supply |

Three phase 380V/50Hz 60Hz |

||

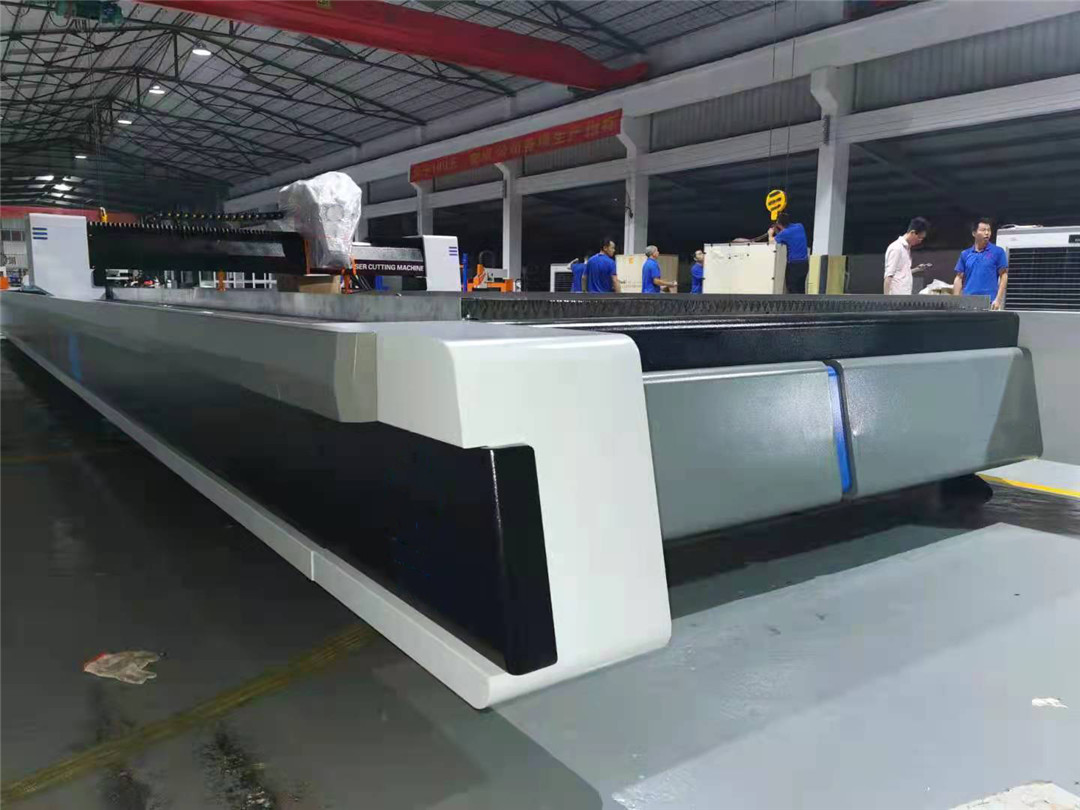

Customize The Processing Format at Will

Fortune Laser provides the flexibility to deal with ultra-large-format thick plates, segmented splicing bed, and the format can be customized on demand.

The separate design of the bed and worktable ensures the high dynamic performance of the machine tool and the service life of the machine tool.

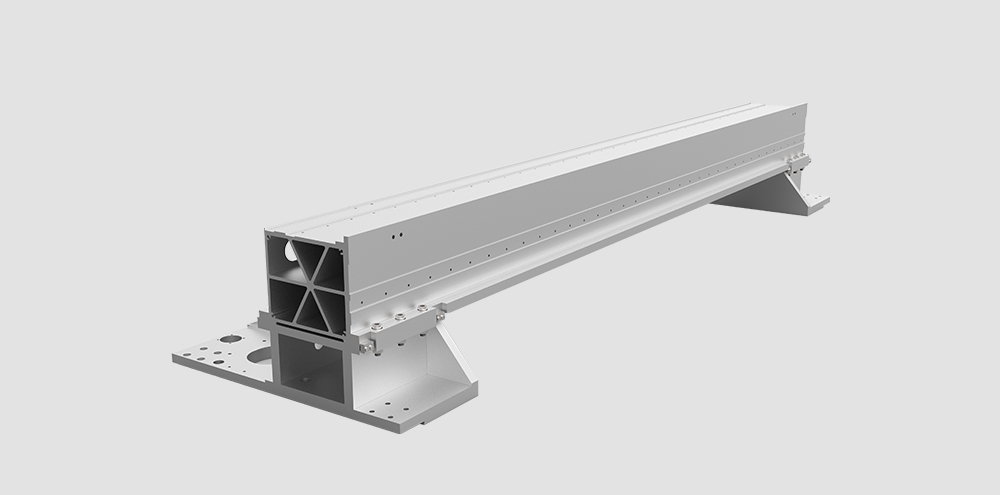

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Precitec Smart Auto Focus Cutting Head

● Motorized focus position adjustment for automatic machine setup and piercing work

● Lightweight and slim design created for fast acceleration and cutting speed

● Drift-free, fast-reacting distance measurement

● Permanent protective window monitoring

● Completely dust-proof beam path with protective windows

● LED operating status display

● Pressure monitoring in the nozzle area (gas cutting) and in the head

Fiber Laser Source

● World Famous Brand. Powerful cutting ability with stainless steel, aluminum and other metal materials, cutting thickness is up to 40mm.

● Long Service Life. The laser has stable performance, the service life can reach 100000 hours, and the overall quality of the equipment can be guaranteed safely.

Stable Cutting Performance

Fiber laser source can produce excellent beam quality, finer cutting lines, higher working efficiency and better machining quality. Fully closed constant temperature working environment makes laser source more effective to ensure the stable operation.

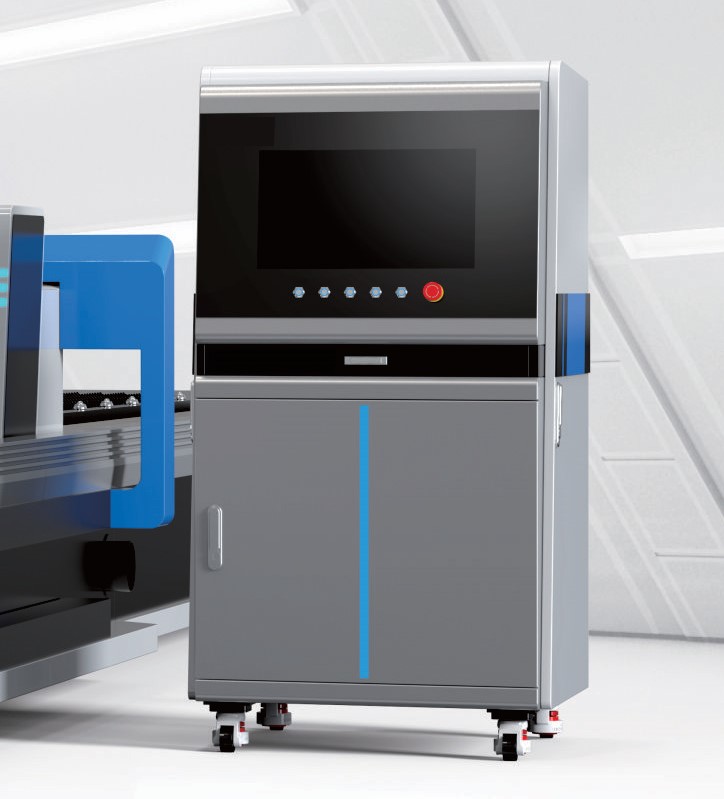

Independent Control Cabinet

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolong the lifespan of the electrical components.

Product detail pictures:

Related Product Guide:

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for Manufactur standard Laser Cutting Machine Portable - Large Format Industrial Metal Optical Fiber Laser Cutting Machine – Fortune , The product will supply to all over the world, such as: Ghana, Czech Republic, Detroit, Now the competition in this field is very fierce; but we will still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. "Change for the better!" is our slogan, which means "A better world is before us, so let's enjoy it!" Change for the better! Are you ready?

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.