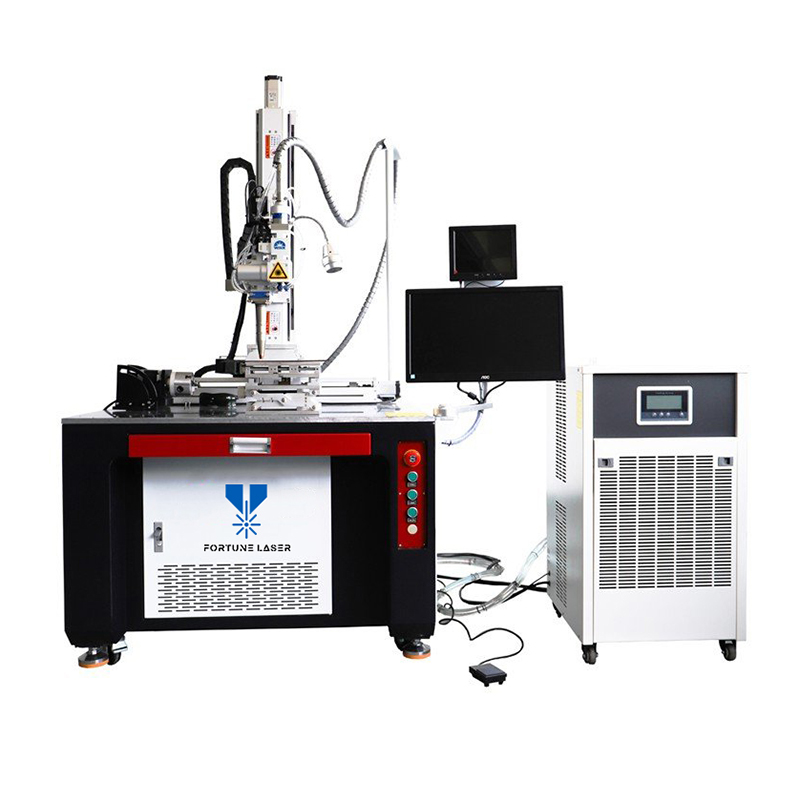

Leading Manufacturer for Small Fibre Laser Cutting Machine - Economical Metal Fiber Laser Cutting Machine – Fortune

Leading Manufacturer for Small Fibre Laser Cutting Machine - Economical Metal Fiber Laser Cutting Machine – Fortune

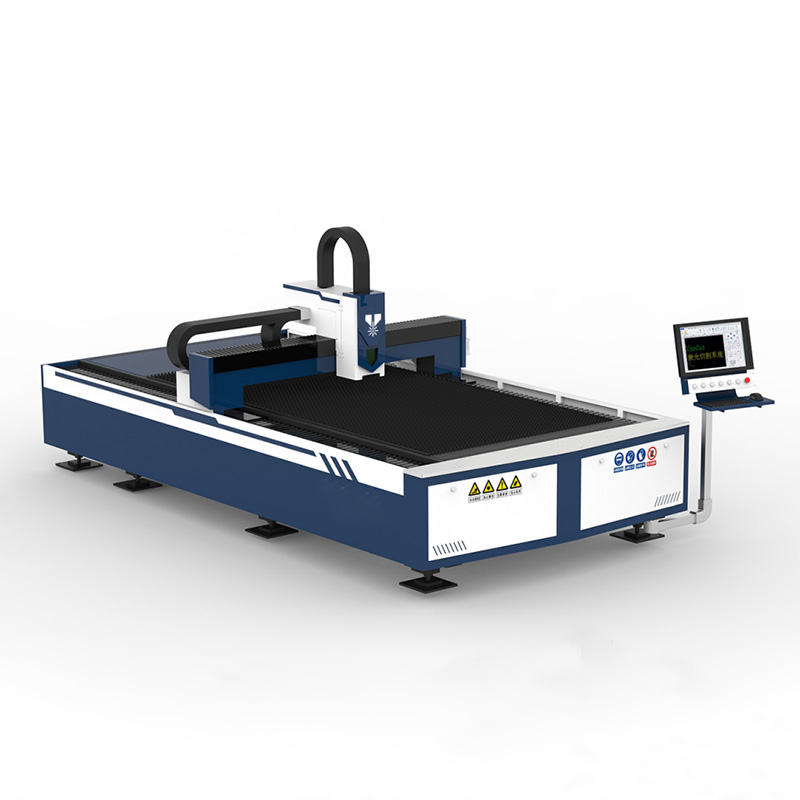

Leading Manufacturer for Small Fibre Laser Cutting Machine - Economical Metal Fiber Laser Cutting Machine – Fortune Detail:

Metal Laser Cutting Machine Characters

● Servo dual drive gantry structure: Bridge gantry structure laser machine, rack rail drive, use centralized lubrication device, and it’s easy for maintenance;

● Practical and Stable : Reinforced welding machine bed, high temperature tempering treatment vibration to eliminate the stress. The machine tool deformation can be controlled at ± 0.02mm;

● The operation is simple: More than 23000 users use this professional CNC cutting system. This operation system has the function of laser power adjustment to ensure the quality of cutting;

● Industrial aesthetics design: Export standards in Europe and America, the appearance of aesthetic design makes it welcomed in global market;

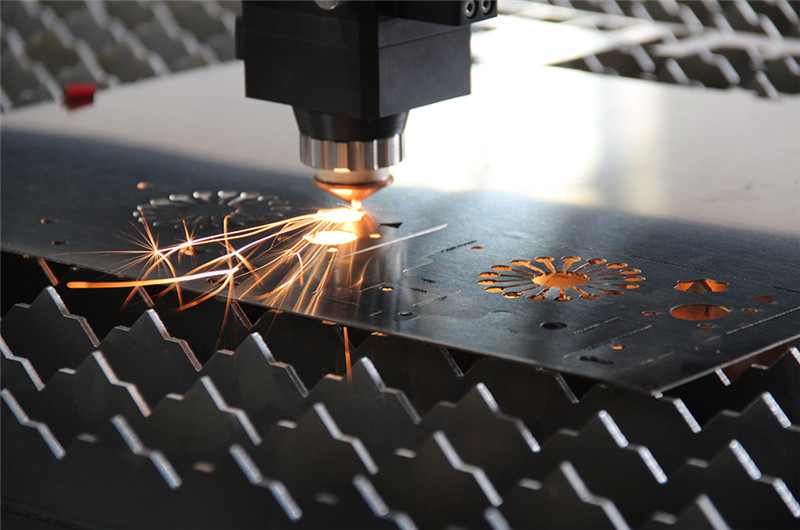

● High-quality cutting: The High-precision anti-collision professional laser cutting head ensures the best cutting effect for your work pieces and projects;

● Efficient material: Used in the standard specifications of metal sheet cutting, save time and cost;

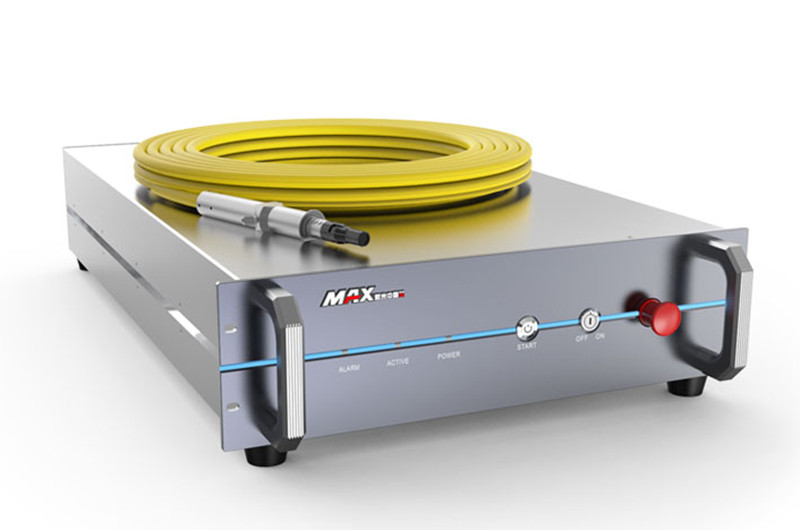

● Fiber laser: Use Maxphotonics fiber laser source(Other brands laser are optional), stable and reliable power, performance guaranteed;

|

Machine configuration |

|

| Model | Fiber Laser Cutting Machine FL-S Series |

| Working Area | 3000mm*1500mm |

| Laser source | 1000w Max |

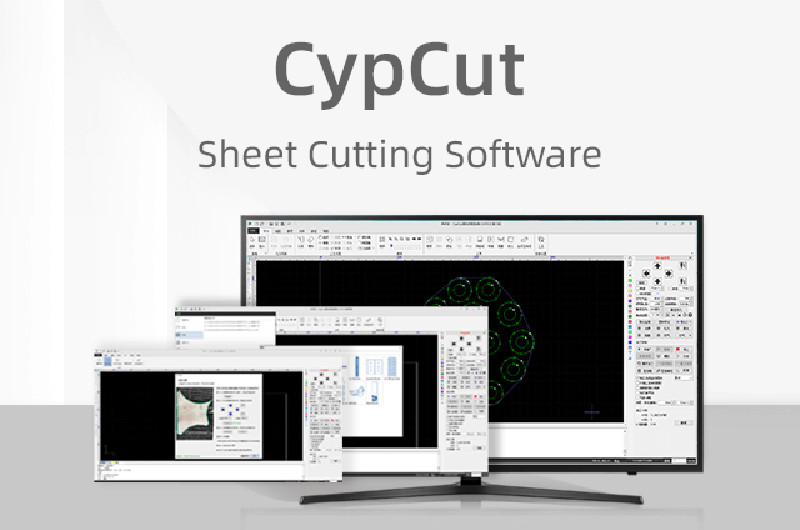

| CNC Cutting System | Cypcut 1000 operating system |

| Laser head | OSPRI Manual focus |

| Machine bed | Fortune Laser |

| X/Y axis gear rack | Fortune Laser |

| Precision linear guide | ROUST |

| Motor Drive | Japan Yaskawa Servo motor (X750W/Y750W/Z400W) |

| Electronic components | France Schneider |

| Reducer system | PHILANDE |

| Pneumatic components | Japan SMC |

| Machine bed accessories | Fortune Laser |

| Water chiller | Hanli |

| Waste recycling equipment | Fortune Laser |

Note: This machine configuration is only for your reference, many other brands for each part of the machines are optional based on your requirements and your budget. Please feel free to contact us for more details.

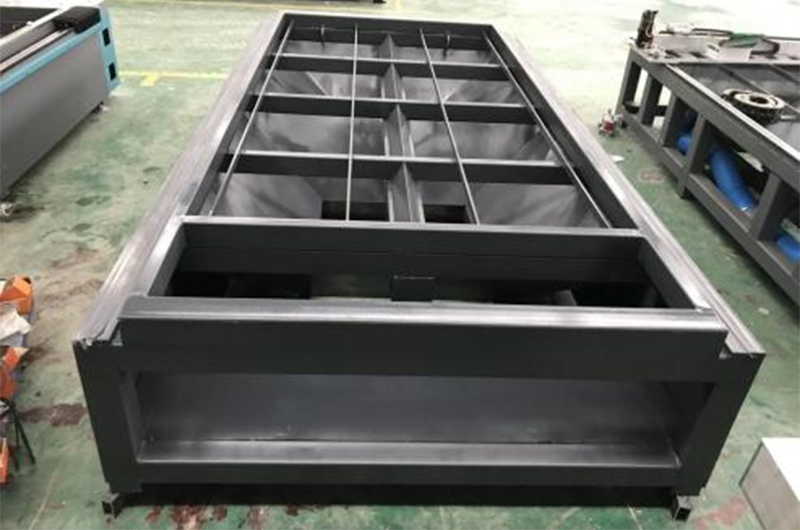

Strong Machine Lathed Bed

The lathed bed is after aging treatment of 1600℃high temperature heat treatment, 24 hours with furnace cooling and precise co2 protection welding, which ensures a long-term stability and no deformation.

Aerospace-grade Aluminum Beam

Aerospace grade aluminum are with high speed, good dynamic response, and fast acceleration.

Beam as a whole by the finite element analysis optimization of high rigidity, lightweight design, and durable.

OSPRI Laser Cutting Head

(1). OSPRI laser head is famous brand in China.

(2). Laser cutting head with high precision fiber laser dedicated anti-collision cutting head to ensure high cutting accuracy and cutting efficiency.

Cypcut CNC Control System

Cypcut controller, a fiber laser cutting machine control system, is designed for sheet metal processing industry launched a full-featured open loop control system.

It’s easy to install and adjust, with excellent performance and complete solutions.

MAX 1000W Fiber Laser Source

More stable and cost-efficient for the laser machines, with 100,000 hours life time. Free maintenance.

Cooling Laser Device, Hanli Water Chiller

Protect the fiber laser device in normal temperature, and avoid moisture condensation.

Cooling laser head:

When machine working, laser head will produce large heat, water chiller cooling laser head to make sure the lens and mirrors avoid breaking because of the heat.

Yaskawa Servo Motors and Drivers

The Yaskawa AC servo motors and drivers can improve machine transmission performance.

Machine Parameters

|

Model |

FL-S2015 |

FL-S3015 |

FL-S4020 |

FL-S6020 |

|

Working Area (L*W) |

2000*1500mm |

3000*1500mm |

4000*2000mm |

6000*2000mm |

|

X/Y Axis Position Accuracy |

±0.03mm/1000mm |

±0.03mm/1000mm |

±0.03mm/1000mm |

±0.03mm/1000mm |

|

X/Y Axis Repeat Position Accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

|

Max Moving Speed |

80000mm/min |

80000mm/min |

80000mm/min |

80000mm/min |

|

Max Acceleration |

1.2g |

1.2g |

1.2g |

1.2g |

|

Max Loading Weight |

600kg |

800kg |

1200kg |

1500kg |

|

Power Supply |

AC380V/50Hz |

AC380V/50Hz |

AC380V/50Hz |

AC380V/50Hz |

|

Laser Source Power(Optional) |

1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW/8kW/10kW/12kW/15kW/20kW |

|||

Applications

Suitable for processing metal sheet such as stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel plate, nickel-titanium alloy, inconel, titanium alloy, etc.

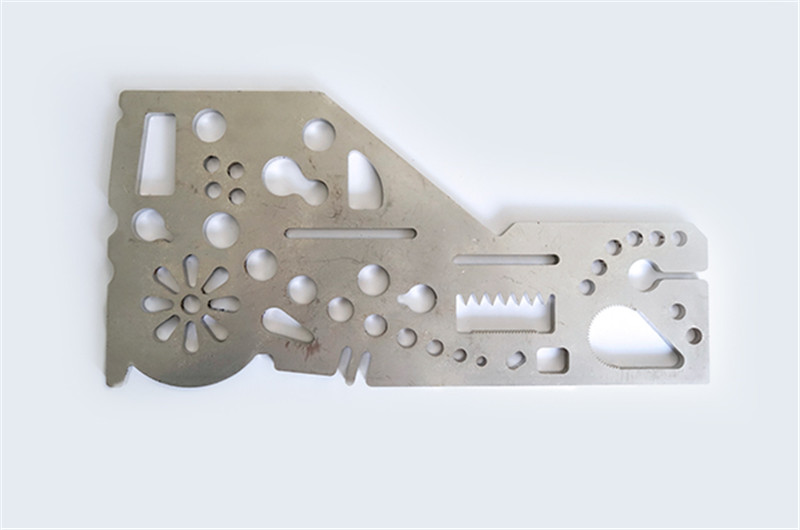

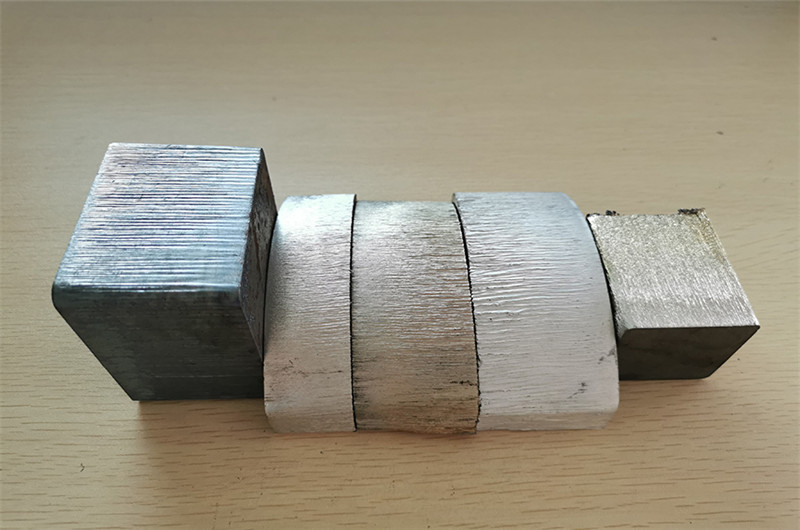

Samples Display

Max Laser Source Cutting Process Parameters

| Note 1: The core diameter of the 1000W~1500W laser output fiber in the cutting data is 50 microns; the core diameter of the 2000~4000W output fiber is 100 microns; | |||||||||

| Note 2: This cutting data adopts Raytools cutting head, collimation/focusing lens focal length: 100mm/125mm; | |||||||||

| Note 3: Due to the differences in equipment configuration and cutting process (machine tool, water cooling, environment, cutting nozzle and gas pressure) adopted by different customers, this data is for reference only; | |||||||||

| Material | Thickness (mm) |

Gas Types |

1000W |

1500W |

2000W |

2500W |

3000W |

4000W |

6000W |

| speed(m/min) | speed(m/min) | speed(m/min) | speed(m/min) | speed(m/min) | speed(m/min) | speed(m/min) | |||

| Stainless Steel | 1 | N2 |

20~24 |

28~32 |

38 |

30 |

50 |

42~43 |

70~75 |

| 2 | N2 |

5.4 |

7.5 |

12 |

10 |

13 |

19~20 |

25~30 |

|

| 3 | N2 |

2.2 |

4 |

7 |

6 |

8 |

11~12 |

12~15 |

|

| 4 | N2 |

1.2 |

2 |

4 |

4 |

5 |

6.5~7.5 |

7.5~9 |

|

| 5 | N2 |

1.1 |

2 |

2.5 |

2.5 |

4~5 |

6~7.5 |

||

| 6 | N2 |

0.8 |

1.5 |

1.5 |

1.5 |

2~3 |

5~6.5 |

||

| 8 | N2 |

0.8 |

0.7 |

1 |

1.5~2 |

3.5~4.5 |

|||

| 10 | N2 |

0.5 |

0.5 |

0.8 |

1 |

2.1 |

|||

| 12 | N2 |

0.5 |

0.8 |

1.1 |

|||||

| 14 | N2 |

0.9 |

|||||||

| Material | Thickness (mm) | Gas Types |

1000W |

1500W |

2000W |

2500W |

3000W |

4000W |

6000W |

| speed(m/min) | speed(m/min) | speed(m/min) | speed(m/min) | speed(m/min) | speed(m/min) | speed(m/min) |

| CarbonSteel | 1 | air |

9~12 |

27~30 |

27~30 |

30 |

50 |

43 |

70~75 |

| 2 | air |

6~8 |

8~10 |

10~12 |

12 |

13 |

20 |

25~30 |

|

| 3 | O2 |

3 |

3 |

3 |

4 |

4.5 |

4.5 |

4.5 |

|

| 4 | O2 |

2 |

2.5 |

3.1 |

3.3 |

3.5 |

3.8 |

3.8 |

|

| 5 | O2 |

1.6 |

2 |

2.5~3 |

2.5 |

3 |

3.5 |

3.7 |

|

| 6 | O2 |

1.4 |

1.8 |

2.2 |

2.3 |

2.5 |

2.8 |

3.3 |

|

| 8 | O2 |

1.1 |

1.3 |

1.5 |

1.5 |

2 |

2.3 |

2.8 |

|

| 10 | O2 |

0.9 |

1.1 |

1 |

1.2 |

1.4 |

1.8 |

2.1 |

|

| 12 | O2 |

0.7 |

0.9 |

0.8 |

1 |

1.1 |

1.5 |

1.6 |

|

| 14 | O2 |

0.6 |

0.7 |

0.8 |

0.9 |

1 |

0.95 |

||

| 16 | O2 |

0.5 |

0.6 |

0.7 |

0.8 |

0.9 |

0.85 |

||

| 18 | O2 |

0.5 |

0.6 |

0.7 |

0.8 |

0.75 |

|||

| 20 | O2 |

0.4 |

0.5 |

0.6 |

0.7 |

0.65 |

|||

| 22 | O2 |

0.4 |

0.5 |

0.5 |

0.5 |

||||

| Aluminum | 1 | air |

12~13 |

15 |

17~18 |

29 |

45 |

35~37 |

70~75 |

| 2 | air |

4~4.5 |

6 |

7.5 |

8.5 |

11 |

15 |

25~30 |

|

| 3 | air |

1~1.5 |

3 |

5 |

5 |

7 | 8~9 |

15 |

|

| 4 | air |

0.8~1 |

2 |

3 |

4 |

6 |

10 |

||

| 5 | air |

1 |

1.5 |

3 |

8 |

||||

| 6 | air |

0.6 |

1 |

2 |

5.5 |

||||

| 8 | air | 0.5 |

1 |

2.5 |

|||||

| 10 | air |

0.5 |

1.3 |

||||||

| 12 | air |

0.9 |

|||||||

| Brass | 1 | air |

10 |

12 |

15 |

24 |

40 |

30~33 |

65~70 |

| 2 | air |

3 |

5 |

6 |

7.5 |

10 |

13 |

20~25 |

|

| 3 | air |

0.5 |

2 |

3 |

4 |

4 |

7 |

5 |

|

| 4 | air |

0.5 |

1.5 |

2 |

3 |

5 |

4 |

||

| 5 | air |

0.5 |

1 |

1.5 |

2 |

3 |

|||

| 6 | air |

0.5 |

0.8 |

1.5 |

2 |

||||

| 8 | air |

0.8 |

1.2 |

||||||

| 10 | air |

0.5 |

Working Environment Requirements

1. Humidity requirements are 40%-80%, no condensation.

2. Power grid requirements: 380V; 50Hz/60A.

3. Power supply grid fluctuations: 5%, the grid ground wire meets international requirements.

4. Cutting with auxiliary gas: Clean, dry compressed air and high purity oxygen (O2)and nitrogen(N2), purity no less than 99.9% purity.

5. There should be no strong electromagnetic interference near the installation equipment.

6. Avoid radio transmitters or relay stations around the installation site.

7. Power grounding resistance: ≤ 4 ohms. Ground amplitude: less than 50um; vibration acceleration: less than 0.05g.

8. Avoid a large number of machine tools such as stamping in the vicinity.

9. Air pressure: 86-106kpa.

10. Equipment space requirements are guaranteed to be smoke-free and dust-free, avoiding dusty working environments such as metal polishing and grinding.

11. An anti-static floor must be installed and the shielded cable connected.

12. The water quality of the working cooling circulating water is strictly required, and pure water, deionized water or distilled water must be used.

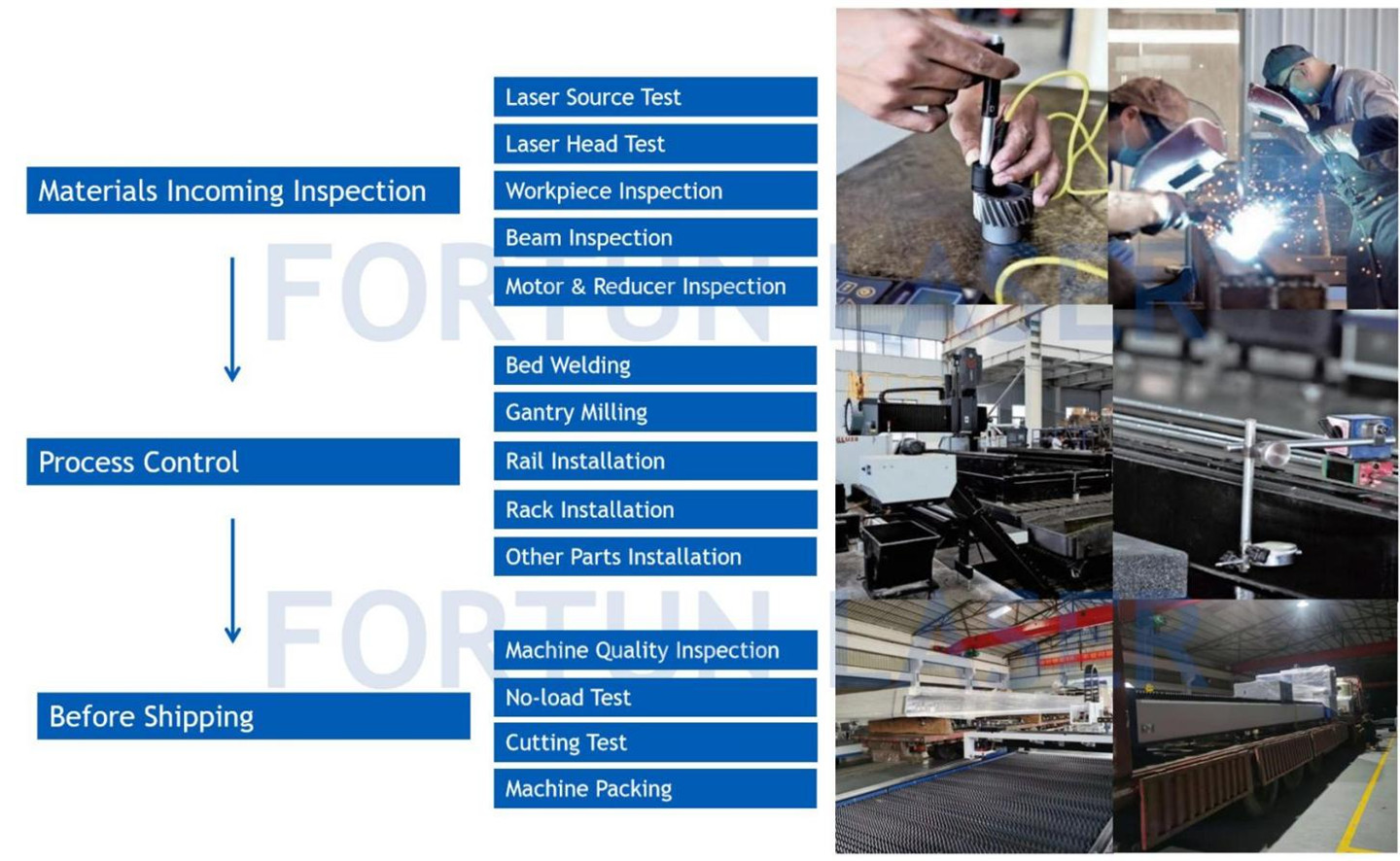

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Leading Manufacturer for Small Fibre Laser Cutting Machine - Economical Metal Fiber Laser Cutting Machine – Fortune , The product will supply to all over the world, such as: Namibia, Jamaica, Lithuania, If any product meed your demand, please feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality products, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!