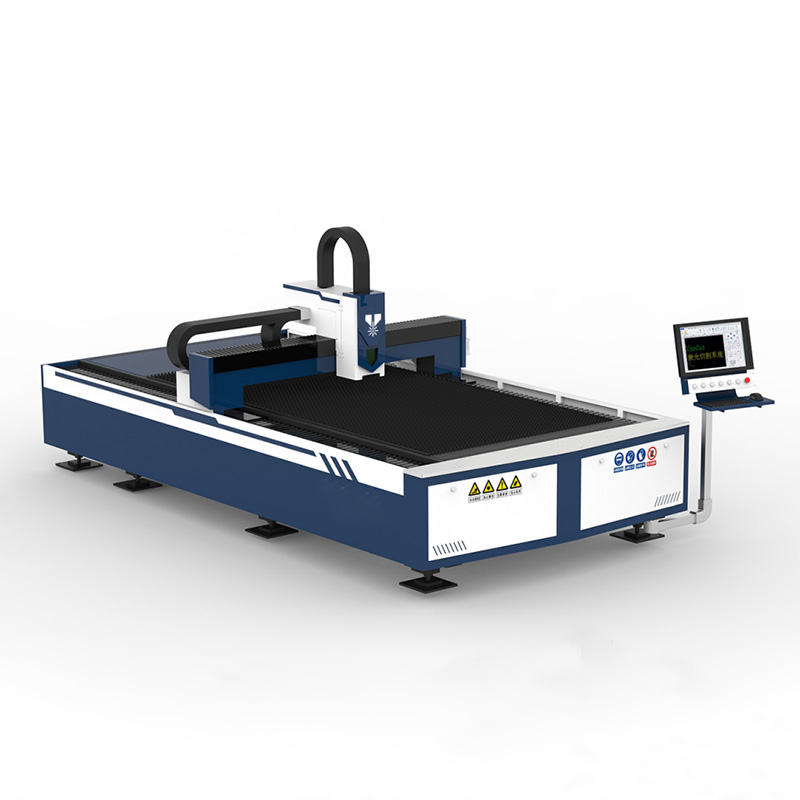

Mesin Cutting Laser Serat Logam Ekonomis

Mesin Cutting Laser Serat Logam Ekonomis

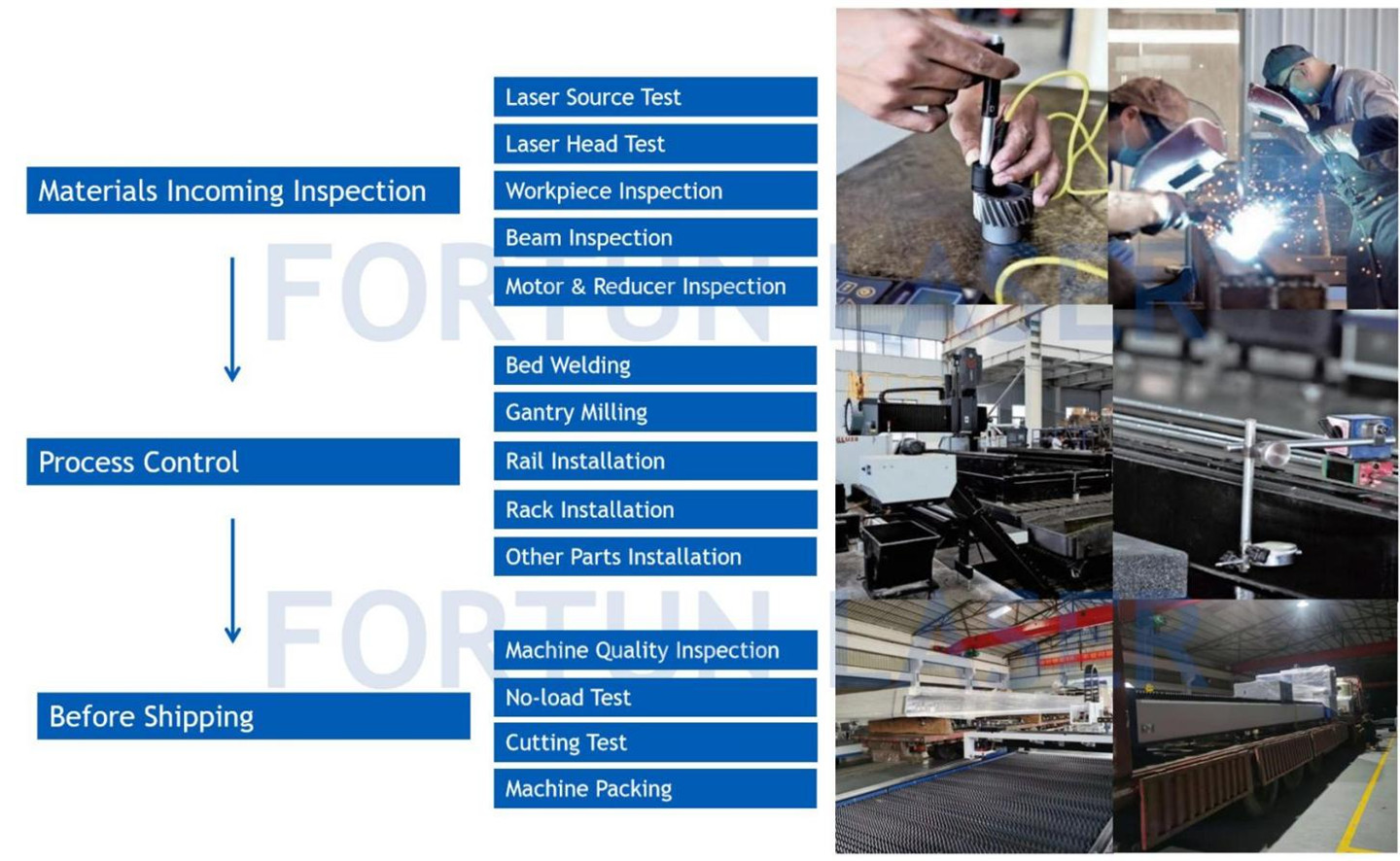

Karakter Mesin Cutting Laser Logam

●Servo dual struktur gantry drive:Mesin laser struktur gantri jembatan, drive rel rak, nggunakake piranti lubrication terpusat, lan gampang kanggo pangopènan;

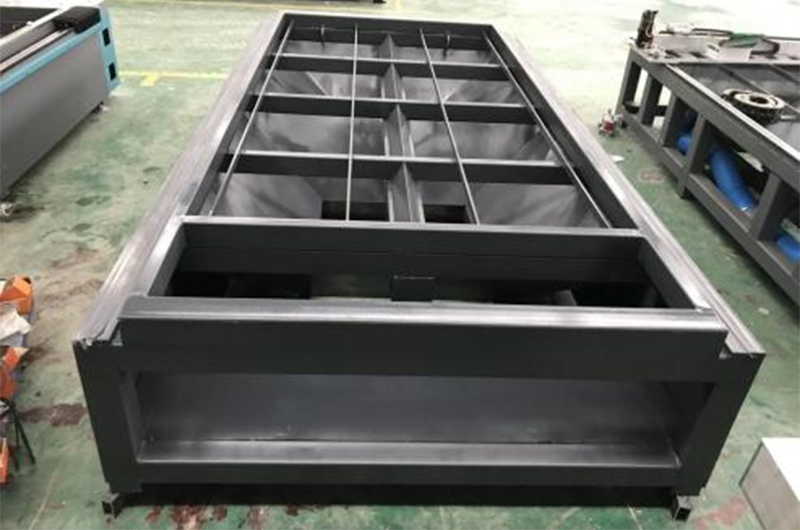

●Prasional lan Stabil: Amben mesin las sing dikuatake, getaran perawatan tempering suhu dhuwur kanggo ngilangi stres. Deformasi alat mesin bisa dikontrol ing ± 0.02mm;

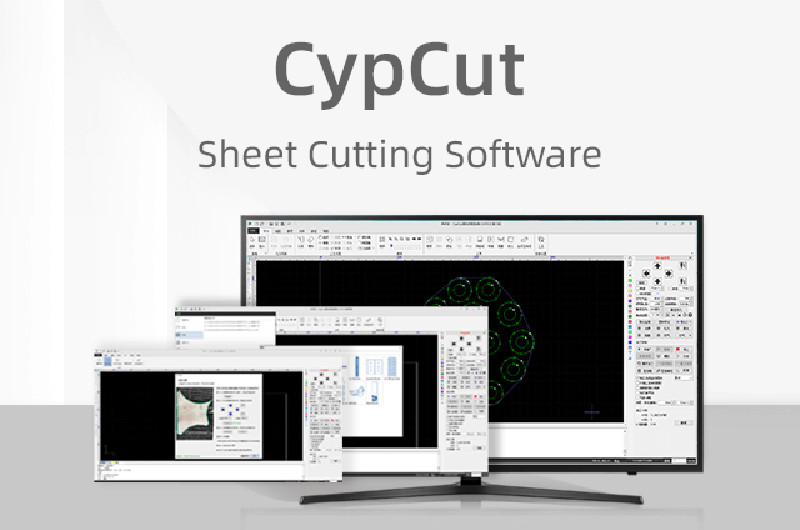

●Operasi iki prasaja: Luwih saka 23000 pangguna nggunakake sistem pemotong CNC profesional iki. Sistem operasi iki nduweni fungsi pangaturan daya laser kanggo njamin kualitas pemotongan;

●Desain estetika industri: Standar ekspor ing Eropa lan Amerika, tampilan desain estetis ndadekake disambut ing pasar global;

●Nglereni kualitas dhuwur:Kepala nglereni laser profesional anti-tabrakan kanthi tliti dhuwur njamin efek pemotongan paling apik kanggo karya lan proyek sampeyan;

●Materi sing efisien:Digunakake ing spesifikasi standar nglereni lembaran logam, ngirit wektu lan biaya;

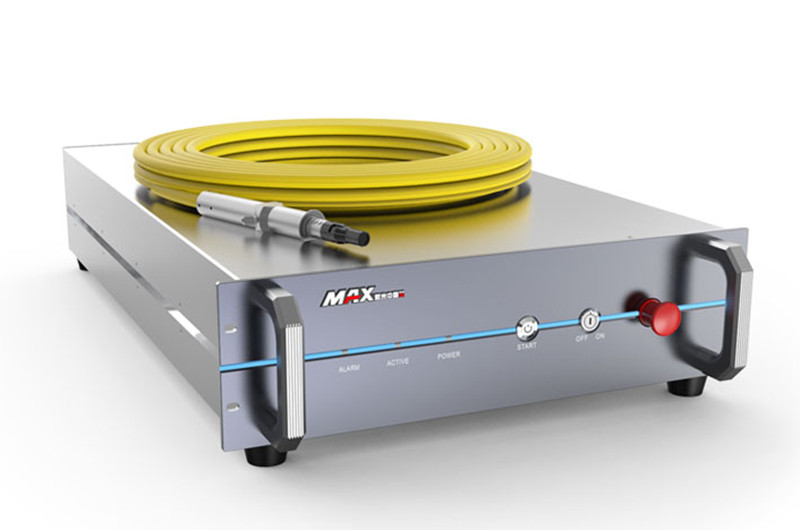

●Serat laser: Gunakake sumber laser serat Maxphotonics (Laser merek liyane opsional), daya stabil lan dipercaya, kinerja dijamin;

| Konfigurasi mesin | |

| Model | Serat Laser Cutting Machine FL-S Series |

| Area Kerja | 3000mm * 1500mm |

| sumber laser | 1000w Maks |

| Sistem Cutting CNC | Sistem operasi Cypcut 1000 |

| sirah laser | Fokus Manual OSPRI |

| Amben mesin | Fortune Laser |

| Rak gear sumbu X/Y | Fortune Laser |

| Panuntun linear presisi | ROOT |

| Penggerak Motor | Motor Servo Yaskawa Jepang (X750W/Y750W/Z400W) |

| komponen elektronik | Prancis Schneider |

| Sistem Reducer | PHILANDE |

| Komponen pneumatik | SMC Jepang |

| Aksesoris amben mesin | Fortune Laser |

| Chiller banyu | Hanli |

| Peralatan daur ulang sampah | Fortune Laser |

Cathetan: Konfigurasi mesin iki mung kanggo referensi sampeyan, akeh merek liyane kanggo saben bagean mesin sing opsional adhedhasar syarat lan anggaran sampeyan. Mangga aran gratis kanggo hubungi kita kanggo rincian liyane.

Parameter mesin

| Model | FL-S2015 | FL-S3015 | FL-S4020 | FL-S6020 |

| Area Kerja (L*W) | 2000 * 1500 mm | 3000 * 1500 mm | 4000 * 2000 mm | 6000 * 2000 mm |

| Akurasi Posisi Sumbu X/Y | ± 0,03mm / 1000mm | ± 0,03mm / 1000mm | ± 0,03mm / 1000mm | ± 0,03mm / 1000mm |

| Akurasi Posisi Baleni Sumbu X/Y | ± 0,02 mm | ± 0,02 mm | ± 0,02 mm | ± 0,02 mm |

| Kacepetan Obah Max | 80000mm / min | 80000mm / min | 80000mm / min | 80000mm / min |

| Akselerasi Max | 1.2g | 1.2g | 1.2g | 1.2g |

| Max Loading Bobot | 600 kg | 800 kg | 1200kg | 1500kg |

| Power Supply | AC380V/50Hz | AC380V/50Hz | AC380V/50Hz | AC380V/50Hz |

| Sumber Daya Laser (Opsional) | 1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW/8kW/10kW/12kW/15kW/20kW | |||

Aplikasi

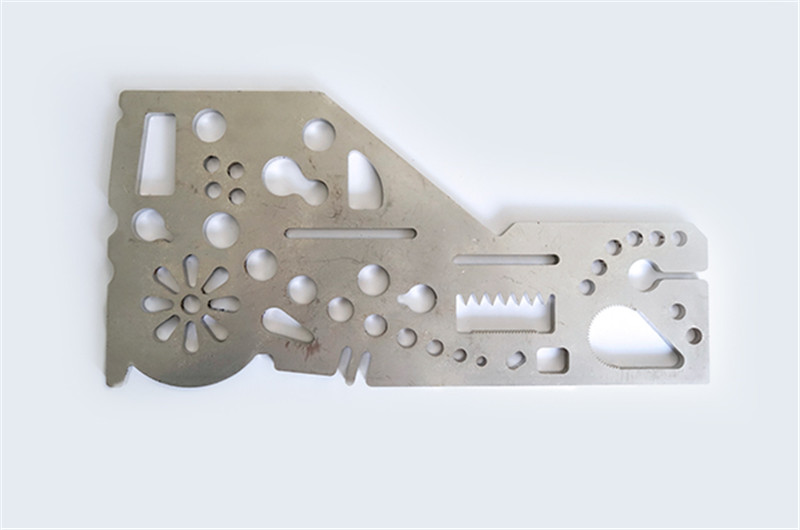

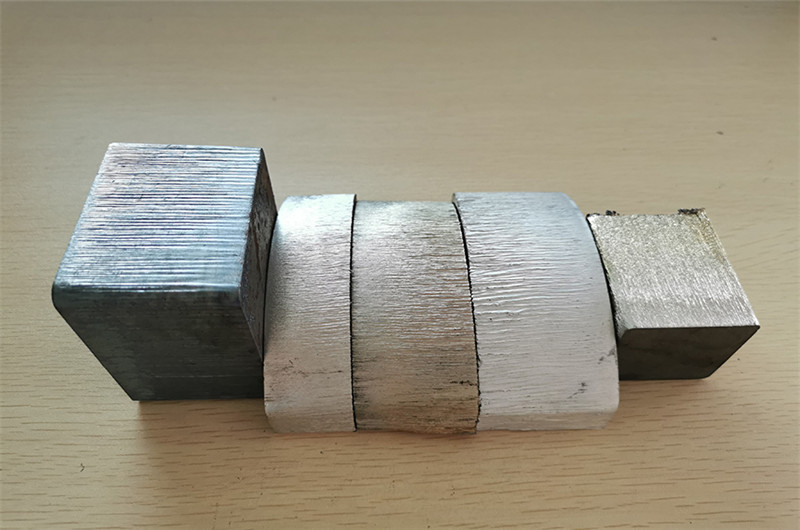

Cocog kanggo ngolah lembaran logam kayata stainless steel, baja karbon, baja paduan, baja silikon, piring baja galvanis, paduan nikel-titanium, inconel, paduan titanium, lsp.

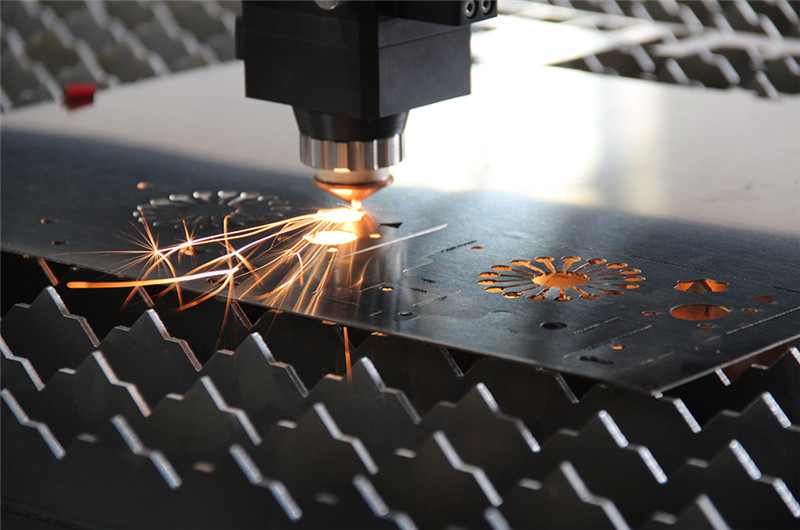

Tampilan Sampel

Parameter Proses Pemotongan Sumber Laser Maks

| Cathetan 1: Dhiameter inti saka serat output laser 1000W ~ 1500W ing data pemotongan yaiku 50 mikron; diameter inti saka 2000 ~ 4000W serat output punika 100 microns; | |||||||||

| Cathetan 2: Data pemotongan iki nganggo kepala pemotong Raytools, collimation / fokus lensa dawa fokus: 100mm / 125mm; | |||||||||

| Cathetan 3: Amarga beda konfigurasi peralatan lan proses pemotongan (alat mesin, pendinginan banyu, lingkungan, nozzle pemotong lan tekanan gas) sing diadopsi dening pelanggan sing beda, data iki mung kanggo referensi; | |||||||||

| Material | Ketebalan (mm) | Gminangka Tipe | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| kacepetan(m / min) | kacepetan(m / min) | kacepetan(m/min) | kacepetan(m / min) | kacepetan(m / min) | kacepetan(m / min) | kacepetan(m / min) | |||

| Baja tahan karat | 1 | N2 | 20~24 | 28~32 | 38 | 30 | 50 | 42~43 | 70~75 |

| 2 | N2 | 5.4 | 7.5 | 12 | 10 | 13 | 19~20 | 25~30 | |

| 3 | N2 | 2.2 | 4 | 7 | 6 | 8 | 11~12 | 12~15 | |

| 4 | N2 | 1.2 | 2 | 4 | 4 | 5 | 6.5~7.5 | 7.5~9 | |

| 5 | N2 |

| 1.1 | 2 | 2.5 | 2.5 | 4~5 | 6~7.5 | |

| 6 | N2 |

| 0.8 | 1.5 | 1.5 | 1.5 | 2~3 | 5~6.5 | |

| 8 | N2 |

|

| 0.8 | 0.7 | 1 | 1.5~2 | 3.5~4.5 | |

| 10 | N2 |

|

| 0.5 | 0.5 | 0.8 | 1 | 2.1 | |

| 12 | N2 |

|

|

|

| 0.5 | 0.8 | 1.1 | |

| 14 | N2 |

|

|

|

|

|

| 0.9 | |

| Material | Ketebalan (mm) | Gminangka Tipe | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| kacepetan(m / min) | kacepetan(m / min) | kacepetan(m/min) | kacepetan(m / min) | kacepetan(m / min) | kacepetan(m / min) | kacepetan(m / min) |

| Baja Karbon | 1 | hawa | 9~12 | 27~30 | 27~30 | 30 | 50 | 43 | 70~75 |

| 2 | hawa | 6~8 | 8~10 | 10~12 | 12 | 13 | 20 | 25~30 | |

| 3 | O2 | 3 | 3 | 3 | 4 | 4.5 | 4.5 | 4.5 | |

| 4 | O2 | 2 | 2.5 | 3.1 | 3.3 | 3.5 | 3.8 | 3.8 | |

| 5 | O2 | 1.6 | 2 | 2.5~3 | 2.5 | 3 | 3.5 | 3.7 | |

| 6 | O2 | 1.4 | 1.8 | 2.2 | 2.3 | 2.5 | 2.8 | 3.3 | |

| 8 | O2 | 1.1 | 1.3 | 1.5 | 1.5 | 2 | 2.3 | 2.8 | |

| 10 | O2 | 0.9 | 1.1 | 1 | 1.2 | 1.4 | 1.8 | 2.1 | |

| 12 | O2 | 0.7 | 0.9 | 0.8 | 1 | 1.1 | 1.5 | 1.6 | |

| 14 | O2 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.95 | ||

| 16 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 0.85 | ||

| 18 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.75 | |||

| 20 | O2 | 0.4 | 0.5 | 0.6 | 0.7 | 0.65 | |||

| 22 | O2 | 0.4 | 0.5 | 0.5 | 0.5 | ||||

| alumunium | 1 | hawa | 12~13 | 15 | 17~18 | 29 | 45 | 35~37 | 70~75 |

| 2 | hawa | 4~4.5 | 6 | 7.5 | 8.5 | 11 | 15 | 25~30 | |

| 3 | hawa | 1~1.5 | 3 | 5 | 5 | 7 | 8~9 | 15 | |

| 4 | hawa | 0.8~1 | 2 | 3 | 4 | 6 | 10 | ||

| 5 | hawa | 1 | 1.5 | 3 | 8 | ||||

| 6 | hawa | 0.6 | 1 | 2 | 5.5 | ||||

| 8 | hawa | 0.5 | 1 | 2.5 | |||||

| 10 | hawa | 0.5 | 1.3 | ||||||

| 12 | hawa | 0.9 | |||||||

| Kuningan | 1 | hawa | 10 | 12 | 15 | 24 | 40 | 30~33 | 65~70 |

| 2 | hawa | 3 | 5 | 6 | 7.5 | 10 | 13 | 20~25 | |

| 3 | hawa | 0.5 | 2 | 3 | 4 | 4 | 7 | 5 | |

| 4 | hawa | 0.5 | 1.5 | 2 | 3 | 5 | 4 | ||

| 5 | hawa | 0.5 | 1 | 1.5 | 2 | 3 | |||

| 6 | hawa | 0.5 | 0.8 | 1.5 | 2 | ||||

| 8 | hawa |

| 0.8 | 1.2 | |||||

| 10 | hawa |

|

| 0.5 |

Persyaratan Lingkungan Kerja

1. Syarat Kelembapan yaiku 40% -80%, ora ana kondensasi.

2. Syarat kothak daya: 380V; 50Hz/60A.

3. Fluktuasi kothak daya: 5%, kabel lemah kothak memenuhi syarat internasional.

4. Cutting karo gas tambahan: resik, online teken garing lan oksigen kemurnian dhuwur (O2) lan nitrogen (N2), kemurnian ora kurang saka 99,9% kemurnian.

5. Aja ana gangguan elektromagnetik sing kuat ing cedhak peralatan instalasi.

6. Ngindhari pemancar radio utawa stasiun relay ing sekitar lokasi instalasi.

7. Daya grounding resistance: ≤ 4 ohm. Amplitudo lemah: kurang saka 50um; percepatan geter: kurang saka 0,05g.

8. Nyingkiri akeh alat mesin kayata stamping ing sacedhake.

9. Tekanan udara: 86-106kpa.

10. Persyaratan papan peralatan dijamin bebas kumelun lan bebas bledug, ngindhari lingkungan kerja sing mbledug kayata polishing lan grinding logam.

11. Lantai anti-statis kudu dipasang lan kabel sing dilindhungi disambungake.

12. Kualitas banyu saka cooling banyu sirkulasi strictly dibutuhake, lan banyu murni, banyu deionized utawa banyu suling kudu digunakake.