Igwe eji agbado ọkụ Laser Handheld Fiber Laser Welding Machine

Igwe eji agbado ọkụ Laser Handheld Fiber Laser Welding Machine

Usoro nka nka na ụzụ Laser Laser Handheld Laser Welder

| Nlereanya | FL-HW1000 | FL-HW1500 | FL-HW2000 |

| Ụdị Laser | 1070nm Fiber Laser | ||

| Ike Laser aha aha | 1000W | 1500W | 2000W |

| Sistemụ jụrụ oyi | Mmiri jụrụ oyi | ||

| Ụzọ ọrụ | Na-aga n'ihu / Modulation | ||

| Ogo nso welder | 0 ~ 120 mm / s | ||

| Dayameta Focal Spot | 0.5mm | ||

| Oke ọnọdụ okpomọkụ | 15-35 ℃ | ||

| Oke iru mmiri gburugburu | <70% enweghị condensation | ||

| Ọkpụrụkpụ ịgbado ọkụ | 0.5-1.5mm | 0.5-2 mm | 0.5-3 mm |

| chọrọ oghere ịgbado ọkụ | ≤1.2mm | ||

| Voltaji na-arụ ọrụ | AC 220V/50HZ 60HZ/380V±5V 50HZ 60HZ 60A | ||

| Akụkụ Cabinet | 120*60*120cm | ||

| Akụkụ ngwugwu osisi | 154*79*137cm | ||

| Ibu | 285KG | ||

| Ogologo eriri | Standard 10M, ogologo ahaziri ogologo bụ 15M | ||

| Ngwa | Welding na ịrụzi igwe anaghị agba nchara, carbon ígwè, aluminum alloy. | ||

Laser Welder Handheld maka Ọla

| Ihe onwunwe | Ike mmepụta (W) | Ntinye kacha (mm) |

| Igwe anaghị agba nchara | 1000 | 0.5-3 |

| Igwe anaghị agba nchara | 1500 | 0.5-4 |

| Igwe anaghị agba nchara | 2000 | 0.5-5 |

| Carbon ígwè | 1000 | 0.5-2.5 |

| Carbon ígwè | 1500 | 0.5-3.5 |

| Carbon ígwè | 2000 | 0.5-4.5 |

| Aluminom alloy | 1000 | 0.5-2.5 |

| Aluminom alloy | 1500 | 0.5-3 |

| Aluminom alloy | 2000 | 0.5-4 |

| Akwụkwọ galvanized | 1000 | 0.5-1.2 |

| Akwụkwọ galvanized | 1500 | 0.5-1.8 |

| Akwụkwọ galvanized | 2000 | 0.5-2.5 |

Agba atọ maka nhọrọ gị

Uru nke Igwe ịgbado ọkụ Laser ejiri aka

1. Oke ịgbado ọkụ:

Ejiri isi ịgbado ọkụ ejiri 10M nwere eriri ngwa anya izizi (ogologo ahaziri ogologo bụ 15M), nke na-emeri njedebe nke oghere ọrụ, enwere ike ịgbanye ya n'èzí na ịgbado ọkụ dị anya;

2. Dị mma na mgbanwe iji:

A na-eji akwa mgbanaka laser ejiri aka mee ya, nke dị mma ijide, ma nwee ike ịhazigharị ọdụ ụgbọ ahụ n'oge ọ bụla, na-enweghị ọdụ ebe a kapịrị ọnụ, nweere onwe ya ma na-agbanwe agbanwe, dabara adaba maka ọnọdụ dị iche iche na-arụ ọrụ.

3. Ọtụtụ ụzọ ịgbado ọkụ:

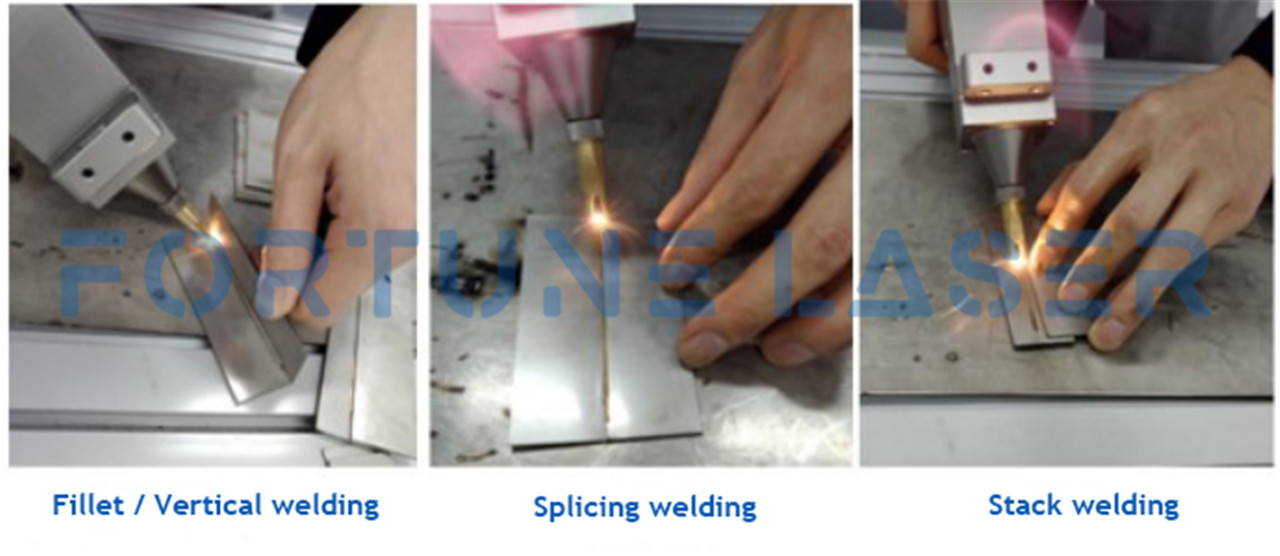

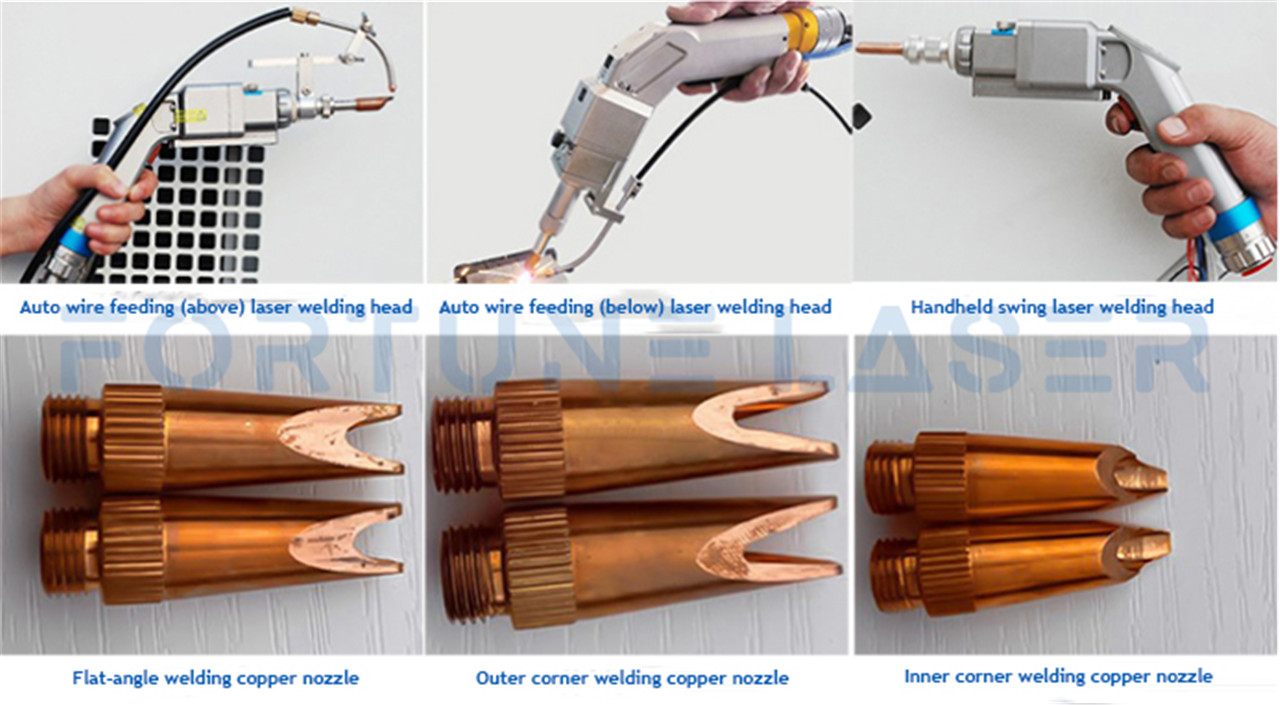

Ịgbado ọkụ n'akụkụ ọ bụla nwere ike na-aghọta: overlap ịgbado ọkụ, butt ịgbado ọkụ, vetikal ịgbado ọkụ, flat fillet ịgbado ọkụ, esịtidem fillet ịgbado ọkụ, mpụga fillet ịgbado ọkụ, wdg, na ike weld dị iche iche mgbagwoju welded ọrụ-ibe na nnukwu ọrụ-ibe na-adịghị mgbe shapes. Chọpụta ịgbado ọkụ n'akụkụ ọ bụla. Ke adianade do, ọ nwekwara ike mezue ọnwụ, ịgbado ọkụ na ọnwụ nwere ike Switched kpam kpam, dị nnọọ ịgbanwe ịgbado ọkụ ọla kọpa nozulu na ọnwụ ọla kọpa nozulu, nke dị nnọọ adaba.

4. Mmetụta ịgbado ọkụ dị mma:

Ịgbado ọkụ laser ejiri aka bụ ịgbado ọkụ ọkụ. E jiri ya tụnyere ịgbado ọkụ ọdịnala, ịgbado ọkụ laser nwere njupụta ume dị elu ma nwee ike nweta nsonaazụ ịgbado ọkụ ka mma. Ebe ịgbado ọkụ nwere obere mmetụta okpomọkụ, ọ dịghị mfe nrụrụ, oji, ma nwee akara na azụ. The ịgbado ọkụ omimi bụ nnukwu, na agbaze zuru ezu, na ọ bụ ike na a pụrụ ịdabere na, na weld ike erute ma ọ bụ karịa isi metal n'onwe ya, nke na-enweghị ike na-ekwe nkwa site nkịtị ịgbado ọkụ igwe.

5. Welding seams adịghị mkpa ka a na-egbu maramara.

Mgbe ịgbado ọkụ ọdịnala gasịrị, ọ dị mkpa ka a na-ehicha ebe a na-agbado ọkụ iji hụ na ọ dị ire ma ghara isi ike. Igwe ịgbado ọkụ laser ejiri aka na-egosipụta nke ọma na uru ndị ọzọ na mmetụta nhazi: ịgbado ọkụ na-aga n'ihu, dị nro na enweghị akpịrịkpa azụ, mara mma na enweghị ọnya, yana usoro polishing dị ole na ole.

6. Welding naakpaka waya feeder.

N'ihe ọtụtụ ndị mmadụ chere, ọrụ ịgbado ọkụ bụ "Ego elele aka ekpe, waya mgbado mgbado aka nri". Ma site na igwe ịgbado ọkụ laser ejiri aka, enwere ike ịmecha ịgbado ọkụ n'ụzọ dị mfe, nke na-ebelata ọnụ ahịa ihe na mmepụta na nhazi.

7. Nchekwa makaonye ọrụ.

Na otutu mkpuchi nchekwa, ọnụ ịgbado ọkụ na-arụ ọrụ naanị mgbe a na-emetụ ngbanwe ahụ aka mgbe ọ na-emetụ ígwè ahụ, na ọkụ na-akpaghị aka na-ekpochi mgbe e wepụrụ mpempe ọrụ ahụ, na ngbanwe mmetụ ahụ nwere mmetụta okpomọkụ. Nchekwa dị elu iji hụ na nchekwa nke onye ọrụ n'oge ọrụ.

8. Chekwaa ụgwọ ọrụ.

E jiri ya tụnyere ịgbado ọkụ arc, ọnụ ahịa nhazi nwere ike belata ihe dịka 30%. Ọrụ ahụ dị mfe, dị mfe ịmụta, yana ngwa ngwa ịmalite. Ọnụ ụzọ teknụzụ nke ndị na-arụ ọrụ adịghị elu. Ndị ọrụ nkịtị nwere ike ịmalite ọrụ ha mgbe obere ọzụzụ gasịrị, nke nwere ike nweta nsonaazụ ịgbado ọkụ dị elu ngwa ngwa.

9. Mfe ịgbanwe site na omenala ịgbado ọkụ ụzọ na eriri laser ịgbado ọkụ.

Ị nwere ike ịmụta otú e si eji Fortune Laser eriri laser ịgbado ọkụ igwe n'ime awa ole na ole, na ọ dịghị isi ọwụwa anya n'ihi na ịgbado ọkụ ọkachamara, enweghị nchegbu banyere uko nnyefe oge. Kedu ihe ọzọ, site na teknụzụ ọhụrụ a na itinye ego, ị ga-anọ n'ihu ahịa wee nabata oke uru karịa usoro ịgbado ọkụ ọdịnala.

Ubi ngwa nke igwe ịgbado ọkụ laser ejiri aka

The handheld laser welder bụ tumadi maka nnukwu na ọkara-sized mpempe akwụkwọ metal, cabinets, chassis, aluminum alloy ọnụ ụzọ na windo okpokolo agba, igwe anaghị agba nchara efere na ndị ọzọ na nnukwu ọrụ-ibe, dị ka n'ime ime n'akuku, mpụta nri akụkụ, flat weld ịgbado ọkụ, obere okpomọkụ-emetụta n'oge ịgbado ọkụ, obere deformation, na ịgbado ọkụ omimi Large, siri ike ịgbado ọkụ.

A na-eji igwe ịgbado ọkụ nke Fortune Laser handheld laser n'ọtụtụ ebe na usoro ịgbado ọkụ na mgbagwoju anya nke kichin na ụlọ ịsa ahụ, ụlọ ọrụ ngwa ụlọ, ụlọ ọrụ mgbasa ozi, ụlọ ọrụ ebu, ụlọ ọrụ igwe anaghị agba nchara, ụlọ ọrụ igwe anaghị agba nchara, ọnụ ụzọ na windo ụlọ ọrụ, ụlọ ọrụ aka, ụlọ ọrụ ngwongwo ụlọ, ụlọ ọrụ arịa ụlọ, ụlọ ọrụ akụrụngwa, wdg.

Ntụnyere igwe ịgbado ọkụ laser ejiri aka na Argon Arc Welding

1. Ntụle oriri ike:E jiri ya tụnyere ịgbado ọkụ ọdịnala, igwe ịgbado ọkụ laser ejiri aka na-echekwa ihe dịka 80% ruo 90% nke ike eletriki, yana ọnụ ahịa nhazi nwere ike belata ihe dịka 30%.

2. Welding mmetụta ntụnyere:ịgbado ọkụ n'aka laser nwere ike mezuo igwe anaghị agbado agbado na ụdị ịgbado ọkụ. Ọsọ dị ngwa ngwa, nrụrụ dị ntakịrị, na mpaghara okpomọkụ na-emetụta dị ntakịrị. Oghere weld ahụ mara mma, dị larịị, enweghị/obere porosity, na enweghị mmetọ. Enwere ike iji igwe ịgbado ọkụ laser ejiri aka mee obere akụkụ mepere emepe yana ịgbado ọkụ nkenke.

3. Ntụle usoro nleba anya:obere okpomọkụ ntinye n'oge ịgbado ọkụ aka laser, obere nrụrụ nke workpiece, mara mma ịgbado ọkụ elu nwere ike nweta, ọ dịghị ma ọ bụ naanị mfe ọgwụgwọ (dabere na chọrọ nke ịgbado ọkụ n'elu mmetụta). Igwe ịgbado ọkụ laser ejiri aka nwere ike belata ụgwọ ọrụ nke nnukwu polishing na nhazi ọkwa.

| Ụdị | Argon arc ịgbado ọkụ | YAG ịgbado ọkụ | EjidereLaserịgbado ọkụ | |

| Ogo ịgbado ọkụ | Ntinye ọkụ | Nnukwu | Obere | Obere |

|

| Nrụrụ / nbibi nke arụ ọrụ | Nnukwu | Obere | Obere |

|

| Weld na-akpụ | Ụkpụrụ ọ̀tụ̀tụ̀ azụ̀ | Ụkpụrụ ọ̀tụ̀tụ̀ azụ̀ | Dị nro |

|

| Nhazi na-esote | Polish | Polish | Ọ dịghị |

| Jiri ọrụ | Ọsọ ịgbado ọkụ | Nwayọọ nwayọọ | N'etiti | Ngwa ngwa |

|

| Ihe isi ike ọrụ | siri ike | Mfe | Mfe |

| Nchekwa gburugburu ebe obibi na nchekwa | Mmetọ gburugburu ebe obibi | Nnukwu | Obere | Obere |

|

| Imerụ ahụ | Nnukwu | Obere | Obere |

| Ọnụ ego welder | Ihe eji eme ihe | mkpanaka ịgbado ọkụ | Laser crystal, xenon oriọna | Enweghị isi |

|

| Oriri ike | Obere | Nnukwu | Obere |

| Mpaghara ala akụrụngwa | Obere | Nnukwu | Obere | |