Kev nyab xeeb thiab kev ua haujlwm ntawm cov tsheb ciav hlau niaj hnub no nyob ntawm kev tsim cov khoom kom zoo kawg nkaus cov qauv ntawm precision. Nyob rau hauv lub plawv ntawm cov txheej txheem kev lag luam no yog laser txiav, ib qho kev siv tshuab uas siv lub teeb tsom ntawm lub teeb los tsim cov khoom hlau nrog qhov tsis sib xws.

Phau ntawv qhia no muab cov ncauj lus kom ntxaws txog cov txheej txheem engineering uas tswj hwmlaser txiav, tshawb nrhiav nws cov ntawv thov sib txawv los ntawm lub tsheb ciav hlau mus rau cov khoom siv taug kev, thiab piav qhia vim li cas nws tau dhau los ua lub hauv paus cuab yeej rau kev lag luam tsheb ciav hlau.

Tshuab: Yuav ua li cas ib tug Laser txiav hlau

Nws tsis yog ib qho generic "beam of light".Cov txheej txheem yog kev tswj xyuas kev sib raug zoo ntawm lub teeb, roj, thiab hlau.

Ntawm no yog cov txheej txheem step-by-step:

1. tiam:Nyob rau hauv ib lub hwj chim qhov chaw, ib tug series ntawm diodes "tswj" lub zog rau hauv fiber optic cables uas tau doped nrog tsawg-lub ntiaj teb hais. Qhov no excites lub atoms thiab generates ib tug khaus, high-zog beam ntawm lub teeb.

2. Kev tsom xam:Cov nqaj no, feem ntau ntsuas ntawm 6 thiab 20 kilowatts (kW) rau hnyav kev lag luam siv, yog channeled los ntawm fiber ntau optic cable mus rau lub taub hau txiav. Nyob ntawd, ib lub koob yees duab tsom nws mus rau qhov chaw me me, muaj zog heev, qee zaum me dua 0.1 hli.

3.Cutting & Gas Pab:Lub tsom beam melts thiab vaporizes cov hlau. Nyob rau tib lub sijhawm, lub tshuab hluav taws xob siab pab tau raug rho tawm los ntawm tib lub nozzle raws li lub teeb laser. Cov roj no tseem ceeb heev thiab ua haujlwm rau ob lub hom phiaj: nws tshuab cov hlau molten huv si tawm ntawm qhov txiav (lub npe hu ua "kerf") thiab nws cuam tshuam qhov kev txiav zoo.

Nitrogen (N2)yog ib qho inert gas siv rau txiav stainless hlau thiab txhuas. Nws ua kom huv si zoo kawg nkaus, nyiaj, oxide-dawb ntug uas tam sim ntawd npaj rau vuam. Qhov no yog hu ua "high-pressure clean cut".

Cov pa oxygen (O2)yog siv los txiav carbon steel. Oxygen tsim cov tshuaj tiv thaiv exothermic (nws nquag kub hnyiab nrog cov hlau), uas tso cai rau kev txiav nrawm dua. Lub resulting ntug muaj ib txheej nyias ntawm oxide uas yog siv tau rau ntau daim ntaub ntawv.

Daim Ntawv Thov: Los ntawm Main Ncej mus rau Micro-Components

Laser txiav tshuab yog siv thoob plaws hauv tag nrho cov txheej txheem kev tsheb ciav hlau, los ntawm cov txheej txheem loj heev uas ua kom cov neeg caij tsheb muaj kev nyab xeeb mus rau qhov tsawg tshaj plaws, feem ntau cov khoom siv sab hauv. Kev siv thev naus laus zis ntau yam tso cai rau nws siv rau ntau qhov chaw, qhia nws lub luag haujlwm tseem ceeb hauv kev tsim tsheb ciav hlau niaj hnub thiab cov txheej txheem uas txhawb nqa lawv.

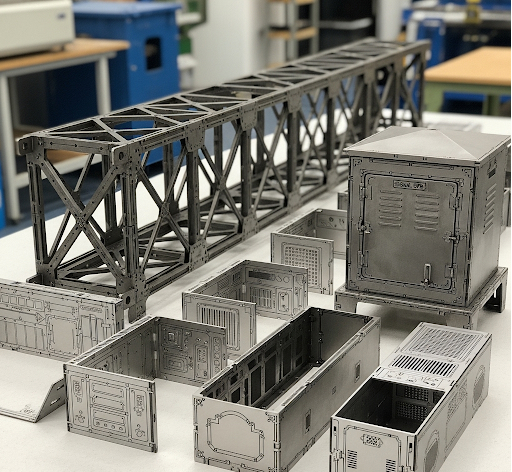

Cov yam ntxwv ntawm tus qauv:Nov yog thaj chaw tseem ceeb tshaj plaws. Lasers yog siv los txiav lub ntsiab lub tsev thaiv ntawm lub tsheb ciav hlau, nrog rau lub tsheb lub cev plhaub, lub luag hauj lwm hnyav underframes uas txhawb nqa hauv pem teb, thiab kev nyab xeeb-tseem ceeb bogie Cheebtsam xws li sab ncej, hla kab, thiab bolsters. Cov no feem ntau yog tsim los ntawm cov ntaub ntawv tshwj xeeb xws li lub zog siab qis-alloy steel, corten steel rau corrosion kuj, los yog 5000 thiab 6000 series aluminium alloys rau lub teeb yuag high-speed tsheb ciav hlau.

Sab hauv thiab Sub-Systems:Precision yog qhov tseem ceeb ntawm no thiab. Qhov no suav nrog stainless hlau HVAC ducting uas yuav tsum haum rau hauv qhov chaw nruj, aluminium qab nthab thiab phab ntsa vaj huam sib luag nrog cov kev txiav tawm meej rau lub teeb thiab hais lus, rooj zaum thav duab, thiab galvanized steel enclosures rau rhiab electronics.

Infrastructure thiab chaw nres tsheb:Daim ntawv thov txuas ntxiv dhau lub tsheb ciav hlau lawv tus kheej. Lasers txiav cov hlau hnyav rau catenary masts, cov vaj tse rau cov khoom siv taw qhia, thiab cov vaj huam sib luag nyuaj siv los kho cov chaw nres tsheb facades.

Qhov Precision Advantage: Qhov tob tob

Lub sij hawm "precision" muaj cov txiaj ntsig engineering uas tau dhau mus dhau qhov "zoo haum".

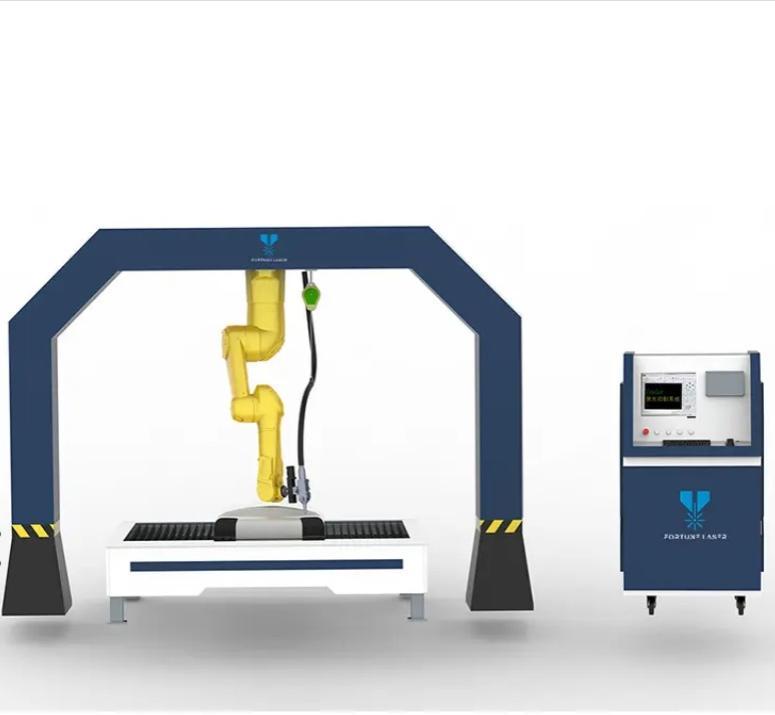

Enabling Robotic Automation:Qhov tshwj xeeb sib xws ntawm laser-txiav qhov chaw yog qhov ua rau kev kub ceev robotic vuam qhov tseeb. Lub vuam neeg hlau ua raws li txoj hauv kev, pre-programmed txoj kev thiab tsis tuaj yeem hloov mus rau qhov sib txawv ntawm cov khoom. Yog hais tias ib feem yog ib millimeter tawm ntawm qhov chaw, tag nrho cov weld tuaj yeem ua tsis tiav. Vim hais tias laser txiav tsim cov khoom seem zoo ib yam txhua lub sijhawm, nws muab qhov kev ntseeg siab tsis muaj zog uas cov tshuab siv hluav taws xob xav tau los ua haujlwm seamlessly thiab zoo.

Kev txo qis ntawm Heat-Affected Zone (HAZ):Thaum koj txiav hlau nrog cua sov, thaj tsam ib ncig ntawm qhov txiav kuj tau kub, uas tuaj yeem hloov nws cov khoom (xws li ua rau nws nkig). Qhov no yog Heat-Affected Zone (HAZ). Vim hais tias lub laser yog li ntawd tsom, nws qhia me ntsis cua sov rau hauv ib feem, tsim ib tug me me HAZ. Qhov no yog ib qho tseem ceeb heev vim hais tias nws txhais tau hais tias cov qauv kev ncaj ncees ntawm cov hlau nyob ib sab ntawm qhov txiav tseem tsis hloov, kom ntseeg tau tias cov khoom ua tau raws nraim li cov engineers tsim nws.

Kev Lag Luam Case: Quantifying cov txiaj ntsig

Cov tuam txhab tsis nqis peev ntau lab hauv cov thev naus laus zis no vim nws yog qhov tseeb. Cov nyiaj txiag thiab logistical rov qab yog qhov tseem ceeb.

Advanced Material Siv:Smart "zes" software yog qhov tseem ceeb. Nws tsis tsuas yog haum rau qhov chaw ua ke zoo li cov duab dhos ua si tab sis kuj siv cov txheej txheem siab heev xws li cov kab txiav, qhov twg ob qhov chaw nyob ib sab raug txiav nrog ib kab, tshem tawm tag nrho cov seem ntawm lawv. Qhov no tuaj yeem thawb kev siv cov khoom siv los ntawm 75% mus rau ntau dua 90%, txuag nyiaj ntau ntawm cov nqi raw khoom.

"Lights-Out" Manufacturing:Niaj hnub nimno laser cutters feem ntau ua ke nrog automated loading / unloading yees. Cov tshuab no tuaj yeem tuav tau kaum ob nplooj ntawv ntawm cov khoom siv raw thiab khaws cov khoom tiav. Qhov no tso cai rau lub tshuab ua haujlwm tsis tu ncua thaum hmo ntuj thiab hnub so nrog kev saib xyuas tib neeg tsawg-ib lub tswv yim hu ua "teeb-tawm" kev tsim khoom-ua kom cov khoom tsim tau zoo heev.

Streamlining tag nrho Workflow:Cov txiaj ntsig sib npaug hauv qab.

1. Tsis muaj Deburring:Ib qho kev txiav thawj zaug huv si tshem tawm qhov xav tau ntawm qhov chaw sib tsoo thib ob kom tshem tawm cov npoo ntse. Qhov no ncaj qha txuag cov nqi zog, txhim kho kev nyab xeeb ntawm cov neeg ua haujlwm los ntawm kev tshem tawm kev sib tsoo, thiab ua kom lub zog ua haujlwm tag nrho.

2. Tsis muaj Rework:Precisely txiav qhov kom ib tug zoo meej haum, tshem tawm lub sij hawm-nkim phau ntawv hloov kho thaum sib dhos. Qhov no ncaj qha accelerates ntau lawm ceev, nce throughput, thiab ua rau ib tug zoo dua-zoo kawg khoom.

3. Simplified Supply Chain:Kev txiav cov khoom raws li qhov xav tau los ntawm cov ntaub ntawv digital txo qhov xav tau los khaws cov khoom lag luam loj, txo cov nqi cia, txo cov khoom pov tseg, thiab ua kom muaj kev ua haujlwm nrawm.

Lub Tuam Txhab Zoo rau Txoj Haujlwm: Kev Sib Txuas Ntxiv

Kev xaiv cov cuab yeej zoo tshaj plaws nyob rau hauv ib puag ncig kev tsim khoom yog txiav txim siab los ntawm kev txheeb xyuas ntau qhov sib txawv ntawm kev tsim ceev, kev ua siab ntev, kev ua haujlwm, thiab cov khoom siv. Yog li ntawd, lub laser tsis yog ib qho kev daws teeb meem universally.

| Txoj kev | Zoo tshaj rau | Qhov tseem ceeb tshaj | Qhov Tseem Ceeb Disadvantage |

| Fiber Laser Tej Tshuab | High-precision txiav ntawm nplooj ntawv mus txog ~ 25mm (1 nti) tuab. Zoo tagnrho rau stainless hlau thiab txhuas. | Tsis sib xws precision, huv npoo, me me HAZ, thiab kev kub ceev ntawm cov ntaub ntawv nyias. | Tus nqi pib siab heev. Tsis zoo li cov phaj tuab heev. |

| Plasma | Txiav tuab steel phaj (> 25mm) sai sai qhov zoo meej ntug zoo tsis yog qhov tseem ceeb tshaj plaws. | Kev txiav ceev heev ntawm cov ntaub ntawv tuab thiab qis tus nqi pib dua li lub zog laser. | HAZ loj dua, tsis tshua muaj meej, thiab ua rau lub beveled ntug uas feem ntau yuav tsum tau sib tsoo. |

| Dej dav hlau | Txiav txhua yam khoom (hlau, pob zeb, iav, composites) yam tsis muaj cua sov, tshwj xeeb tshaj yog kub-rhiab alloys lossis hlau tuab heev. | Tsis muaj HAZ txhua, tsis tshua muaj kev sib tw ua tiav, thiab cov khoom siv tau zoo heev. | Ntau qeeb dua laser lossis plasma, thiab muaj cov nqi khiav lag luam ntau dua vim muaj kev sib txhuam thiab kev tu lub twj tso kua mis. |

Hauv kev xaus, fiber ntau laser txiav yog ntau tshaj li ib txoj kev rau shaping hlau; Nws yog lub hauv paus thev naus laus zis hauv digital manufacturing ecosystem ntawm kev lag luam railway niaj hnub. Nws tus nqi yog nyob rau hauv kev sib xyaw ua ke muaj zog ntawm huab cua precision, high-speed ntau lawm, thiab sib sib zog nqus kev koom ua ke nrog lub Hoobkas thoob plaws lub tshuab.

Los ntawm kev ua kom muaj kev ua haujlwm siab tshaj plaws xws li kev sib txuas cov neeg hlau, txo qhov kub ntawm qhov cuam tshuam los tiv thaiv cov khoom siv zog, thiab muab cov ntug tsis zoo uas yuav tsum tau ua kom tau raws li cov qauv kev nyab xeeb nruj xws li EN 15085, nws tau dhau los ua cov cuab yeej tsis sib tham.

Thaum kawg, laser txiav muab cov engineering tseeb thiab kev ruaj ntseg zoo tsim nyog los tsim kom muaj kev nyab xeeb, txhim khu kev qha, thiab thev naus laus zis kev tsheb ciav hlau niaj hnub no.

Post lub sij hawm: Aug-22-2025