Fortune Laser Mini 1000W / 1500W / 2000W 3 Hauv 1 Fiber Handheld Laser Vuam Tshuab

Fortune Laser Mini 1000W / 1500W / 2000W 3 Hauv 1 Fiber Handheld Laser Vuam Tshuab

Nyob rau tib lub sijhawm, lub tshuab me me laser vuam tshuab txhawb kev txiav thiab vuam tib lub sijhawm thiab cov txheej txheem xaim xaim tshuab, uas tuaj yeem txo qhov kev xav tau ntawm cov khoom seem thiab txhim kho vuam zoo. Nws kuj tseem tuaj yeem siv nrog kev sib koom ua ke ntawm cov neeg hlau los txhim kho lub vuam teeb ntawm cov neeg hlau sib koom ua ke, txo cov neeg ua haujlwm kev siv zog thiab txhim kho cov vuam zoo ntawm cov vuam.

1000W 1500w 2000w 3000W Mini Laser Vuam Tshuab Advantage

All-in-one chassis tsim yog yooj yim

Fortunelaser tes tuav fiber ntau laser vuam tshuab txais kev tsim ntawm lub txee ua ke, uas ua ke nrog lub laser, chiller, software tswj, thiab lwm yam, thiab muaj qhov zoo ntawm me me hneev taw, yooj yim txav, thiab muaj zog ua haujlwm.

Hloov chaw "txoj kev kho qhov muag", kev ua haujlwm yooj yim dua.

Tam sim no tes tuav welding, siv rab phom welding tes los hloov txoj kev kho qhov muag, kev ua haujlwm yog yooj yim dua, tawg los ntawm cov kev txwv ntawm lub workbench, kom tau raws li cov vuam ntawm ntau lub kaum ntse ntse thiab txoj haujlwm. Tsis tas li ntawd, infrared positioning yog siv rau qhov tseeb dua thiab calibration ntawm vuam txoj hauj lwm kom ntseeg tau tias zoo nkauj welds.

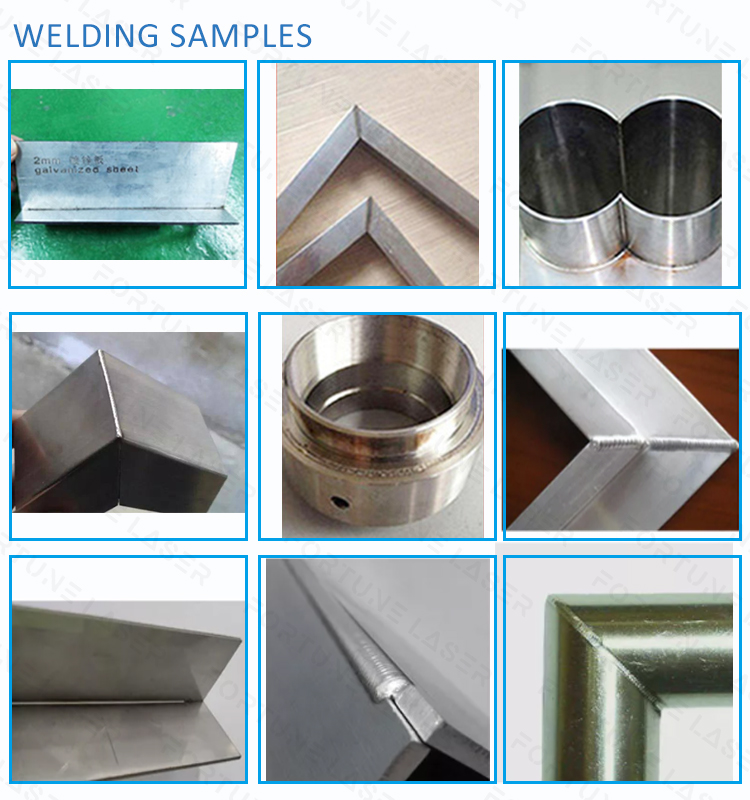

Me thermal deformation, du thiab zoo nkauj weld

Peb tuaj yeem pom tias vuam seam ntawm lub tshuab fiber ntau optical tuav laser vuam tshuab yog du thiab zoo nkauj, lub vuam workpiece tsis muaj deformation, tsis muaj vuam caws pliav, thiab vuam yog ruaj khov, txo cov txheej txheem sib tsoo tom ntej, txuag sijhawm thiab nqi. Kev siv vuam tsoos yog qhov nyuaj rau kev ua tiav qhov zoo nkauj ntawm vuam ntawm cov workpieces nyuaj, thaum tuav vuam tuaj yeem ua tiav cov ces kaum, sib npaug thiab ntau txoj kev vuam, ua rau vuam yooj yim dua.

Lub vuam qhov tob yog qhov loj thiab qhov vuam yog ruaj khov

Lub tes tuav fiber ntau laser vuam tshuab yog tsuas yog siv rau laser vuam ntawm ntev-ntev thiab loj workpieces. Lub tshav kub cuam tshuam qhov chaw thaum lub vuam yog me me, uas yuav tsis ua rau kev ua haujlwm deformation, blackening, thiab kab nyob tom qab. Lub vuam qhov tob yog qhov loj, qhov vuam yog ruaj, thiab cov melting yog txaus.

Ib lub tshuab txhawb nqa peb txoj haujlwm ntawm vuam, txiav thiab tu

Kev hloov dua siab tshiab ntawm 3 lub zog tuaj yeem pom tau los ntawm lub taub hau laser nkaus xwb.

Fortune Laser Mini Laser Vuam Tshuab Technical Parameters

| Qauv | FL-HWM 1000 M | FL-HWM 1500 M | FL-HW 2000M |

| Laser zog | 1000 W | 1500 W | 2000 W |

| Txoj kev txias | Dej Txias | Dej Txias | Dej Txias |

| LaserWavelength kev | 1080 uanm | 1080 uanm | 1080 uanm |

| Wua haujlwm | Ctsis tu ncua/Modulation | ||

| Fiber Length | Standard 10m, qhov ntev customized ntev 15m | ||

| Dimension | 100 * 68 * 45cm | ||

| Wyim | 165kg ua | ||

| Kev xaiv | Portable | ||

| Ceev ntau ntawm welder | 0-120mm / s | ||

| Kub | 15-35 ℃ | ||

| Kev khiav hauj lwm voltage | AV 220V | ||

| Focal Spot Diameter | 0.5 hli | ||

| Vuam thickness | 0.5-5 hli | ||

Nta

l Cov yam ntxwv tseem ceeb: tus kheej tsim peb-hauv-ib qho kev tswj hwm, hloov pauv hloov pauv ntawm vuam, ntxuav, thiab txiav, ntau lub tswb nrov, kev ua haujlwm yooj yim thiab yoog raws.

l Ntau ruaj khov: Txhua qhov tsis pom kev, kev saib xyuas lub sijhawm tiag tiag ntawm cov xwm txheej ntawm lub tshuab tag nrho, tsis txhob muaj teeb meem ua ntej, pab daws teeb meem thiab daws teeb meem, thiab ua kom muaj kev ruaj ntseg ntawm lub kaw lus.

l Txheej Txheem: Cov txheej txheem tsis tuaj yeem teeb tsa, thiab ntau yam txheej txheem tuaj yeem sim ua kom yooj yim.

l Cov tsis ruaj khov thiab rov ua haujlwm siab: Qhov kev txiav txim siab nozzle cua siab thiab lub lens lub xeev, tsuav yog lub zog laser ruaj khov, cov txheej txheem yuav tsum tau rov ua dua, uas ua rau muaj txiaj ntsig zoo.

| Kev them nyiaj yug voltage (V) | 220V ± 10% AC 50/60Hz |

| Qhov chaw ib puag ncig | Pav ca, tsis muaj kev vibration thiab poob siab |

| Ua haujlwm ib puag ncig kub (℃) | 10~40 |

| Ua hauj lwm ib puag ncig humidity (%) | <70 |

| Txoj kev ua kom txias | Dej txias |

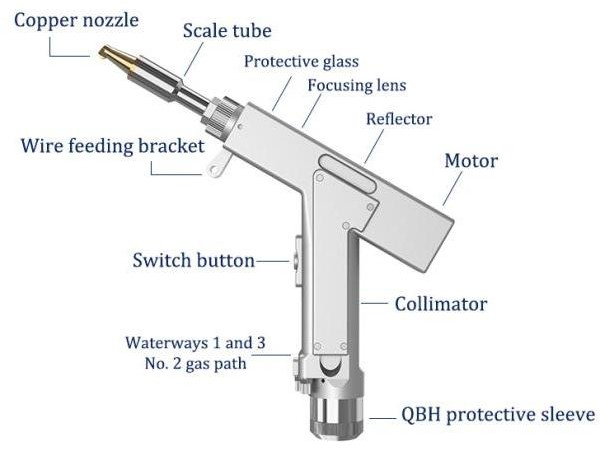

| Collimation | D20 * 5 / F60 |

| Ua kom pom tseeb (kev tuav tes vuam hom) | D20 * 4.5 / F150 |

| Ua kom pom tseeb (hloov hom) | D20 * 4.5 / F400 |

| Kev xav | 30 * 14 T2 |

| Protective lens specifications | 18 * 2 |

| Kev txhawb siab siab tshaj plaws | 10 Bar |

| Ua kom pom tseeb ntsug hloov ntau yam | ± 10 hli |

| Spot adjustment range (handwelding mode) | 0 x6mm |

| Spot adjustment range (cleaningmode) | 0 ~ 50mm |