ʻO Fortune Laser Handheld Fiber Laser Welding Machine

ʻO Fortune Laser Handheld Fiber Laser Welding Machine

ʻO Fortune Laser Handheld Laser Welder Technical Parameters

| Hoʻohālike | FL-HW1000 | FL-HW1500 | FL-HW2000 |

| ʻAno Laser | 1070nm Fiber Laser | ||

| Mana Laser inoa | 1000W | 1500W | 2000W |

| Pūnaehana hoʻoluʻu | Hooluu wai | ||

| Ke ala hana | Hoʻomau / Modulation | ||

| Ka wikiwiki o ka welder | 0~120 mm/s | ||

| Anawaena kiko kiko | 0.5mm | ||

| Laulā wela ambient | 15~35 ℃ | ||

| Laina haʻahaʻa kaiapuni | <70% me ka condensation ole | ||

| mānoanoa welding | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| ʻO ke koina o ka welding gap | ≤1.2mm | ||

| Voltage Hana | AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

| Ka Aha Kuhina | 120*60*120cm | ||

| Laau Puolo Ana | 154*79*137cm | ||

| Kaumaha | 285KG | ||

| Ka lōʻihi o ka fiber | 10M maʻamau, ʻo 15M ka lōʻihi lōʻihi | ||

| Palapala noi | ʻO ke kuʻi ʻana a me ka hoʻoponopono ʻana i ke kila kila, ke kila kalapona, ka alumini alumini. | ||

Welder Laser Paʻa Paʻa no nā Metala

| Mea waiwai | Mana puka (W) | Ke komo kiʻekiʻe loa (mm) |

| Kila kohu ʻole | 1000 | 0.5-3 |

| Kila kohu ʻole | 1500 | 0.5-4 |

| Kila kohu ʻole | 2000 | 0.5-5 |

| Ke kila kalapona | 1000 | 0.5-2.5 |

| Ke kila kalapona | 1500 | 0.5-3.5 |

| Ke kila kalapona | 2000 | 0.5-4.5 |

| Aluminum huila | 1000 | 0.5-2.5 |

| Aluminum huila | 1500 | 0.5-3 |

| Aluminum huila | 2000 | 0.5-4 |

| Pepa uʻi | 1000 | 0.5-1.2 |

| Pepa uʻi | 1500 | 0.5-1.8 |

| Pepa uʻi | 2000 | 0.5-2.5 |

ʻEkolu kala no kāu mau koho

Nā Pōmaikaʻi o ka Mīkini Welding Laser Paʻa

1. Laulā wiliwili ākea:

Hoʻokomo ʻia ke poʻo kuʻi lima lima me 10M fiber optical kumu (ʻo ka lōʻihi lōʻihi loa ʻo 15M), e lanakila ana i nā palena o ka wahi hana, a hiki ke welded ma waho a me ka wili lōʻihi;

2. Maʻalahi a maʻalahi e hoʻohana:

Hoʻokomo ʻia ka welding laser paʻa lima me nā pulleys hiki ke hoʻoneʻe ʻia, ʻoluʻolu ke paʻa, a hiki ke hoʻoponopono i ke kikowaena i kēlā me kēia manawa, me ka ʻole o ke kahua paʻa, manuahi a maʻalahi, a kūpono hoʻi no nā hiʻohiʻona kaiapuni hana.

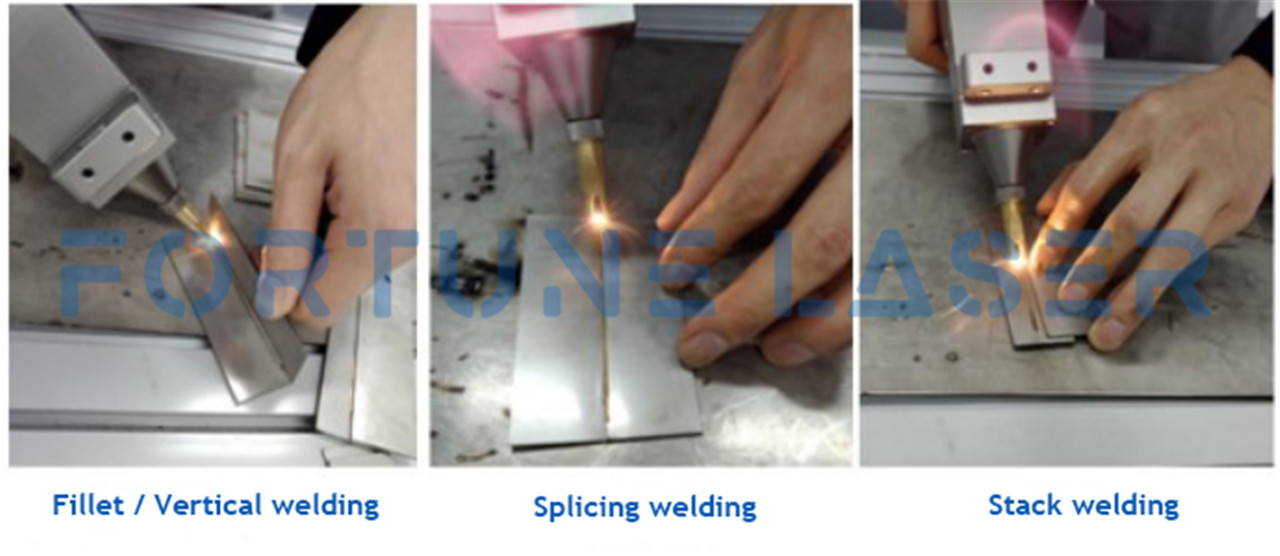

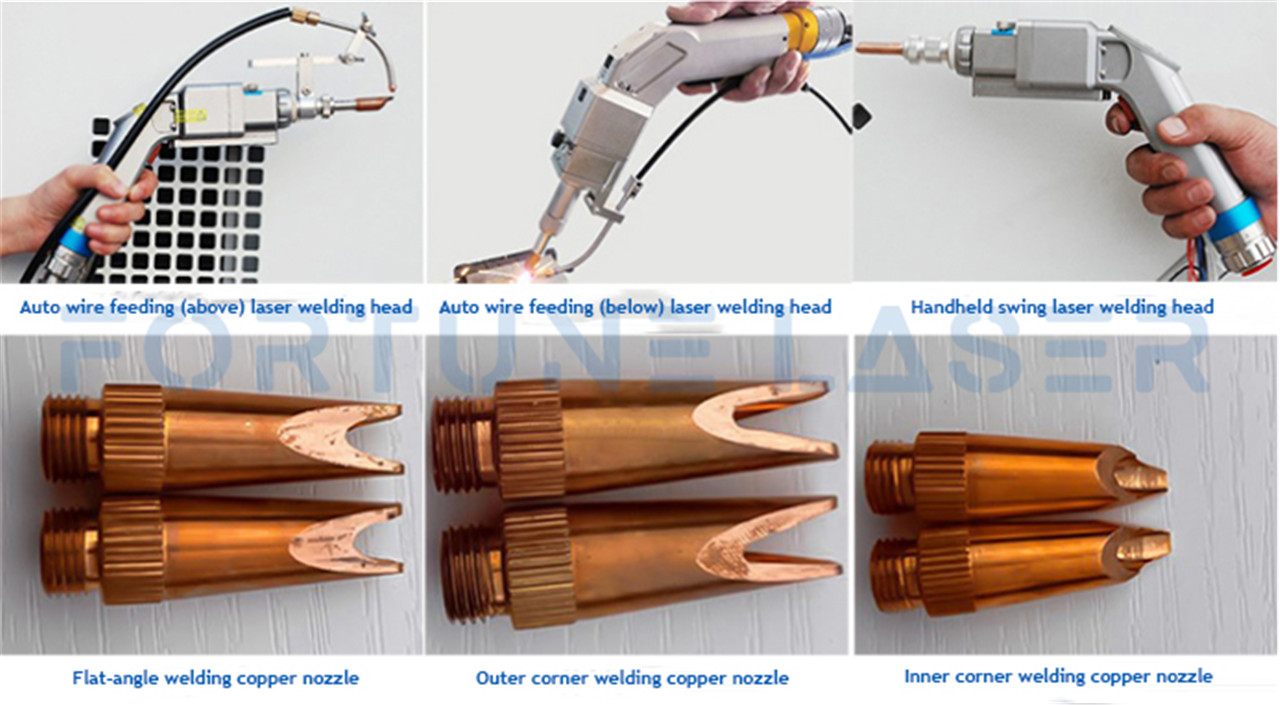

3. Nā ʻano hana kuʻihao he nui:

Hiki ke hoʻomaopopo ʻia ka welding ma kēlā me kēia kihi: overlap welding, butt welding, vertical welding, flat fillet welding, internal fillet welding, external fillet welding, etc. Hoʻomaopopo i ka wiliwili ma kēlā me kēia kihi. Eia kekahi, hiki iā ia ke hoʻopau i ka ʻokiʻoki, hiki ke hoʻololi manuahi a me ka ʻoki ʻana, e hoʻololi wale i ka nozzle keleawe welding i ka nozzle keleawe ʻoki, kahi mea maʻalahi loa.

4. Ka hopena kuʻihao maikaʻi:

ʻO ka hoʻoheheʻe ʻana i ka laser paʻa lima he wili wela wela. Ke hoʻohālikelike ʻia me ka wili kuʻuna, ʻoi aku ka nui o ka ikehu o ka welding laser a hiki ke hoʻokō i nā hopena wili maikaʻi. He liʻiliʻi ka hopena wela o ka wahi kuʻi, ʻaʻole maʻalahi ka deform, ʻeleʻele, a he ʻano ma ke kua. He nui ka hohonu o ka welding, lawa ka hoʻoheheʻe ʻana, a paʻa a hilinaʻi hoʻi, a ʻoi aku ka ikaika weld a ʻoi aku paha i ka metala kumu ponoʻī, ʻaʻole hiki ke hōʻoia ʻia e nā mīkini welding maʻamau.

5. ʻAʻole pono e poni ʻia ke kuʻi ʻana.

Ma hope o ka wili kuʻuna maʻamau, pono e hoʻomaʻamaʻa ʻia ka lae welding e hōʻoia i ka maʻalahi a ʻaʻole ʻoʻoleʻa. Hōʻike pololei ka welding laser paʻa lima i nā mea maikaʻi aʻe i ka hopena o ka hoʻoili ʻana: hoʻomau mau ʻia, ʻoluʻolu a ʻaʻohe unahi iʻa, nani a ʻaʻohe ʻōpala, a me nā kaʻina hana polishing hahai.

6. wiliwili memea hānai uea ʻakomi.

I ka hapanui o ka poʻe manaʻo, ʻo ka hana kuʻi ʻana he "lima hema goggles, uea kuʻi lima ʻākau". Akā me ka mīkini wili laser paʻa lima, hiki ke hoʻopau maʻalahi ka welding, e hōʻemi ana i ke kumukūʻai waiwai i ka hana a me ka hana.

7. Palekana nomea hoʻohana.

Me nā mea hoʻāla palekana he nui, ʻoi aku ka maikaʻi o ka welding tip ke hoʻopā ʻia ke kua i ka wā e hoʻopā ai i ka metala, a paʻa ʻia ke kukui ma hope o ka wehe ʻana o ka mea hana, a ʻo ka hoʻololi hoʻopā ʻana he ʻike wela ke kino. He kiʻekiʻe ka palekana e hōʻoia i ka palekana o ka mea hana i ka wā o ka hana.

8. Mālama i ka uku hana.

Ke hoʻohālikelike ʻia me ka arc welding, hiki ke hoʻemi ʻia ke kumukūʻai hana ma kahi o 30%. He maʻalahi ka hana, maʻalahi e aʻo, a wikiwiki hoʻi e hoʻomaka. ʻAʻole kiʻekiʻe ka paepae ʻenehana o nā mea hana. Hiki i nā limahana maʻamau ke lawe i kā lākou mau pou ma hope o kahi hoʻomaʻamaʻa pōkole, hiki ke maʻalahi i nā hopena welding kiʻekiʻe.

9. E hoʻololi maʻalahi mai nā ʻano kuʻuna kuʻuna i ka welding laser fiber.

Hiki iā ʻoe ke aʻo pehea e hoʻohana ai i ka Fortune Laser fiber laser welding machine i loko o kekahi mau hola, a ʻaʻohe poʻo poʻo e ʻimi i nā loea wili, ʻaʻohe hopohopo e pili ana i ka papa kuhikuhi paʻa. ʻO ka mea hou aʻe, me kēia ʻenehana hou a me ka hoʻopukapuka kālā, e ʻoi aku ʻoe ma mua o ka mākeke a apo i nā ʻāpana kālā i hoʻonui ʻia ma mua o nā ʻano kuʻuna kuʻuna.

Nā Māhele Noi o ka Mīkini Welding Laser Paʻa

ʻO ka welder laser paʻa lima no ka nui a me ka liʻiliʻi nui o ka metala, nā keʻena, nā chassis, ka puka alumini alumini a me nā puka makani, nā kīʻaha holoi kila kila a me nā ʻāpana hana nui ʻē aʻe, e like me ke kihi ʻākau o loko, ka ʻaoʻao ʻākau o waho, ka weld weld flat, wahi liʻiliʻi wela i ka wā welding, liʻiliʻi deformation, a me ka hohonu wili.

Hoʻohana nui ʻia nā mīkini hoʻoheheʻe lima lima ʻo Fortune Laser i nā kaʻina wiliwili paʻakikī a paʻakikī ʻole o ka lumi kuke a me ka ʻoihana lumi ʻauʻau, ka ʻoihana home appliance, ʻoihana hoʻolaha, ʻoihana mold, ʻoihana huahana kila kila, ʻoihana ʻenekinia kila, ʻoihana puka a me nā puka makani, ʻoihana lima lima, ʻoihana hale, ʻoihana lako, ʻoihana ʻāpana kaʻa, etc.

Hoʻohālikelike i ka Mīkini Welding Laser Paʻa a me Argon Arc Welding

1. Hoʻohālikelike hoʻohana ikehu:Ke hoʻohālikelike ʻia me ka kuʻuna arc kuʻuna, ʻo ka mīkini hoʻoheheʻe laser paʻa lima e mālama ma kahi o 80% a 90% o ka ikehu uila, a hiki ke hoʻemi ʻia ke kumukūʻai hana ma kahi o 30%.

2. Hoʻohālikelike hopena welding:hiki ke hoʻopaʻa lima lima laser ke hoʻopau i ke kila ʻokoʻa a me ka wili metala ʻokoʻa. He wikiwiki ka wikiwiki, liʻiliʻi ka deformation, a liʻiliʻi ka wahi i hoʻopili ʻia i ka wela. He nani, paheʻe, ʻaʻohe porosity, ʻaʻohe haumia. Hiki ke hoʻohana ʻia ka mīkini hoʻoheheʻe laser lima no nā ʻāpana liʻiliʻi liʻiliʻi a me ka wili pololei.

3. Hoʻohālikelike kaʻina hana hahai:ka hoʻokomo wela haʻahaʻa i ka wā o ka hoʻopaʻa lima lima laser, ka liʻiliʻi deformation o ka mea hana, hiki ke loaʻa ka ʻili kuʻi nani, ʻaʻole a i ʻole ka maʻalahi maʻalahi (e pili ana i nā koi o ka hopena o ka welding surface). Hiki i ka mīkini welding laser paʻa ke hoʻemi nui i ke kumukūʻai hana o ke kaʻina hana polishing a me ka pae.

| ʻAno | Argon arc welding | YAG wiliwili | Paʻa limaLaserwiliwili | |

| ʻO ka maikaʻi wili | Hoʻokomo wela | Nui | Liʻiliʻi | Liʻiliʻi |

|

| ʻO ka hoʻololi ʻana o ka mea hana | Nui | Liʻiliʻi | Liʻiliʻi |

|

| Welina hana | ʻano ʻano unahi iʻa | ʻano ʻano unahi iʻa | Maalahi |

|

| ʻO ka hana ma hope | Pōlani | Pōlani | ʻAʻohe |

| E hoʻohana i ka hana | Ka māmā wiliwili | lohi | Waena | wikiwiki |

|

| Paʻakikī hana | Paʻakikī | maʻalahi | maʻalahi |

| Ka palekana a me ka palekana | haumia kaiapuni | Nui | Liʻiliʻi | Liʻiliʻi |

|

| Poino kino | Nui | Liʻiliʻi | Liʻiliʻi |

| Koki welder | Mea hoopau | lāʻau wiliwili | ʻO ke aniani laser, kukui xenon | ʻAʻole pono |

|

| Hoʻohana ikehu | Liʻiliʻi | Nui | Liʻiliʻi |

| ʻāpana papahele o nā lako | Liʻiliʻi | Nui | Liʻiliʻi | |