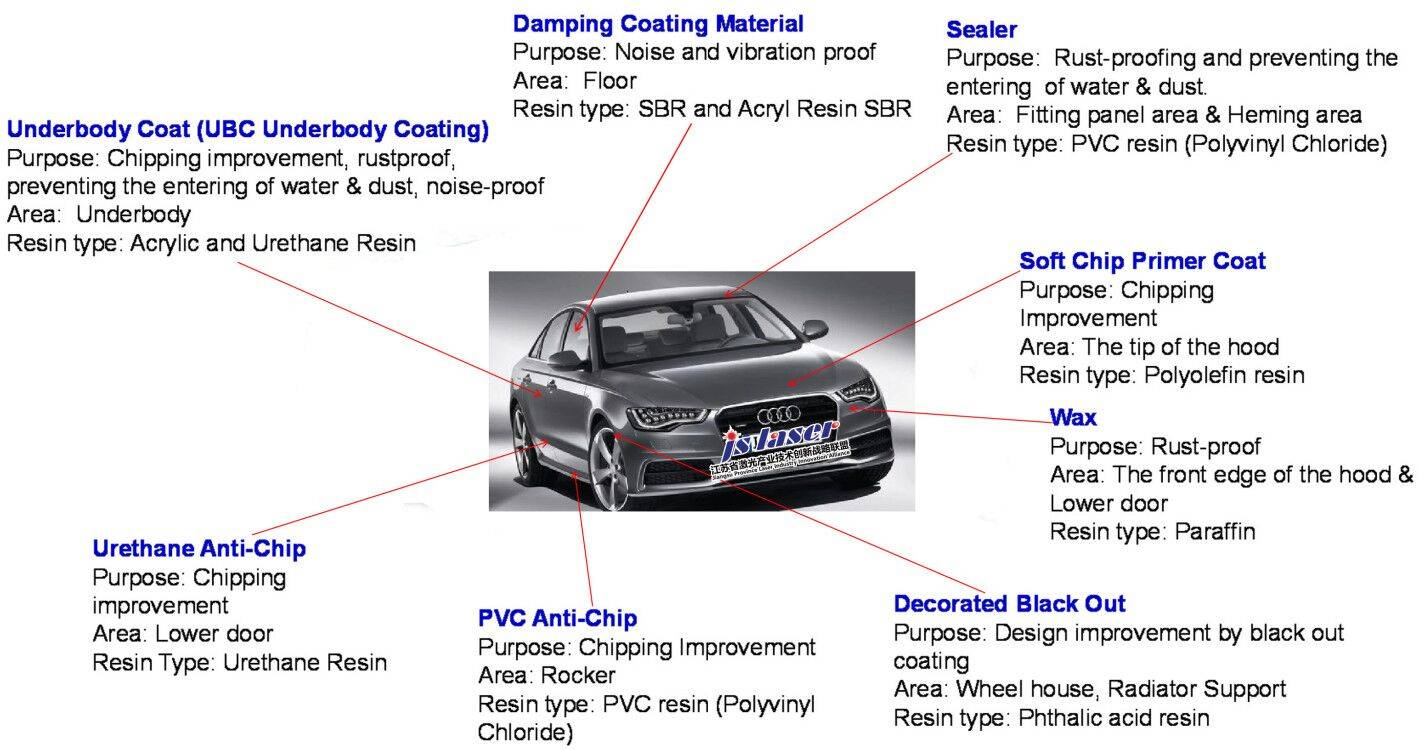

A cikin tsarin kera motoci, zana man shafawa ko sanyaya mai da mai da ake amfani da shi na hana tsatsa na iya gurɓata abubuwan kera motoci kuma suna ƙasƙantar da ingancin hanyoyin haɗaɗɗiyar ƙarfi mai ƙarfi ko haɗin kai. A cikinstsari, welds da shaidu a powertrain aka gyara dole ne m ingancin nagartacce an hadu. Sabili da haka, dole ne a tsaftace wuraren haɗin gwiwa sosai.

Me ya sa mutane da yawa mueLaser tsaftacewa don maye gurbin gargajiya tsaftacewa? Menene bambanci tsakanin tsaftacewa Laser da tsaftacewa na gargajiya a aikace-aikacen mota?

A cikin masana'antar kera motoci, ana buƙatar cire tsohon fentin da ke saman ta yadda za a iya shafa sabon fenti kafin a gyara jiki.

Akwai hanyoyin tsaftace fenti na jikin mota da yawa na gargajiya, galibi sun haɗa da hanyoyin inji da sinadarai. Don hanyoyin injuna, sun haɗa da cire fenti mai ƙarfi na ruwa jet, fashewar yashi da goga na ƙarfe. Kuma hanyoyin sinadarai galibi suna nufin abubuwan da ake amfani da su don cire fenti. Wadannan hanyoyin suna da lahani irin su tsada, yawan amfani da makamashi, gurɓataccen gurɓataccen abu, da sauƙi na lalacewa ga farfajiyar ƙasa, kuma a hankali sun kasa cika ka'idodin zamani don kare muhalli na hanyoyin tsaftacewa.

The azumi, sarrafa kansa yanayi na Laser tsaftacewa damar domin sosai tsaftacewa na surface sharan gona, sakamakon da karfi, banza- da micro-crack-free welds da shaidu. Bugu da kari, Laser tsaftacewa ne m da kuma tsari ne muhimmanci sauri fiye da sauran hanyoyin, abũbuwan amfãni da cewa an gane da mota masana'antu.

A cikin masana'antu, don kare karfe ko wasu kayan aiki, ana fentin saman gabaɗaya don hana tsatsa, oxidation, da lalata. Lokacin da fentin fenti ya ɗan cire ko kuma ana buƙatar fenti don wasu dalilai, asalin fentin ɗin yana buƙatar tsaftacewa gaba ɗaya.

Dangane da wannan yanayin, yawancin sabbin fasahohin tsaftacewa sun fito, kuma tsaftacewar laser, a matsayin ɗayan mahimman hanyoyin, sannu a hankali ya nuna fifikonsa. Daidai, za mu gabatar da aikace-aikacen tsaftacewa naLaser tsaftacewa inji a cikin mota masana'antu.

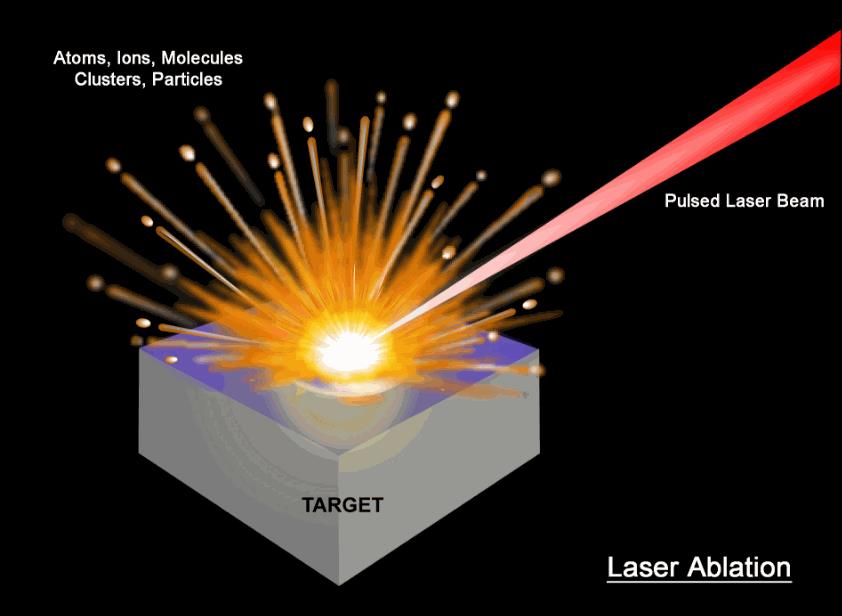

1. Akwai in mun gwada da cikakken tsari gacire fenti a samanna motoci da kuma tsari don cire fari don faranti na karfe. Laser katako ana daukar kwayar cutar ta hanyar fiber na gani kuma ana ci gaba da duba shi don cire fenti da fenti a saman farantin karfe, yana barin wuri mai tsabta a saman farantin karfe, wanda ya dace da sake fenti ko ci gaba da wasu matakai.

Yin amfani da wannan fasahar tsaftacewa ta Laser don tsaftace fakitin birki na mota shine cikakkiyar madaidaici ga tsaftacewa ta gargajiya. Tsarin tsaftar gargajiya na birki na mota, kamar fashewar yashi, ba shi da daɗi don tsaftace ɓangaren baya. Yin amfani da fasahar tsaftacewa na Laser mai daidaitawa zai iya cimma hanya mai sarrafa kansa don tsaftace farantin baya na kushin birki don saduwa da tsarin shafi na gaba. Zaɓar cirewa, babu lalacewa mai lalacewa, da ƙimar tsaftacewa da sauri sune mahimman abubuwan da ke ba da damar fenti na tsaftace Laser.

2. Lokacin da tsofaffin motocin mutane ke buƙatar gyara don dawo da kyawunsu na asali ko kuma gyara tsoffin kayansu, tare da ƙara ƙarfin laser.Laser tsaftacewa fasahazai taka rawar gani sosai. Tsabtace Laser na yau na iya tsaftacewa da cire tsofaffin wuraren da ba'a so akan kusan kowane tsoffin sassan mota. Misali, ko da chrome-plated surface Layer ana iya cire shi daidai. Yawanci, saman abin da aka rufe da yanayin abin hawa yana buƙatar cirewa gaba ɗaya kafin a shafa sabon fenti. Tun da kayan jiki da na sinadarai na saman saman fenti sun bambanta da na farko, ana iya saita iko da mita na laser don cire kawai saman saman fenti.

Novel waldi dabaru ko shiga tafiyar matakai soma a cikin ci gaba da} ir} na mota fasaha na bukatar cikakken pre-jiyya na welded ko shiga saman, kuma a wannan lokaci Laser tsaftacewa iya samar da bushe, daidai da kuma wadanda ba abrasive Cleaning magani, yayin da gargajiya rigar sinadaran tsaftacewa ko inji nika magani hanyoyin sau da yawa wuya saduwa, da kuma mafi sassa yanzu Laser tsabtace.

KumaLaser tsaftacewa yana da yawa abũbuwan amfãnikan tsaftar gargajiya:

1. Layin taro mai sarrafa kansa: Ana iya haɗa na'urar tsaftacewa ta Laser tare da kayan aikin injin CNC ko mutummutumi don aiwatar da sarrafa nesa da tsaftacewa, wanda zai iya fahimtar sarrafa kayan aiki da sarrafa kayan aiki, samar da ayyukan layin taro na samfur, da aiki da hankali.

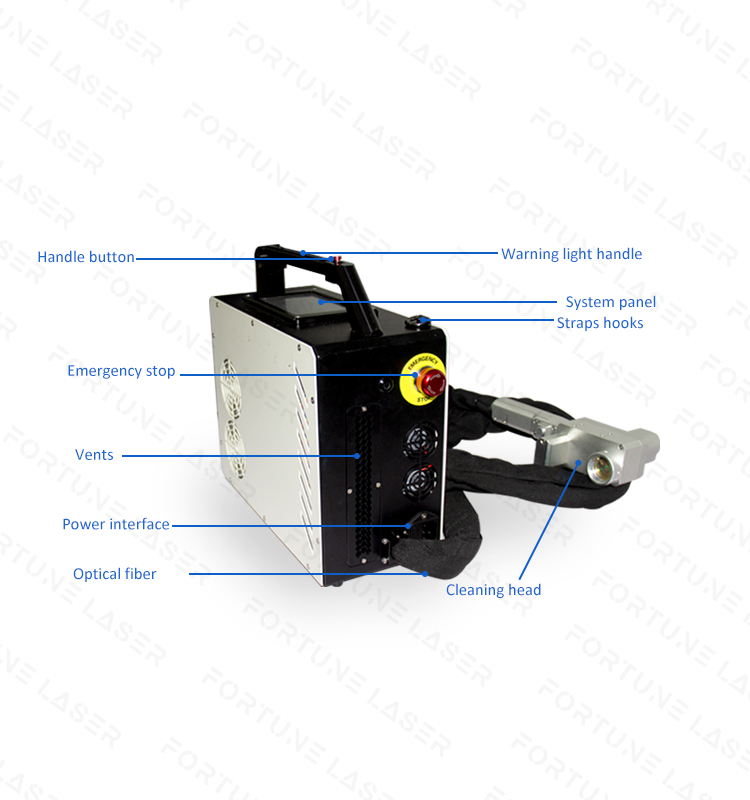

2. Madaidaicin matsayi: yi amfani da watsawar fiber na gani don jagorantar laser don yin sauƙi, da kuma sarrafa wurin haske don motsawa cikin sauri ta hanyar galvanometer da aka gina a ciki, wanda ya dace da sassan da ba su da alaka da wuyar isa ga sassan sassa na musamman, ramuka, da ramukan da ke da wuya a isa ta hanyar tsaftacewa na gargajiya. ƙasa Laser tsaftacewa.

3.Ba lalacewa: tasiri na gajeren lokaci ba zai yi zafi da karfen karfe ba, kuma babu lalacewa ga substrate.

4.Good kwanciyar hankali: Laser pulsed da aka yi amfani da shi a cikin injin tsabtace laser yana da tsawon rayuwar sabis, yawanci har zuwa sa'o'i 100,000, tare da ingantaccen inganci da aminci mai kyau.

5. Ƙananan farashin kulawa: ba a cinye kayan amfani a lokacin amfani da na'ura mai tsaftacewa na laser, kuma farashin aiki yana da ƙasa. A cikin mataki na gaba, kawai ruwan tabarau yana buƙatar tsaftacewa ko maye gurbin akai-akai, kuma farashin kulawa yana da ƙasa, wanda ke kusa da kyauta.

A sama su ne tsaftacewa aikace-aikace da kuma abũbuwan amfãni daga Laser tsaftacewa inji a cikin mota masana'antu. Aikace-aikace na Laser polishing, surface tsaftacewa da shafi kau yana da sauri fadada. Dangane da aikace-aikacen, mitar bugun bugun jini, kuzari da tsayin laser dole ne a zaɓa daidai don tsaftacewa, gogewa da kawar da abin da aka yi niyya. A lokaci guda, kowane nau'i na lalacewa ga kayan tushe dole ne a hana shi.

Idan kuna son ƙarin koyo game da tsaftacewar Laser, ko kuna son siyan injin tsabtace Laser mafi kyau a gare ku, da fatan za a bar saƙo a gidan yanar gizon mu kuma ku yi mana imel kai tsaye!

Lokacin aikawa: Satumba-26-2022