Masu masana'anta koyaushe suna neman yin samfuran da suka fi ƙarfi, masu ɗorewa, kuma mafi aminci, da kuma a cikin sassan kera motoci da na sararin samaniya. A cikin wannan ƙoƙarce-ƙoƙarce, suna yawan haɓakawa da maye gurbin tsarin kayan aiki tare da ƙananan yawa, mafi kyawun zafin jiki da juriya na ƙarfe gami. Wannan yana ba masu masana'anta ingantaccen tushe a kasuwa.

A gaskiya, rabin labarin ke nan.

Wani mahimmin fa'idar dabara mai ƙarfi shine tabbataccen ƙididdigewa game da ƙarfin samfur, dorewa, da amincinsa.

Canja wurin tsofaffin kayan don masu ƙarfi na iya zama farawa mai kyau, amma kuma yana buƙatar ƙarin hanyoyin masana'antu waɗanda ke dogaro da tsabta da ingantaccen tsabtace ƙasa don ƙirƙirar ƙaƙƙarfan tsari. Ƙarfe irin su aluminum gami da kayan haɓakawa irin su carbon fiber polymer composites, sau da yawa ana amfani da su a cikin masana'antar kera motoci da sararin samaniya, suna buƙatar haɗin kai don rage nauyi - lokacin da ake amfani da kayan ɗamara, ana ƙara nauyi zuwa tsarin - kuma don ƙirƙirar haɗin gwiwa mafi aminci.

Dabarun gamawa na gargajiya na aluminum sun haɗa da fashewar yashi, shafa mai ƙarfi, bi da niƙa (amfani da kushin zazzagewa) ko anodizing. Haɗin haɗaɗɗiyar mannewa yana buɗe ƙofar zuwa ƙarin matakai masu sarrafa kansa waɗanda gamawar gargajiya ba su dace ba.

Anodizing ya fi kowa a cikin aikace-aikacen sararin samaniya inda ake amfani da wannan shiri mafi tsada da tsauri don saduwa da ƙayyadaddun bayanai. Bambance-bambancen da ke tattare da fashewar yashi da fasahohin abrasion na hannu yana nuna a sarari cewa ƙarin tsari yana cikin tsari.

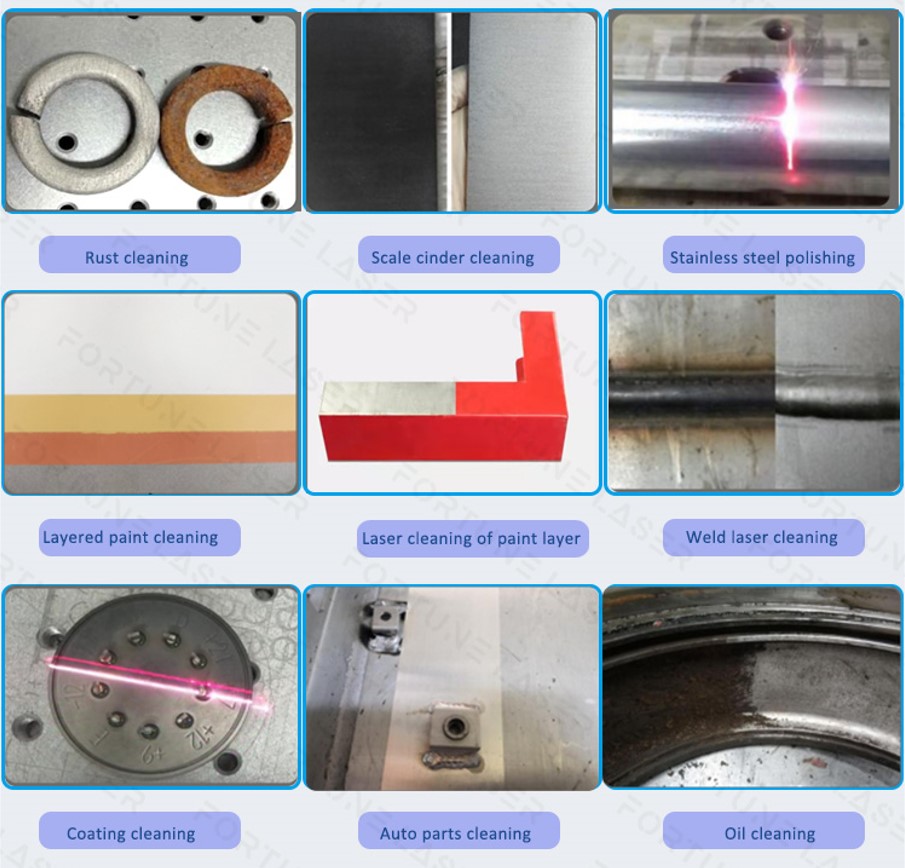

Laser tsaftacewa ko Laser ablation cika wannan tsari rata a matsayin mafi daidai, muhalli abokantaka, atomatik kuma ingantacciyar hanyar zalunta karfe da composite saman domin tsaftacewa. Nau'in gurɓataccen abu da aka samu a saman waɗannan kayan ana samun sauƙin cirewa ta hanyar sarrafa Laser.

Saboda tsaftacewar Laser yana da ƙarfi sosai, yana da mahimmanci don sanin daidai yadda yake shafar saman ku. Bambance-bambancen da ke tsakanin shimfidar da aka yi da kyau da kuma ƙasan da ba a kula da shi ba na iya zama da wahala sosai a tantancewa. Tare da fasahar tabbatar da ƙididdiga masu ƙididdigewa kamar yadda yake da mahimmanci kuma daidai kamar tsarin laser kanta, masana'antun na iya kasancewa da kwarin gwiwa cewa ƙarfen su da abubuwan haɗin gwiwa sun kasance a shirye don haɗin gwiwa.

The wadannan Fortune Laser zai ba ku cikakken gabatarwar ga dalilai na zabar Laser tsaftacewa.

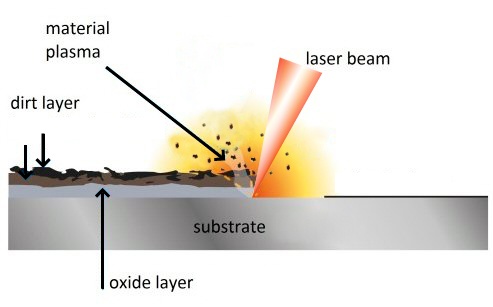

1-Menene Tsabtace Laser?

Maganin Laser ingantaccen fasaha ne na tsabtace zafi wanda ke aiki ta hanyar cire (ablation) ƙananan ɓangarorin saman abu ta hanyar mayar da hankali, sau da yawa bugun jini, katako na Laser. Laser yana haskaka sararin samaniya don cire kwayoyin halitta kuma ana iya amfani dashi don hako ƙananan ƙananan ramuka masu zurfi ta hanyar kayan aiki masu wuyar gaske, samar da fina-finai na bakin ciki ko nanoparticles a saman.

Wannan tsari na tsaftace ƙasa yana da tasiri sosai saboda ikonsa na kai hari ga irin waɗannan ƙananan yadudduka na gurɓatawa da ragowar. Filayen Aluminum sun ƙunshi oxides da mai mai mai da ke da lahani ga haɗaɗɗen mannewa kuma abubuwan da aka haɗa galibi suna riƙe ƙurawar ƙura da sauran gurɓataccen siliki waɗanda ba za su iya samar da haɗin gwiwa mai ƙarfi tare da adhesives ba.

Lokacin da aka shafa manne a saman da ɗaya daga cikin waɗannan ragowar ya kasance zai yi ƙoƙarin yin riko da mai da siliki a saman ƴan yadudduka na kwayoyin halitta. Waɗannan haɗin gwiwar suna da rauni sosai kuma babu makawa za su gaza ko dai yayin gwajin aiki ko yayin amfani da samfurin. Lokacin da haɗin gwiwa ya karye a wurin da saman da m ko shafi suka hadu wannan ana kiransa gazawar tsaka-tsaki. Rashin haɗin kai yayin gwajin sausaya na cinya shine lokacin da hutu ya faru a cikin manne kanta. Wannan yana nuni ne da haɗin gwiwa mai ƙarfi da kuma tsarin da aka haɗa wanda yake da juriya kuma mai dorewa.

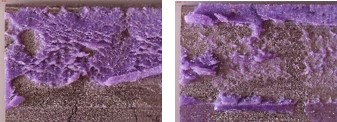

Rashin haɗin kai na waɗannan samfurori masu haɗaka waɗanda aka yi musu magani na laser yana nuna manne a bangarorin biyu na kayan da aka haɗa.

Rashin lalacewar fuska na waɗannan samfurori masu haɗaka waɗanda ba a kula da su ba ya nuna cewa manne kawai ya makale a ɗayan bangarorin kuma gaba ɗaya ya bar ɗayan.

Lokacin da kuka sami gazawar haɗin kai, kuna da haɗin kai tsakanin fuska wanda baya barin komai. Jiyya na saman suna nufin gyaggyara saman don cire gurɓatacce da ƙirƙira ko bayyana saman da zai iya haɗa sinadarai tare da manne don ɗorewa kuma amintaccen haɗin gwiwa.

2- Yadda ake sanin ko saman saman Laser ɗinku yana shirye don mannewa

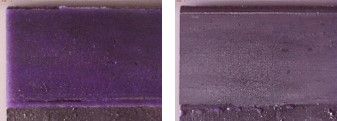

Ma'aunin kusurwa, kamar waɗanda aka ambata a cikin takardar IJAA da aka yi amfani da su don fahimtar lalacewar jiyya akan kari, hanya ce mai kyau ta musamman ta sa ido da kuma tabbatar da matakan tsaftace Laser.

Ma'aunin kusurwa yana kula da sauye-sauyen kwayoyin halitta da ke faruwa a saman da ake yi wa Laser magani. Digon ruwan da aka sanya a saman zai tashi ko faɗuwa daidai dangane da adadin gurɓataccen ƙwayar cuta a saman. Ma'aunin kusurwa alama ce ta mannewa marar karewa kuma tana iya ba da haske da ganuwa cikin yadda aka daidaita ƙarfin jiyya tare da tsaftace bukatun kayan.

Ma'aunin kusurwa yana daidaita da kyau tare da canje-canjen matakan gurɓataccen abu da aka ɗauka ta hanyoyin duban gani. Yawancin ma'aunin ma'auni na gurɓataccen abu a saman ana yin su ne da kayan aiki waɗanda ba su da yuwuwar masana'antun su saya kuma ba za a iya amfani da su akan ainihin sassan da ake kera su ba.

Ana iya yin ma'aunin kusurwar lamba nan da nan kafin da bayan jiyya akan layin samarwa tare damanualkokayan aikin aunawa ta atomatik. Kamar yadda tsaftacewa Laser ya maye gurbin hanyoyin shirye-shiryen da ba a taɓa amfani da su ba saboda buƙatun aiki da kai na babban girma, masana'anta madaidaicin ƙima, ma'aunin kusurwa kuma suna yin gwaje-gwaje masu inganci da ƙarancin inganci kamar dyne tawada da gwajin hutu na ruwa.

Gwajin aikin ƙarfi yana bincika samfurin kayan da ake sarrafa su kawai, ƙara zuwa ƙididdige ƙima kuma baya ba da wata alama ta yadda ake ƙirƙirar haɗin gwiwa mai ƙarfi. Ƙungiyoyin tuntuɓar juna, lokacin da aka yi aiki a ko'ina cikin layin samarwa na iya nuna daidai inda tsarin ke buƙatar tweaking, kuma zai iya ba da haske game da abin da ake buƙatar tweaked da kuma iyakar.

3- Me yasa Amfani da Tsabtace Laser?

An yi kuri'a na babban bincike a kan hanyoyin da Laser surface jiyya inganta mannewa. Misali,wata takarda da aka buga a cikin Journal of Adhesionbinciko yadda ƙarfin haɗin gwiwa ya inganta ta hanyar tsaftacewa na laser sabanin hanyoyin gargajiya.

"Sakamakon gwaji ya nuna cewa preadhesion Laser surface jiyya da muhimmanci inganta karfi ƙarfi na modified-epoxy bonded aluminum samfurori idan aka kwatanta da untreated da anodized substrates. An samu mafi kyaun sakamakon da Laser makamashi na game da 0.2 J / Pulse / cm2 inda guda cinya karfi karfi da aka inganta ta 600-700% idan aka kwatanta da Alchromic acid, idan aka kwatanta da na 40% da alloy. anodizing pretreatment.

Yanayin gazawar ya canza daga mannewa zuwa haɗin kai yayin da adadin bugun laser ya karu yayin jiyya. Lamarin na ƙarshe yana da alaƙa da sauye-sauyen ilimin halittar jiki kamar yadda microscopy na lantarki ya bayyana, da gyare-gyaren sinadarai kamar yadda Auger da infrared spectroscopy suka nuna.

Wani sakamako mai ban sha'awa na ablation na laser shine ikon da yake da shi don ƙirƙirar farfajiyar da ba ta raguwa a tsawon lokaci.

Babban Laserya yi babban aiki duba cikin yadda Laser tsaftacewa hulda da saman a wasu ban mamaki hanyoyi. Maganin Laser na aluminium yana haifar da ƙananan ramuka a cikin saman da ke narkewa kuma kusan lokaci guda yana ƙarfafawa zuwa wani yanki na micro crystalline a saman wanda ya fi juriya fiye da aluminum.

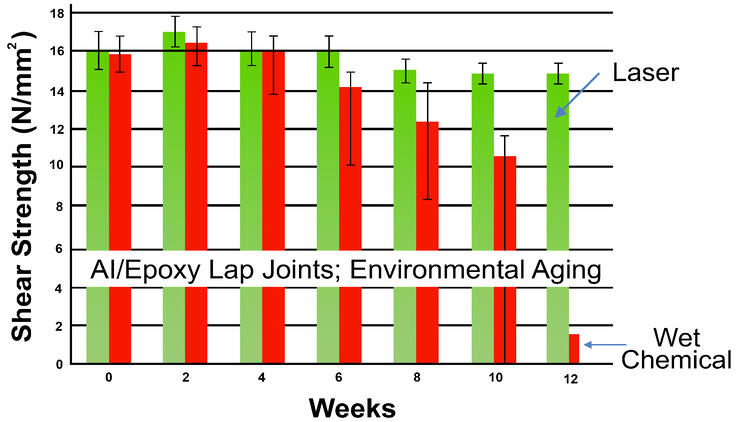

Duban ginshiƙi na ƙasa, yana nuna bambanci tsakanin ƙarfin juzu'i na haɗin gwiwa ta amfani da aluminium wanda aka yi masa maganin laser da aluminum wanda aka yi masa magani. Da shigewar lokaci, yayin da aka fallasa saman ga wani yanayi mai ɗanɗano, ƙarfin saman da aka yi masa magani da sinadarai yana raguwa sosai saboda damshin ya fara lalata saman, yayin da saman da aka yi masa magani na Laser ke riƙe da juriya na lalata bayan makonni na fallasa.

Lokacin aikawa: Agusta-12-2022