Good Wholesale Vendors Affordable Fiber Laser Cutting Machine - High Power Fiber Laser Cutter 6KW~20KW – Fortune

Good Wholesale Vendors Affordable Fiber Laser Cutting Machine - High Power Fiber Laser Cutter 6KW~20KW – Fortune

Good Wholesale Vendors Affordable Fiber Laser Cutting Machine - High Power Fiber Laser Cutter 6KW~20KW – Fortune Detail:

Germany Precitec Cutting Head

Non-inductive perforation, high-speed operation, auto focus, flexible cutting different materials and thickness of plates. Small taper, bright surface, smooth cutting section without burrs. The internal structure of the laser head is completely sealed, which can prevent the optical part from being polluted by dust, with that, it is reliable and stable.

IPG Laser Source

The most famous laser source manufacturer in the world. Powerful cutting ability, the cutting thickness of sheet metal can reach 80mm. Excellent beam quality at high power. Higher electro-optical conversion efficiency, lower power consumption, and low maintenance cost.

Exchange Platform

● Faster and more stable.

● Improve processing accuracy and safety.

● Increase productivity.

Double motor double chain automatic exchange platform, the platform is composed of a welded frame, with a support grid on which the workpiece is supported, and the worktable can bear a load of up to 1000KG; there are universal balls around the worktable, driven by Yaskawa servo motor, stable exchange speed within 8-15s, effectively preventing deviation and collision.

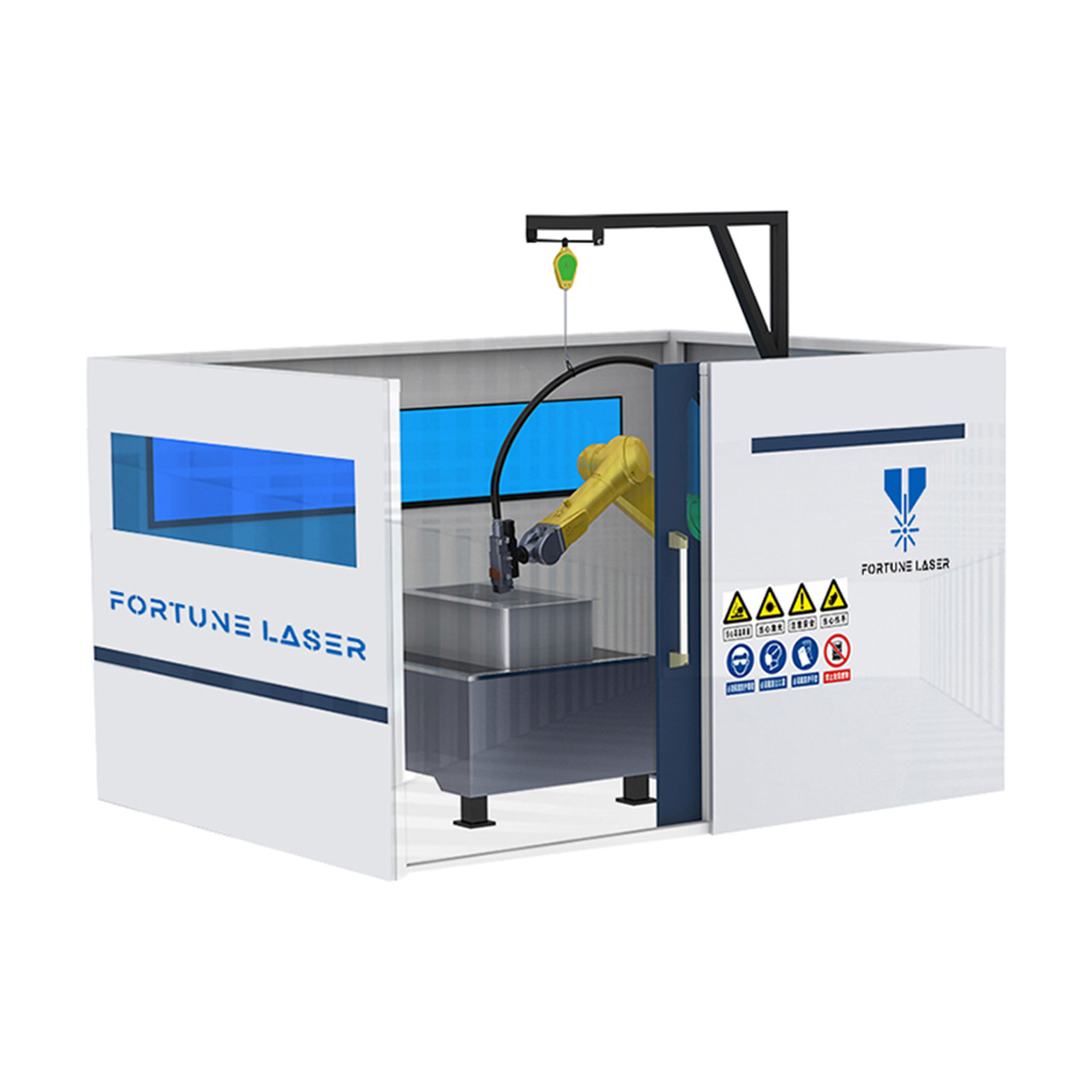

Machine Characters

● Hollow plate welded heat dissipation bed. The special bed for ultra-high power laser cutting machine is made of high-strength steel. The cutting area is hollow to prevent the machine from overheating and deforming. Provide strong guarantee for customers to realize long-term batch cutting of medium and thick plates.

● Full protection cover. The front and back of the protective cover are equipped with built-in cameras and use the intelligent central control system to monitor the operation. The European CE standard OD4+ level protective glass observation window, thickened sheet metal protective cover, safe production.

● Germany Precitec auto focus laser head: Lightweight design, fast acceleration, the monitoring data can be read on the mobile terminal or CNC system, auto focus is simple, fast and more precise. Non-inductive perforation, high-speed operation, flexible cutting different materials and thickness of plates.

● Fast swap: Equipped with a six-sided steel track, the pulley and the track are inlaid closely, and the built-in pulley runs smoothly. The fastest exchange speed can reach to 10s for a complete exchange. Save time and cost for your projects.

● The operation is simple and easy to use: Use powerful control system specifically for laser cutting machine. Comprehensive diagnosis function to find faults quickly. The corresponding process database can be set according to different materials and thicknesses, efficient automatic nesting function. Support contour inspection and complex graphics repair functions. Automatically optimize the cutting path. Follow the intelligent lifting and leapfrogging function to make the machine more flexible and accelerate faster.

● Top brand fiber laser: Use stable and reliable power top brand laser, performance guaranteed;

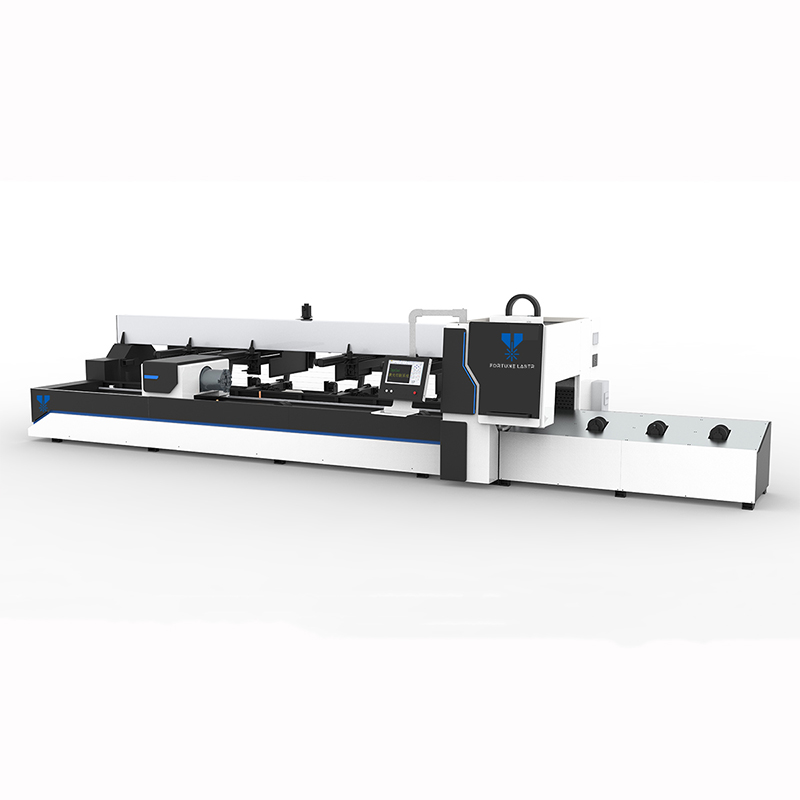

Machine Parameters

|

Model |

FL-U3015/FL-U4020 |

FL-U6020/6025 |

FL-U8020/8025 |

|

Laser Source Power |

6kW-20kW |

6kW-20kW |

6kW-20kW |

|

Working Area (L*W) |

3000*1500mm, 4000*2000mm |

6000*2000mm/2500mm |

8000*2000mm/2500mm |

|

X/Y Axis Position Accuracy |

±0.05mm/1000mm |

±0.05mm/1000mm |

±0.05mm/1000mm |

|

X/Y Axis Repeat Position Accuracy |

±0.03mm |

±0.03mm |

±0.03mm |

|

Max Moving Speed |

120M/min |

120M/min |

120M/min |

|

Max Acceleration |

1.2g |

1.2g |

1.2g |

|

Machine Dimension (L*W*H) |

8502*2600*2100mm |

14000*3500*2200mm |

16000*3500*2200mm |

|

Max Loading Weight |

600kg |

3200kg |

3200kg |

|

Machine Weight |

2000kg |

10000kg |

12000kg |

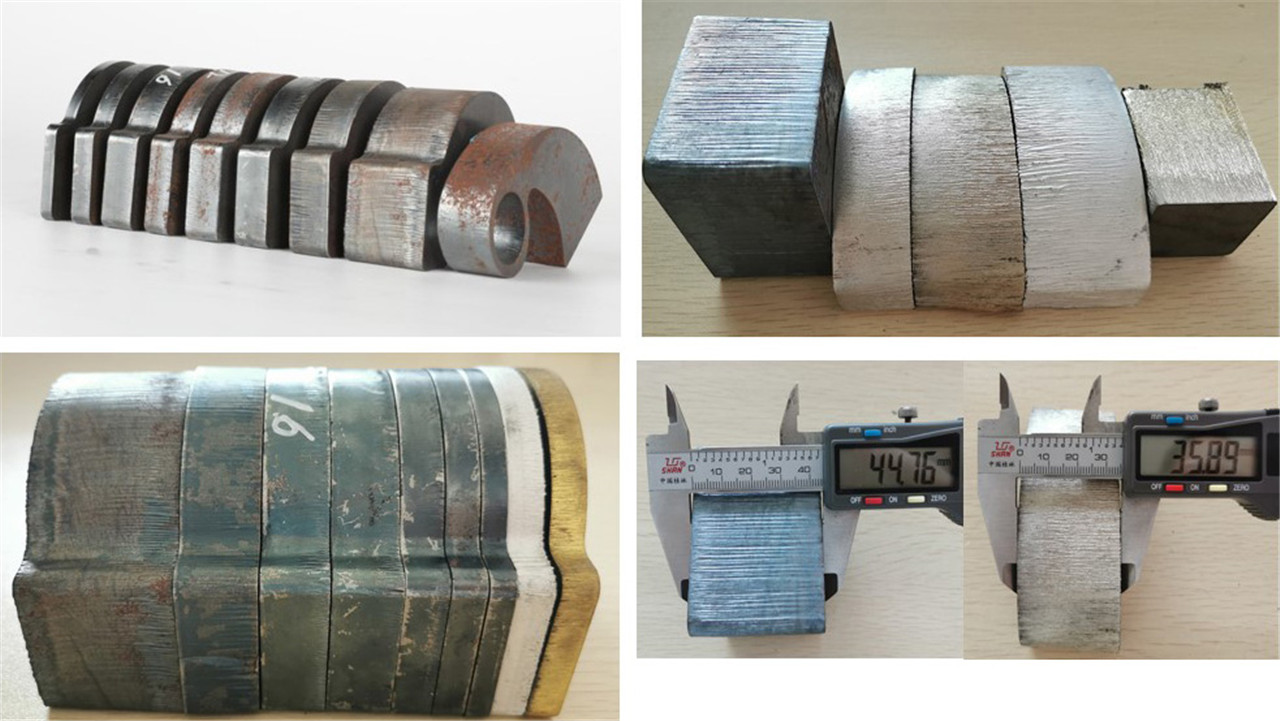

Samples Display

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for Good Wholesale Vendors Affordable Fiber Laser Cutting Machine - High Power Fiber Laser Cutter 6KW~20KW – Fortune , The product will supply to all over the world, such as: Pretoria, Jamaica, Thailand, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.