Fortune Laser Pulses 500W Water Cooling Laser Cleaning Machine

Fortune Laser Pulses 500W Water Cooling Laser Cleaning Machine

Equipment Introduction

The Fortunelaser FL-HC500 pulse laser cleaning system can be used to clean various metal substrates, such as titanium alloy, aluminum alloy, high temperature alloy, stainless steel, carbon steel and other parts surface oxide layer, coating, oil, rust, coating and other cleaning. Laser cleaning works within the window parameters to remove contaminants without damaging the substrate. The equipment is designed and manufactured by Fortune Laser owns and precisely masters the world-class high-end laser cleaning technology, which has been used in aviation, aerospace, shipbuilding, automobile, electronic industry and other fields.

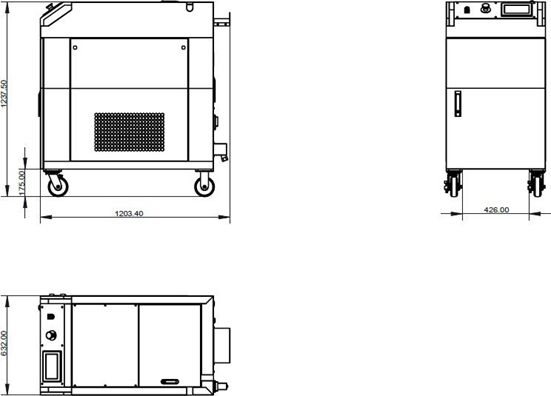

The following picture shows the appearance of the 500W laser cleaning system. The system integrates laser generator, laser head, water cooling system and control system. It is lightweight and flexible, and optical fiber transmission. The equipment is easy to use and operate. Start the power supply, take out the laser head from the storage cabinet, and select the appropriate cleaning mode to achieve cleaning. If you need a low-power cleaning machine, you can check our link

500W Laser Cleaning Machine Main Features:

●The laser source adopts a high-efficiency and highly integrated nanosecond pulsed fiber laser. The average output power of the laser is 500 watts, and the maximum instantaneous peak power can reach megawatts.

●The use of nanosecond short pulse light source can reduce the heat generation of cleaning parts and basically realize "cold treatment".

●The cleaning mechanism is selective absorption, ensuring effective removal of contaminants without damaging or modifying the substrate under operating conditions of window 4 parameters.

●The equipment adopts optical fiber conduction, which is light and flexible. The laser head equipped with the equipment can be installed on the mechanical arm to realize efficient automatic cleaning.

●The laser head uses a high-speed galvanometer to convert the point light source into a line light source to achieve more efficient cleaning.

●High-quality parts and accessories, all parts are guaranteed by international famous brands;

●Green, environmentally friendly and pollution-free, globally recognized as the greenest and most environmentally friendly industrial cleaning method;

●The world's top process support, comprehensive process technical support from the returnee doctor and master tea

Fortune Laser Mini Laser Cleaning Machine Technical Parameters

|

Model |

FL-HC500 |

||

|

Laser Type |

Pulse |

||

|

Laser Power |

500W |

||

|

Cooling Way |

Water Cooling |

||

|

Working temperature |

10-40℃ |

||

|

Storage temperature |

-20-60℃ |

||

Description Of The Main Components Of The Overall System:

1.Laser Source:

The laser source adopts high-efficiency and high-integration Raycus long-life nanosecond pulsed fiber laser. The laser can operate continuously for 24 hours and has a service life of ≥50,000 hours.

Laser source technical parameters:

|

Maximum average power |

500W |

|

Power adjustment range |

10-100% |

|

Laser output center wavelength |

1064nm |

|

Maximum single pulse energy |

25mJ |

|

Pulse width |

130-160ns (not adjustable) |

|

Laser pulse frequency |

20-50kHz |

|

Power stability |

≤ 5% |

|

Conductive fiber length |

10m |

|

Minimum bending radius |

30cm |

|

Laser safety classification |

Class 4 |

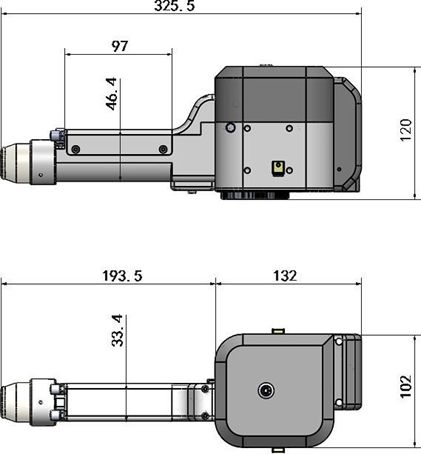

2.Laser Cleaning Head

The internal structure of the laser head mainly includes the optical path system and the circuit system. The laser head can be installed on the manipulator to realize efficient automatic cleaning. At the same time, the laser head contains a visible indicator light indicating the laser focus point, which is convenient for pre-identifying the specific position of the workpiece and manipulator programming. The optical fiber guides the laser beam into the laser head through the optical fiber connector, which is reflected by the galvanometer and focused on the working point by the focusing field lens to realize laser processing.

Handheld/Robot Arm Dual-purpose 2D Laser Head

The technical parameters of the laser head are shown in the following table:

|

Parameter Name |

Parameters Table |

|

Laser Head Type |

2D Laser Head |

|

Working Focal Length |

F150 (F200, F250, F300 Optional) |

|

Scan Line Width |

100mm×100mm Adjustable |

|

Laser Head Weight |

≤ 2.5kg |

|

Laser Safety Classification |

Level 4 |

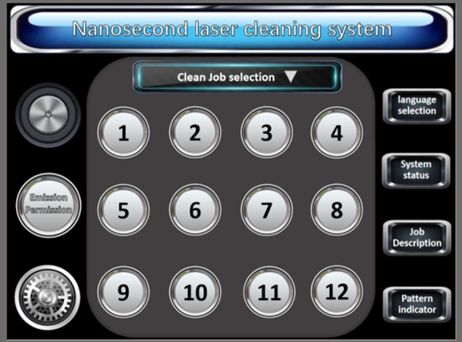

3. Control System

The laser cleaning system software can control settings such as laser energy, pulse frequency, laser scanning width, scanning speed, and scanning graphics. The host is controlled by touch screen, with Chinese interface and anti-reflection design of sunlight screen. The operation interface is simple and the controllability is good. The software of the laser cleaning system has a dual-user level interface. Advanced users can adjust all parameters of laser processing. Users can choose different processing graphics, and can pre-store the set laser parameters and scanning graphics in the system, and ordinary users can directly call them.

In the normal user mode, the operator only needs to turn on/off the system, select one of several modes for the application, and click Prepare to perform the cleaning operation. When an abnormal alarm occurs on the equipment, ordinary operators need to report to the maintenance engineer designated by the equipment, and the maintenance engineer logs in to the advanced user mode to perform equipment testing.

System user operation panel

How much does a laser cleaning machine cost?

The price of a laser cleaning machine is of course different from the pricing of traditional cleaning methods. Compared with the attributes of consumables required for traditional cleaning, the one-time investment of a laser cleaning machine in the early stage is high, and in the post-cleaning process, there will be no additional costs. Consumables costs. As a laser cleaning equipment, its price mainly depends on different configurations. For example, if a laser with higher power is used, the price will definitely be higher.

The prices of the same type of laser cleaning machines in the low-power segment are often slightly different, not to mention those in the ultra-high-power segment: composite laser cleaning of more than 8000W used to remove paint on large equipment such as aerospace, ship high-speed rail, etc. Machines are generally redesigned and manufactured according to the customer's equipment site, use environment and other conditions, and the price is often determined only after on-the-spot measurement.

It can be said that the laser cleaning machines purchased by different customers will not be exactly the same. That's why it's not exactly priced. Even so, the cleaning equipment of the same power segment still has a general price range in the market. For example, the 100-300W laser cleaning machine, the current market price is generally between $20,000-60,000; the price of the 1000W cleaning machine is Between $150,000-180,000. It fluctuates according to the technical process and professional level of each manufacturer.

What Is The Difference Between Water-cooling And Air-cooling Pulse Laser Cleaning Machines?

Cooling the laser machine is important in the operation of the equipment.

The Laser beam comes from a hand-held cleaning head, it comprises a triggered housing for containing the optic components in a shell or gun housing. The hand-held cleaning head can be used to safely direct laser energy to a surface to be cleaned; the laser beam ablates from the surface coatings, corrosion, and the like without harming the substrate.

●The Air-cooled Laser Cleaning Resonator and portable Hand-Held Cleaning Head are cooled by the environmental air with fans and or cooling fins.

●The Water-cooled Laser Cleaner is cooled by a chiller or condenser, via tubes to the laser resonator and the cleaning head.

Difference Air Cooled vs Water Cooled Lasers

●Air-cooled Lasers:

Smaller operations

Compact and portable

Less cost but higher maintenance

Less cooling protection

●Water-cooled Lasers:

Industrial medium and large operations.

High energy efficiency.

Near constant performance achievable, independently of the ambient temperature.

Higher initial cost

Lower maintenance

IP62 Ingress Protection

Why Pulse Laser Cleaning Machines Won't Hurt Substrates?

With our programmable Pulsed Lasers, combining both hardware and software configurations, enable absorption of the dirt (rust, oil, paint, grease, adhesives, separators) where the laser ablation occurs, i.e. removal of impurities, but controls enough energy to not damage the substrate (steel, stainless steel, aluminium, metals, copper, stone, sandstone, granite, marble…), therefore it is especially suitable for cleaning moulds, tools, car parts, machines and also restoration in general.

Video

Laser cleaning machine cleaning effect: