Fortune Laser Mini 1000W/1500W/2000W 3 In 1 Fiber Handheld Laser Welding Machine

Fortune Laser Mini 1000W/1500W/2000W 3 In 1 Fiber Handheld Laser Welding Machine

At the same time, this small hand-held laser welding machine supports cutting and welding at the same time and standard wire distribution machine, which can reduce the clearance requirements of parts and further improve the welding quality. It can also be used in conjunction with a collaborative robot to fix the welding torch on the collaborative robot, reducing the operator's labor intensity and improving the welding quality of the weld.

1000W 1500w 2000w 3000W Mini Laser Welding Machine Advantage

All-in-one chassis design is convenient

Fortunelaser hand-held fiber laser welding machine adopts the design of an integrated cabinet, which integrates the laser, chiller, software control, etc., and has the advantages of small footprint, convenient movement, and strong functionality.

Instead of "fixed optical path", the operation is more convenient.

Now hand-held welding, using a hand-held welding gun to replace the fixed optical path, the operation is more convenient, breaking through the limitations of the workbench, to meet the welding of various angles and positions. In addition, infrared positioning is used for more precise positioning and calibration of the welding position to ensure more beautiful welds.

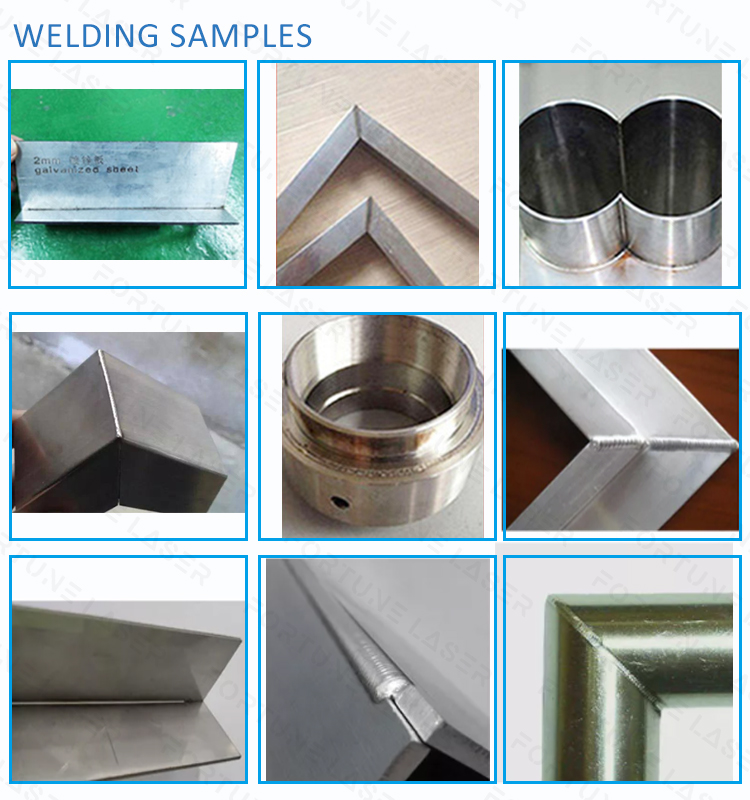

Small thermal deformation, smooth and beautiful weld

We can see that the welding seam of the optical fiber hand-held laser welding machine is smooth and beautiful, the welding workpiece has no deformation, no welding scar, and the welding is firm, reducing the subsequent grinding process, saving time and cost. Traditional welding is difficult to achieve the beauty of welding of complex workpieces, while hand-held welding can achieve right angles, rounded corners and more welding methods, making welding easier.

The welding depth is large and the welding is firm

The hand-held fiber laser welding machine is mainly used for laser welding of long-distance and large workpieces. The heat-affected area during welding is small, which will not cause work deformation, blackening, and traces on the back. The welding depth is large, the welding is firm, and the melting is sufficient.

One machine supports three functions of welding, cutting and cleaning

The conversion of 3 functions can be realized only by the laser head.

Fortune Laser Mini Laser Welding Machine Technical Parameters

|

Model |

FL-HW1000M |

FL-HW1500M |

FL-HW2000M |

|

Laser Power |

1000W |

1500W |

2000W |

|

Cooling Way |

Water Cooling |

Water Cooling |

Water Cooling |

|

Laser Wavelength |

1080nm |

1080nm |

1080nm |

|

Way of Working |

Continuous/ Modulation |

||

|

Fiber Length |

Standard 10m, the longest customized length 15m |

||

|

Dimension |

100*68*45cm |

||

|

Weight |

165kg |

||

|

Options |

Portable |

||

|

Speed range of welder |

0-120mm/s |

||

|

Temperature |

15-35℃ |

||

|

Operating Voltage |

AV 220V |

||

|

Focal Spot Diameter |

0.5mm |

||

|

Welding thickness |

0.5-5mm |

||

Features

l Basic features: self-developed three-in-one control system, flexible switching of welding, cleaning, and cutting, multiple safety alarms, simple and flexible operation.

l More stable: All parameters are visible, real-time monitoring of the status of the whole machine, avoiding problems in advance, facilitating troubleshooting and solving problems, and ensuring stable operation of the system.

l Process: Process parameters can be set, and various process effects can be tried flexibly.

l Stable parameters and high repeatability: The determined nozzle air pressure and lens state, as long as the laser power is stable, the process parameters must be repeatable, which greatly improves efficiency.

|

Supply voltage (V) |

220V±10% AC 50/60Hz |

|

Place the environment |

Flat, no vibration and shock |

|

Working environmenttemperature (℃) |

10~40 |

|

Working environment humidity(%) |

<70 |

|

Cooling method |

Water cooling |

|

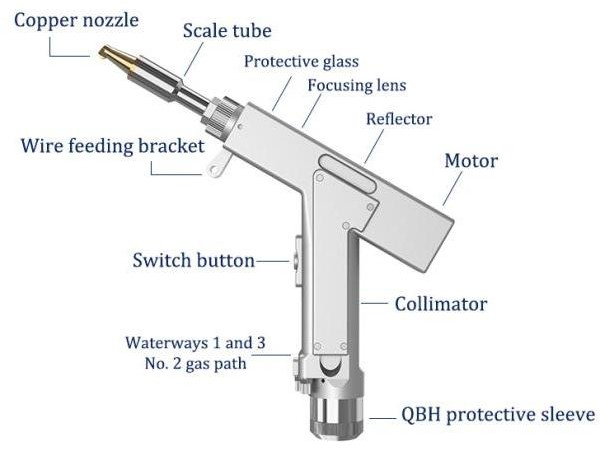

Collimation |

D20*5/F60 |

|

Focus (handheld welding mode) |

D20*4.5/F150 |

|

Focus (cleaning mode) |

D20*4.5/F400 |

|

Reflection |

30*14 T2 |

|

Protective lens specifications |

18*2 |

|

Maximum supported air pressure |

10Bar |

|

Focus vertical adjustment range |

±10mm |

|

Spot adjustment range (handheldwelding mode) |

0~6mm |

|

Spot adjustment range (cleaningmode) |

0~50mm |