1.High-precision welding: Robot laser welding machines can achieve high-precision welding, and the welding quality is stable and reliable. It is also widely used in the field of production and processing.

2.High efficiency and energy saving: Since the robot laser welding machine uses very little energy to complete the welding work, it also has great advantages in terms of energy saving. It is also very easy to maintain when working continuously for a long time.

3.High-speed production: Robot laser welding machines can complete a large number of welding operations in a short period of time, and have great advantages in terms of speed. And since the welding process is done by robots, the welding efficiency is higher.

Main Technical Parameters of the robot laser welding machine

1. Robot

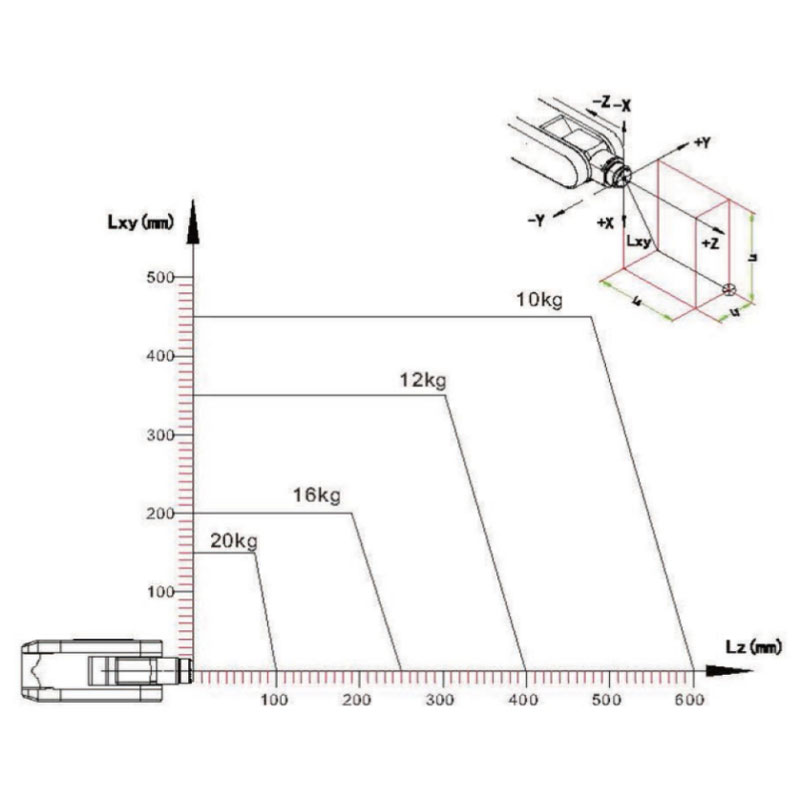

Robot load graph:

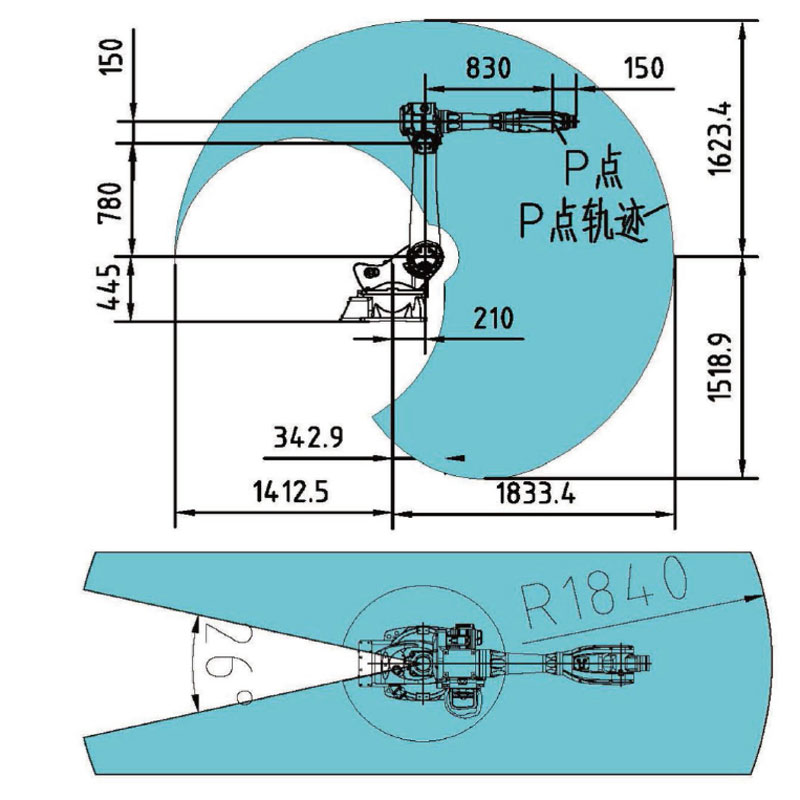

Dimensions and action range Unit: mm

P point action range

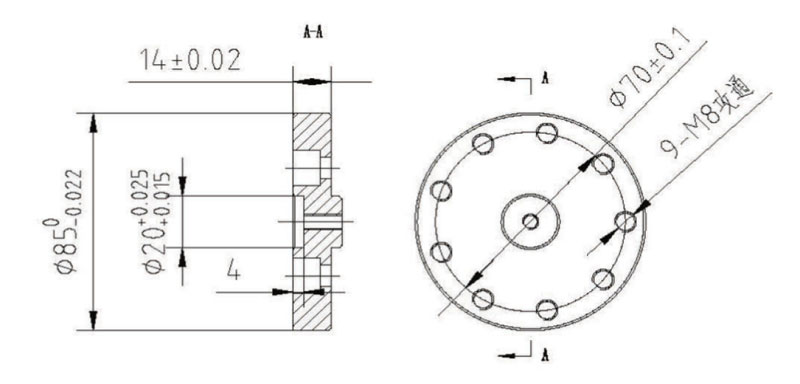

End flange mounting dimensions.

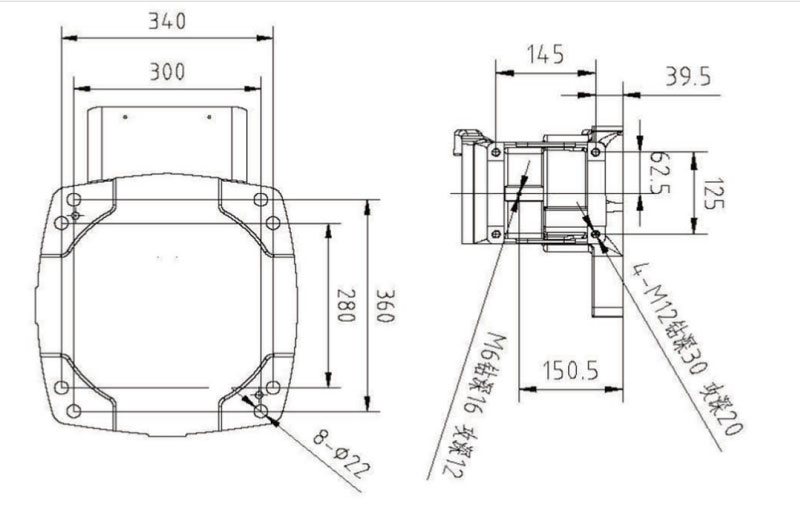

Base installation dimensions Four-axis installation size