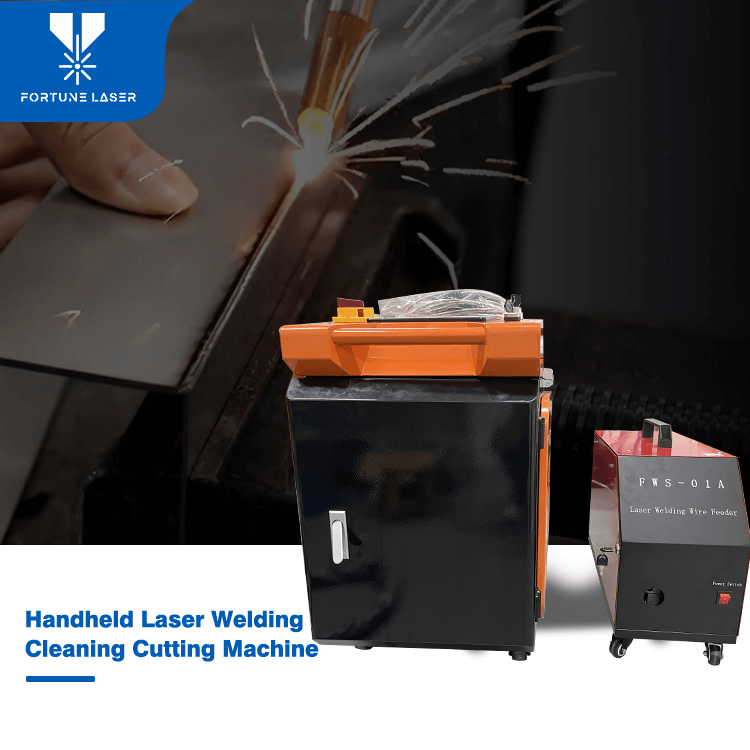

Fortune Laser Hot Sale 1000W-3000W 3 In 1 Laser Systsem Handheld Laser Welding Cleaning Cutting Machine

Fortune Laser Hot Sale 1000W-3000W 3 In 1 Laser Systsem Handheld Laser Welding Cleaning Cutting Machine

Features of Fortune Laser Welding Machine

1. The integrated structure design of the whole machine, the equipment occupies a small space, and is equipped with large universal casters, which is easy to carry and carry;

2. A variety of welding contact tips are equipped as standard to meet a variety of welding needs, and can achieve high-precision welding. The weld seam is small, beautiful and firm;

3. Professional laser welding software, powerful and easy to learn and use, general workers can be employed after training, no need for professional welders;

4. The equipment has strong expandability, and can be connected to wire feeders, robots, etc., and can be equipped with single pendulum or double pendulum welding joints;

5. The electric control area is equipped with a cooling fan as standard, which can effectively improve the welding stability in high temperature environment (optional cabinet air conditioner);

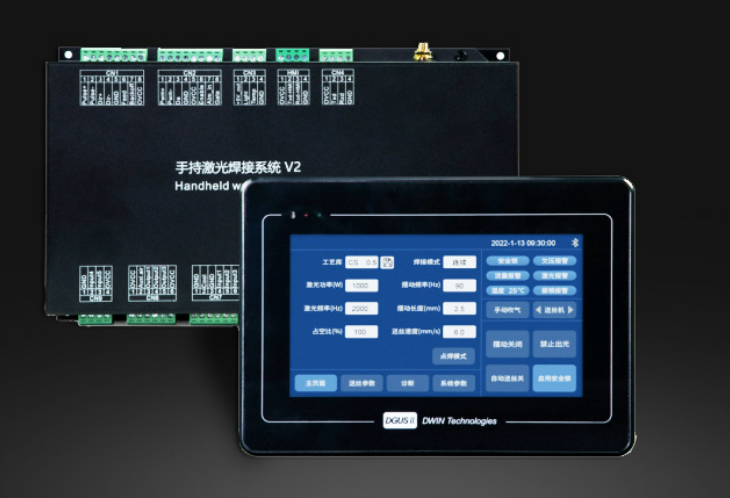

6. Visual instrument and water injection port can be observed at any time during use, and the touch screen control panel is used at the same time to modify the process parameters more intuitively and conveniently;

7. The system can store a variety of different process parameters, which can be switched at any time through the touch screen according to the processing requirements, which significantly reduces the parameter debugging time.

Do you also have these troubles?

1.The Weld is not safe

2.The weld is not beautiful

3.High labor cost

Our machines can give you the perfect solution.

Powerful performance, more intelligent operation, independent warning, self-protection and quick troubleshooting

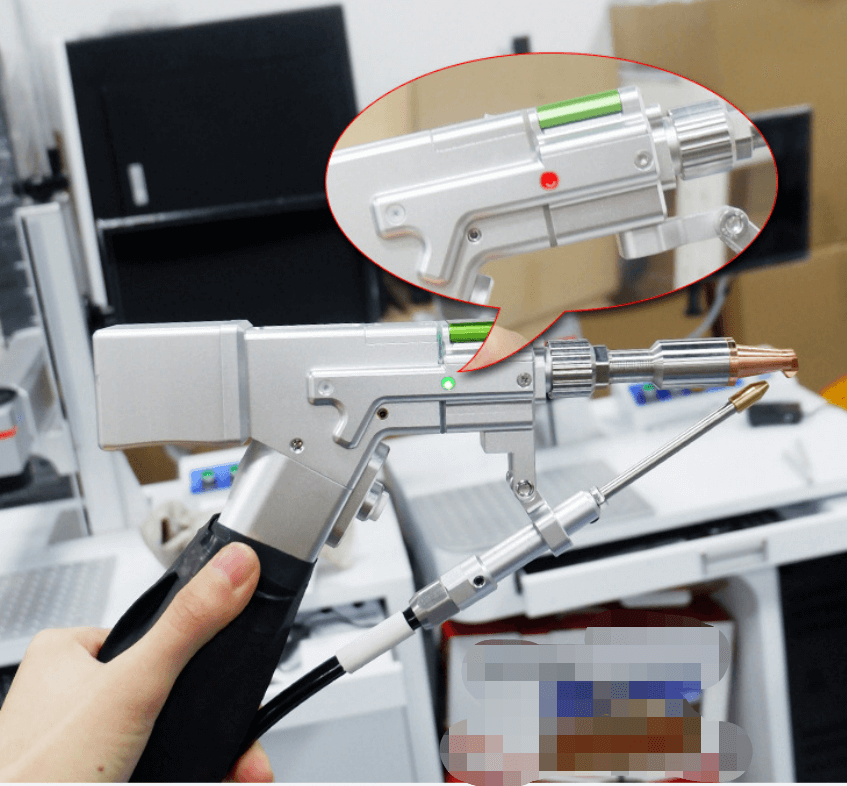

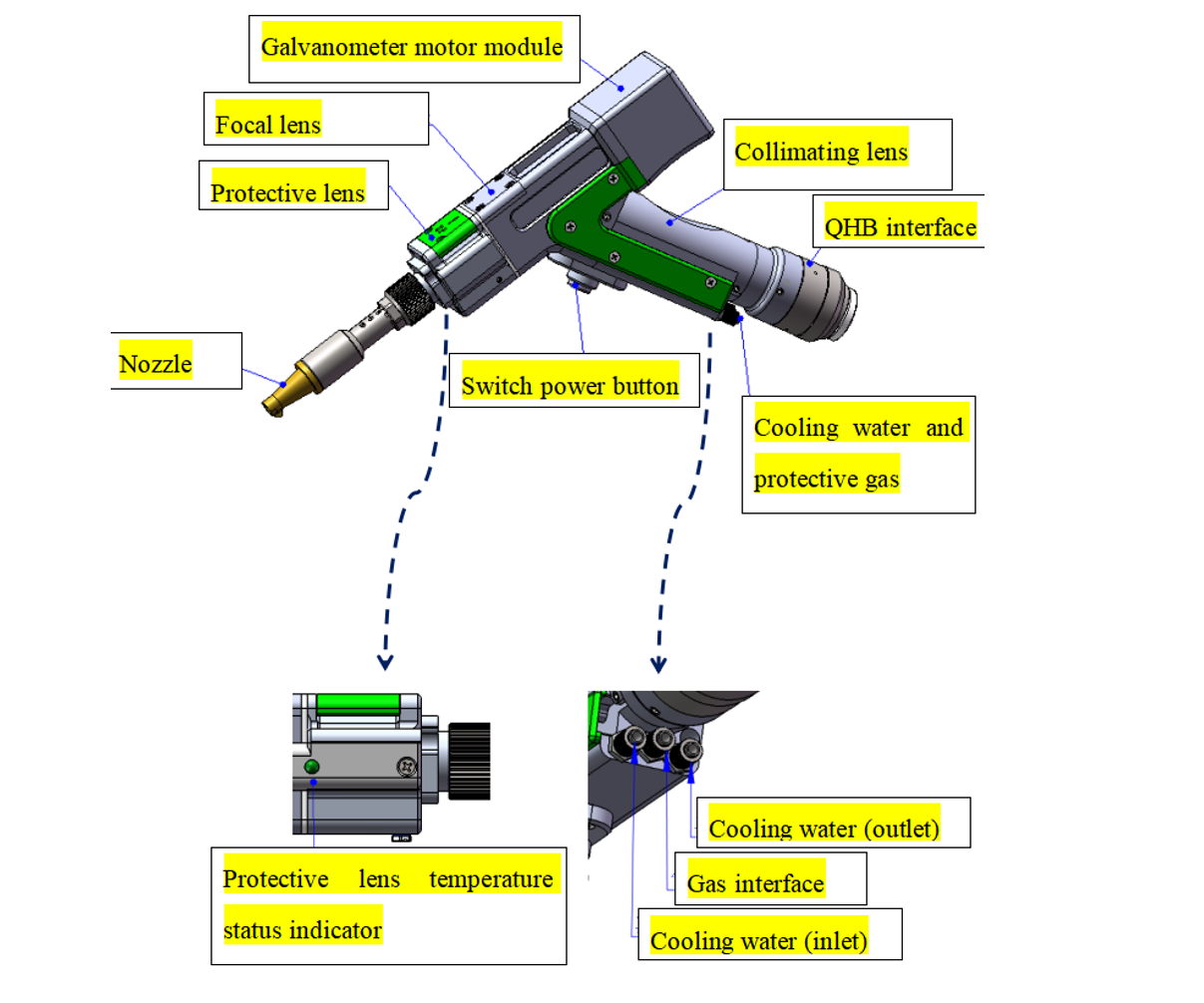

Intelligent detection, monitoring and protection device: lens temperature setting value, when the lens temperature exceeds the setting value, an alarm will appear on the main page to remind the side of the handheld laser head and the indicator light will be red at the same time

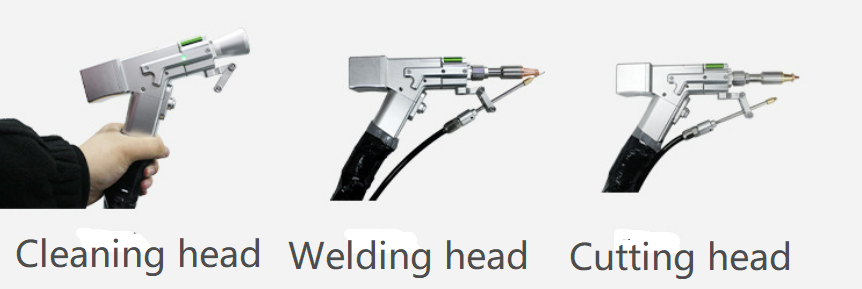

Simple operation, three functions can be switched at any time

Fortune Laser Economy Laser Welding Machine Technical Parameters

Welding penetration parameters

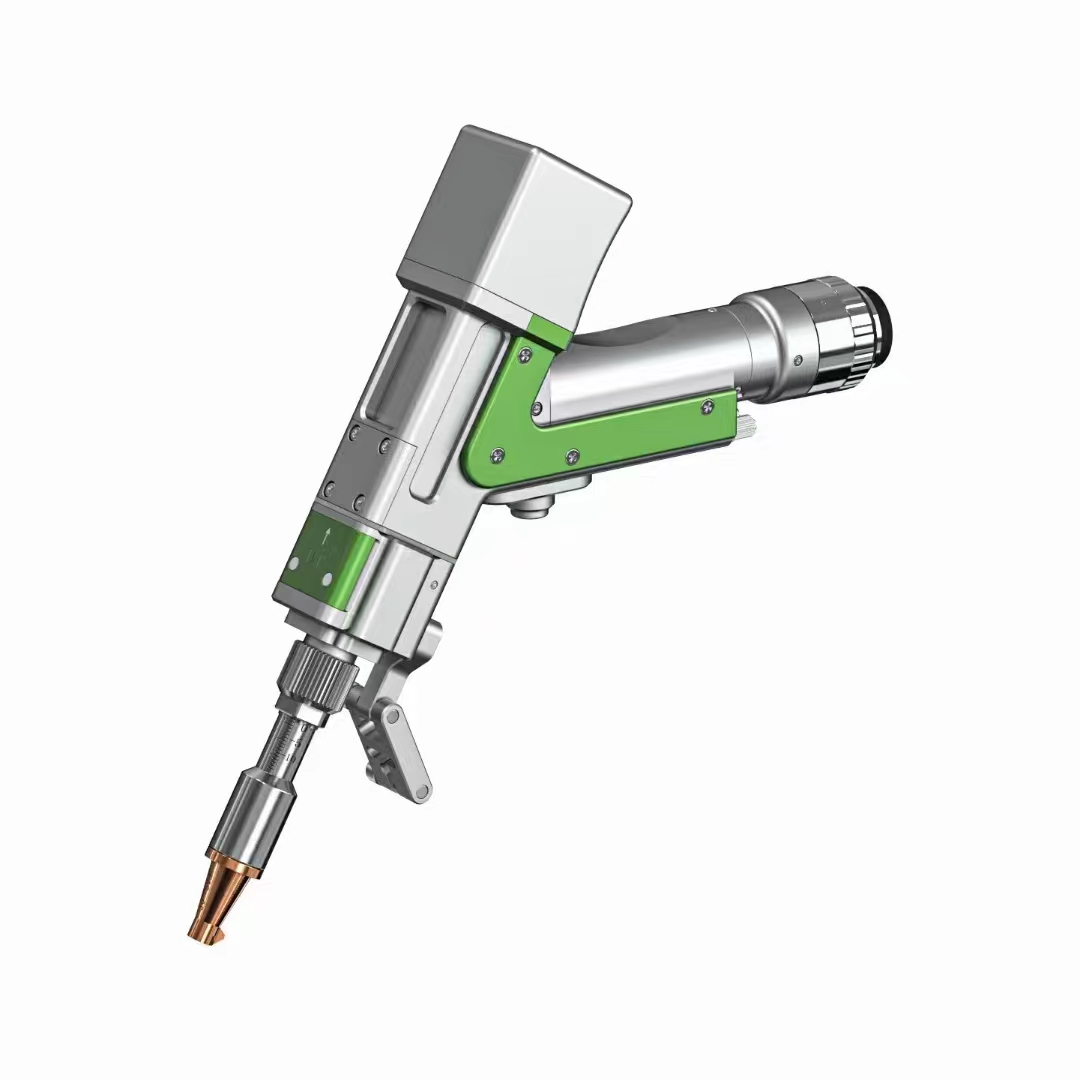

About Fortune Laser RelFar 3 In 1 Laser Head Features

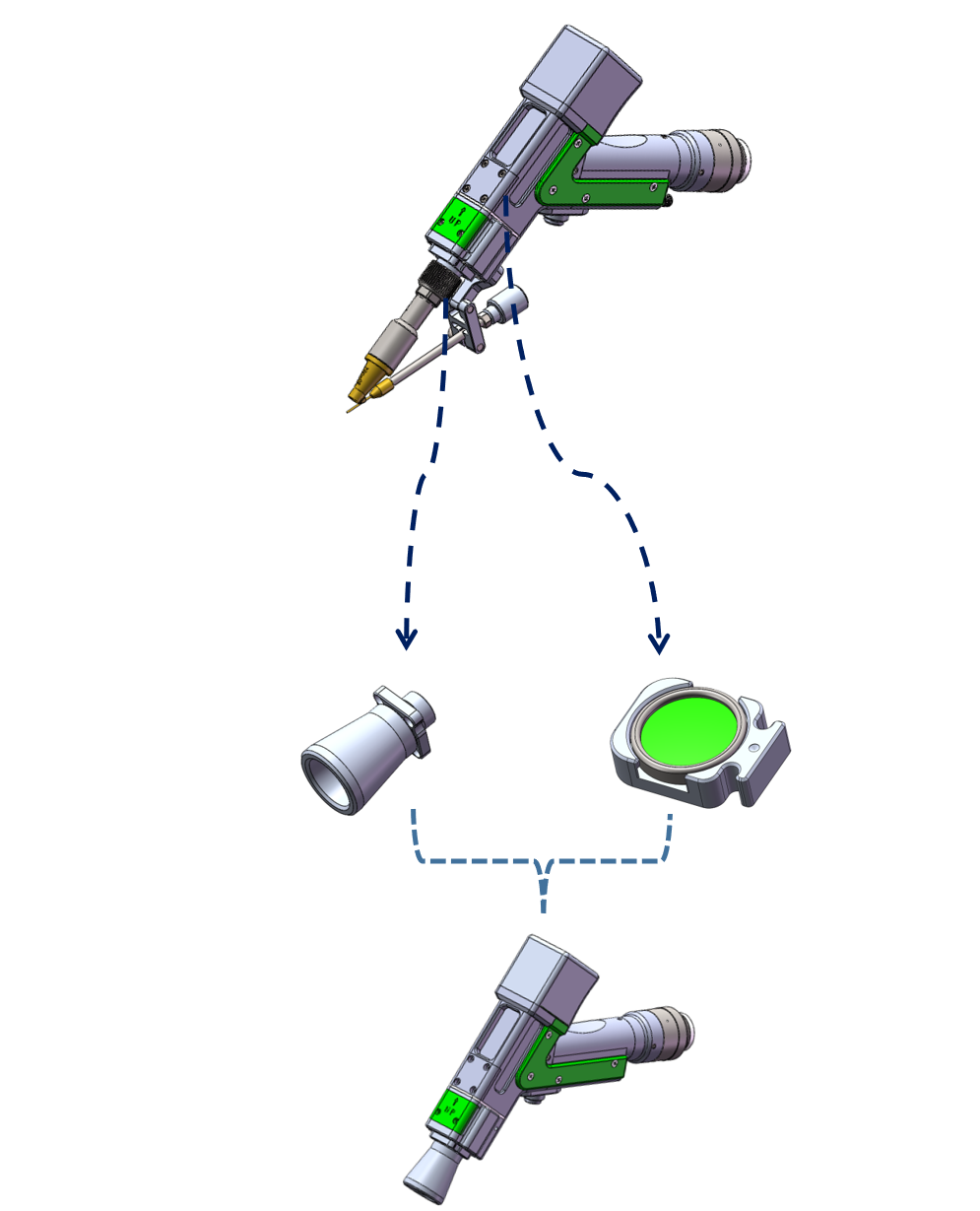

Laser head details

Laser head parameter

Wire Feeder Details