Fortune Laser Automatic 1000W/1500W/2000W Fiber Laser Continuous platform Welding Machine

Fortune Laser Automatic 1000W/1500W/2000W Fiber Laser Continuous platform Welding Machine

Basic Principles of Laser Machine

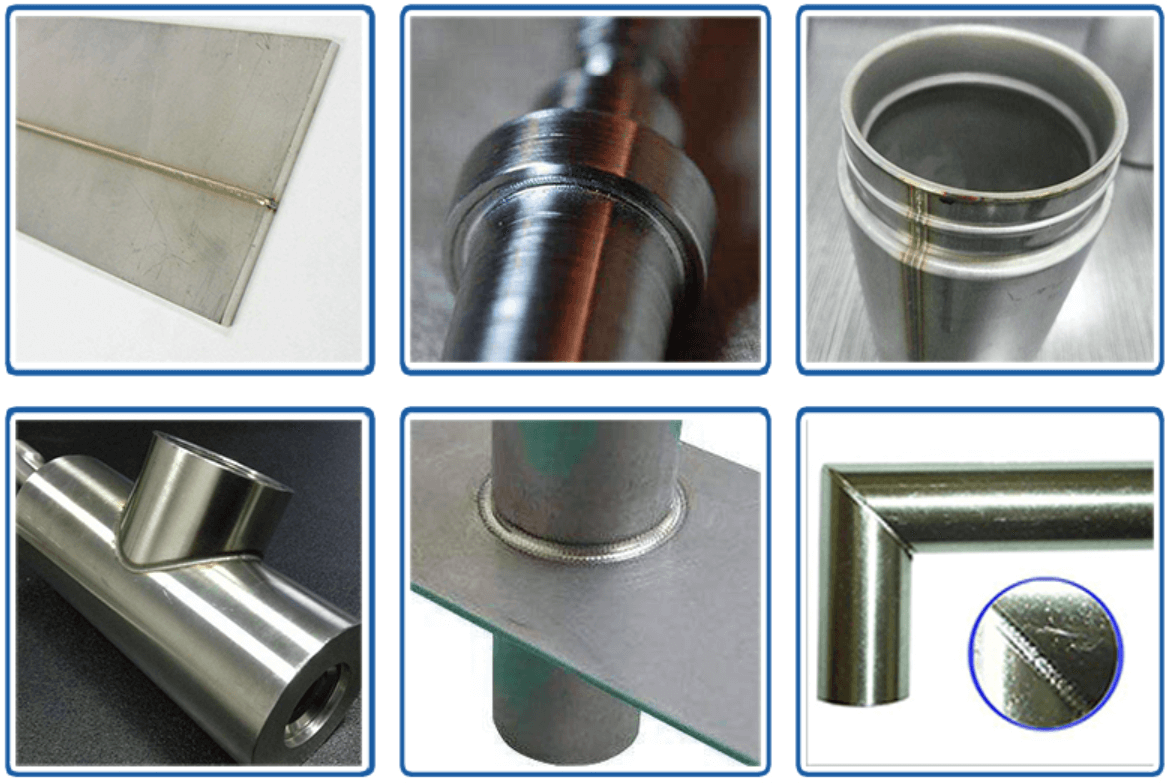

The continuous fiber laser welding machine is a new type of welding method. It is generally composed of a "welding host" and a "welding workbench". The laser beam is coupled to the optical fiber. After long-distance transmission, it is processed into parallel light focusing. Continuous welding is carried out on the workpiece. Due to the continuity of the light, the welding effect is stronger and the weld seam is more fine and beautiful. According to the different needs of different industries, the laser welding equipment can match the shape and workbench according to the production site and realize automatic operation, which can fully meet the needs of users in different industries.

Most of the continuous fiber laser welding machines use high-power lasers with a power of more than 500 watts. Generally, such lasers should be used for plates over 1mm. Its welding machine is deep penetration welding based on the small hole effect, with a large depth-to-width ratio, which can reach more than 5:1, fast welding speed, and small thermal deformation.

1000W 1500w 2000w Continuous Laser Welding Machine characteristic

Fortune Laser Continuous Laser Welding Machine Technical Parameters

Accessories

1. Laser source

2. Fiber Laser cable

3. QBH laser welding head

4. 1.5P chiller

5. PC and welding system

6. 500*300*300 Linear Rail Servo Electric Translation Stage

7. 3600 four-axis control system

8. CCD camera system

9. Mainframe cabine