Fortune Laser 3W 5W UV Laser Marking Machine

Fortune Laser 3W 5W UV Laser Marking Machine

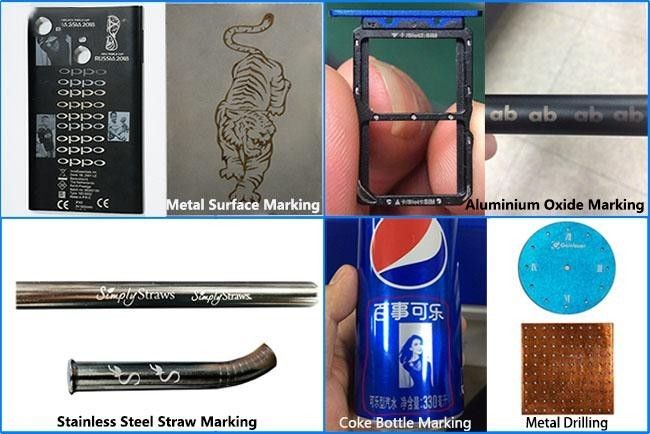

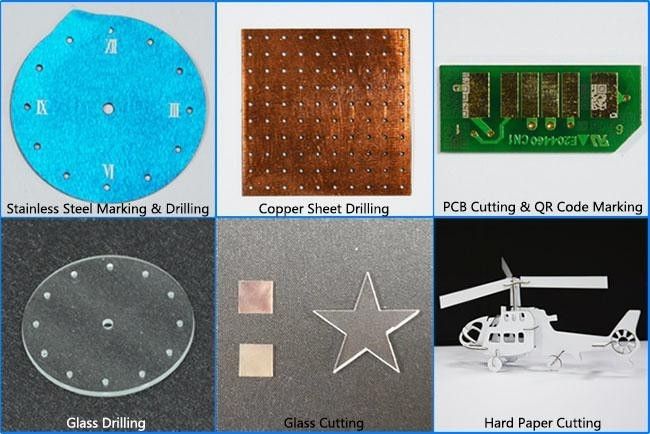

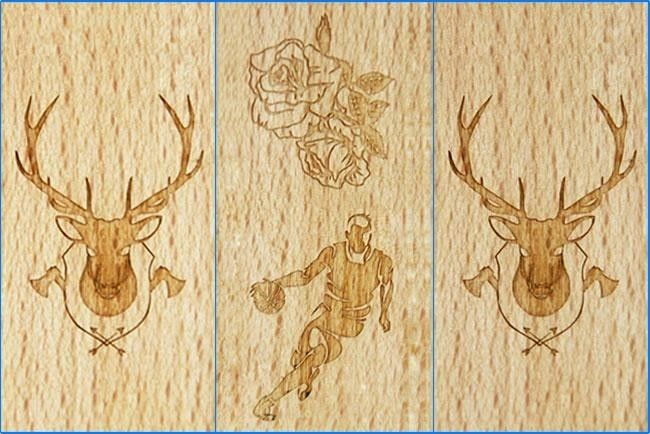

Basic Principles of UV Marking Machine

In the field of modern precision processing, because the traditional laser marking machine uses laser thermal processing technology, the development of fineness is limited, and the emergence of ultraviolet laser marking machine breaks this deadlock, which uses a kind of cold processing Process, the processing process is called "photoetching" effect, "cold processing" (ultraviolet) photons with high load energy can break the chemical bonds in the material or the surrounding medium, so that the material undergoes non-thermal process damage, and the inner layer and nearby There is no heating or thermal deformation in the area, and the final processed material has smooth edges and extremely low carbonization, so the fineness and thermal influence are minimized, which is a great leap forward in laser technology.

The reaction mechanism of ultraviolet laser processing is realized by photochemical ablation, that is, relying on laser energy to break the bonding between atoms or molecules, making them gasify and evaporate as small molecules. The focused spot is extremely small, and the processing heat-affected zone is very small, so it can be used for ultra-fine marking and special material marking.

3W 5W Laser Marking Machine Characteristic:

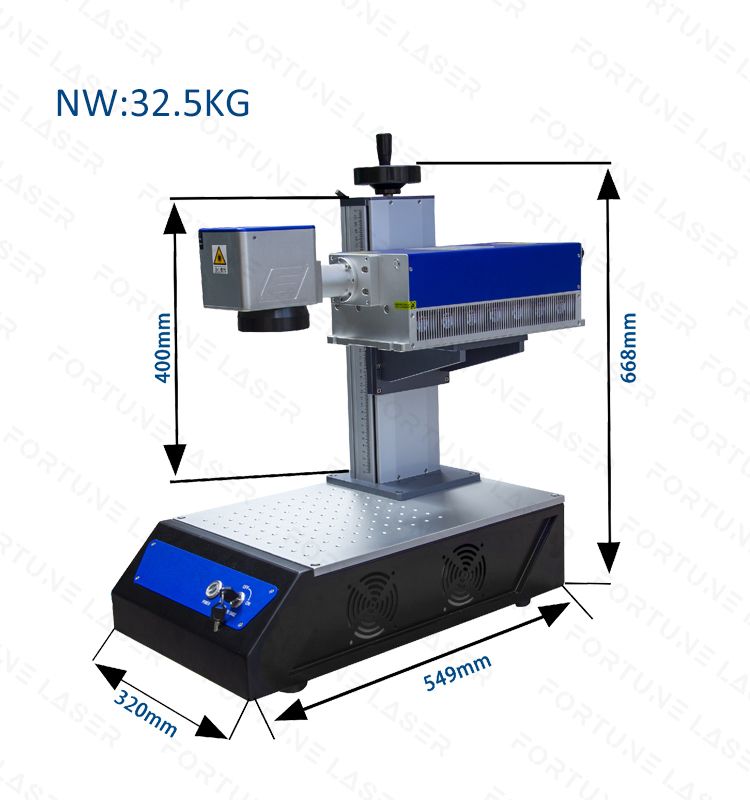

Fortune Laser Automatic Laser Welding Machine Technical Parameters

|

Model |

FL-UV3 |

FL-UV5 |

|

Laser Power |

3W |

5W |

|

Cooling Way |

Air Cooling |

|

|

Laser Wavelength |

355nm |

|

|

Output power |

>3W@30KHz |

>5W@40KHz |

|

Maximum pulse energy |

0.1mJ@30KHz |

0.12mJ@40KHz |

|

Pulse Repetition Frequency |

1-150KHz |

1-150KHz |

|

Pulse duration |

<15ns@30KHz |

<18ns@40KHz |

|

Average power stability |

<3% |

<3% |

|

Polarization ratio |

>100:1 Horizontal |

>100:1 Horizontal |

|

Beam circularity |

>90% |

>90% |

|

Environment Requirement |

Working temp: 18°-26°,

Humidity: 30% - 85%. |

|

|

Control Board & Software |

JCZ EZcad2 |

|