Factory supplied Mini Laser Cutting Machine - Fortune Laser Professional CNC 3D 5-Axis H Beam Laser Cutting System Machine – Fortune

Factory supplied Mini Laser Cutting Machine - Fortune Laser Professional CNC 3D 5-Axis H Beam Laser Cutting System Machine – Fortune

Factory supplied Mini Laser Cutting Machine - Fortune Laser Professional CNC 3D 5-Axis H Beam Laser Cutting System Machine – Fortune Detail:

Machine Characters

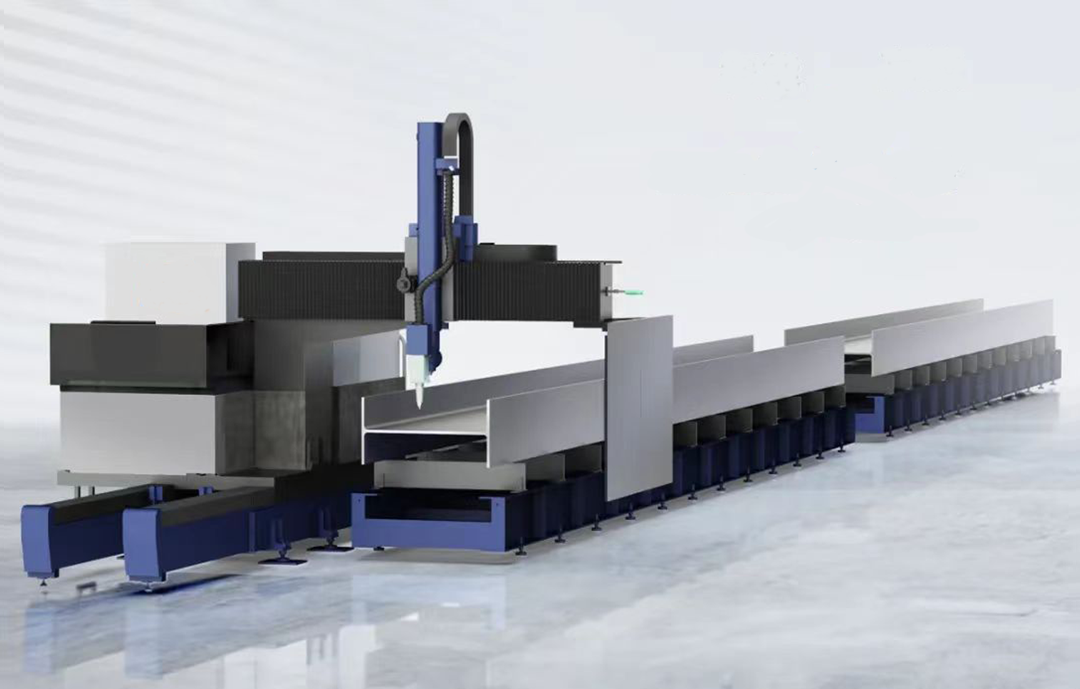

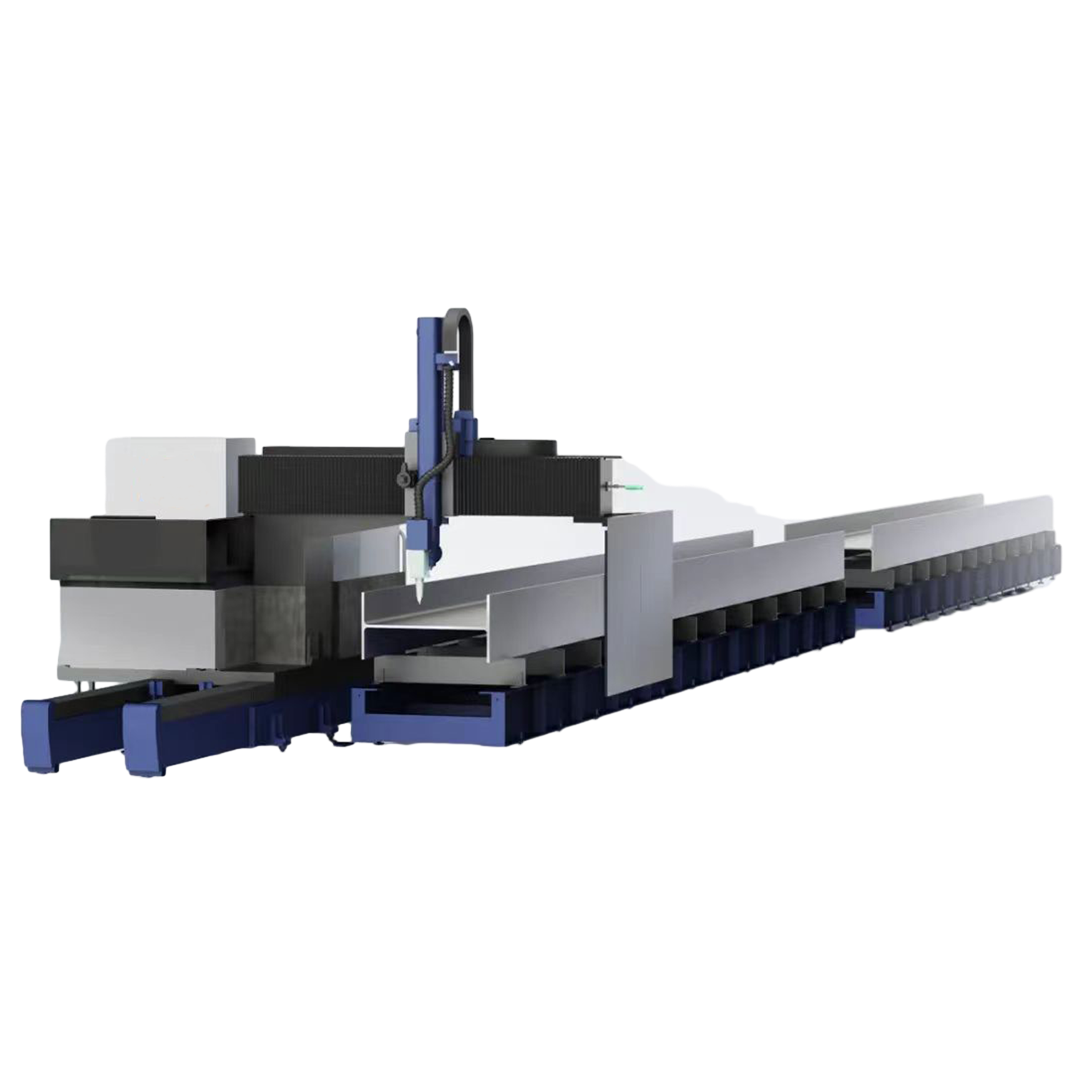

The 12m/24m large H steel/flat plate/bevel cutting machine adopts the German Beckhoff three-dimensional five-axis system. The three-in-one laser cutting production line is a high-tech product that integrates three-dimensional five-axis RTCP CNC technology, laser cutting, precision machinery, and intelligent detection technology. In the field of steel structure processing, traditional manual, flame cutting, plasma cutting, and semi-automatic loading and unloading methods are still used to improve the quality and production efficiency of steel structure processing products and reduce labor costs.

The three-in-one laser cutting production line has strong adaptability and can be customized. It is widely used in professional equipment manufacturing industries such as steel structures, ships, engineering machinery, agricultural machinery, wind power, petroleum, chemical industry, and offshore engineering. It is widely used to realize H-shaped steel, industrial Laser cutting of cross-section steel, C-shaped steel, square steel, curved steel, channel steel, etc.

Machine configuration

| Model | Fiber Laser Cutting Machine FL-H2612 |

| Working Area | 24000mm*12000mm (Length optional) |

| Laser source | Max 12kW/20kw |

| Control SystemThree-dimensional five-axis CNC system | Based on Beckhoff secondary developmentSupports direct import of 3D models such as Tekla and Solidworks to quickly generate processing files. Cutting flat plates/beveling/marking, etc. |

| Laser head | PoLeader |

| Machine bed | Fortune Laser |

| Machine rack and pinion | YYC |

| Precision guide rail | HIWIN |

| Servo Motor Drive | Yaskawa/Inovance EC servo motor and drive |

| Electronic components | France Schneider |

| Reducer system | MOTOREDUCER |

| Air system | AirTAC |

| Machine bed accessories | Fortune Laser |

| Water chiller | Hanli |

| Waste recycling equipment | Fortune Laser |

| HS Code | 8456110090 |

Note: This machine configuration is only for your reference, many other brands for each part of the machines are optional based on your requirements and your budget. Please feel free to contact us for more details.

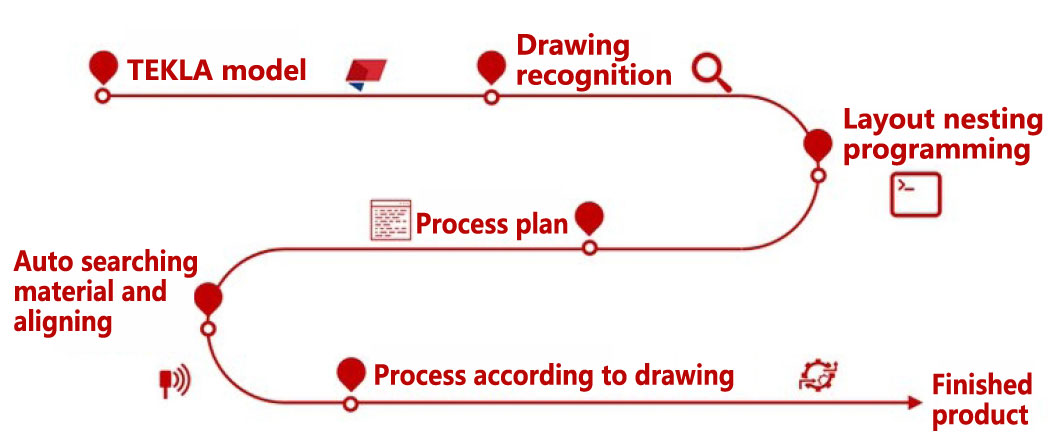

Process design and operation flow

1. Steel section cutting, cutting holes, engraving, marking, lineation – all in one machine;

2. With fine hole cutting technology;

3. Support a variety of groove cutting processes;

4. Support TEKLA steel structure 3D modeling data file cutting.

Operation flow chart:

Machine Features

Moving head

➣ Advanced three-dimensional six-axis five-linkage control technology

➣ Advanced German import control system is selected for secondary development.

➣ Support for advanced technology.

➣ Accurate measurement with laser measuring sensors.

➣ Considering the large deformation of the section steel, the space coordinates are used as the processing basis.

Based on the particularity of steel section cutting, the cutting head of this product is the customized product of Fortune Laser (see No. 6 laser cutting head), with special customized parts. With automatic focus, APP real-time monitoring, coaxial spray auxiliary gas cutting, to ensure the best cutting quality.

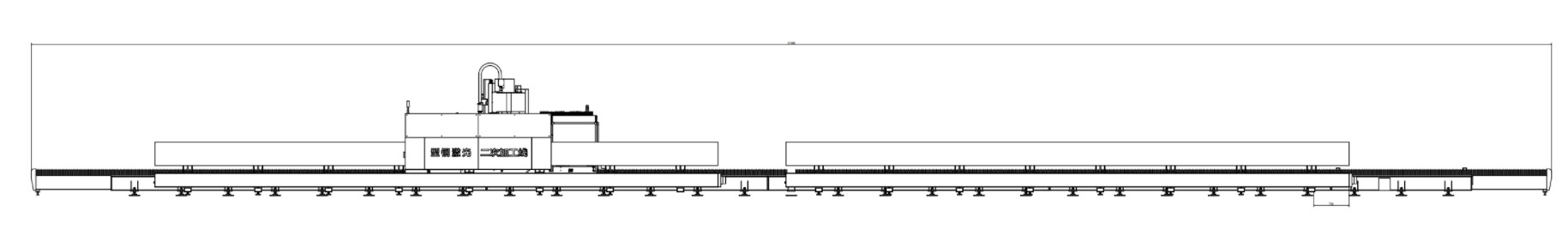

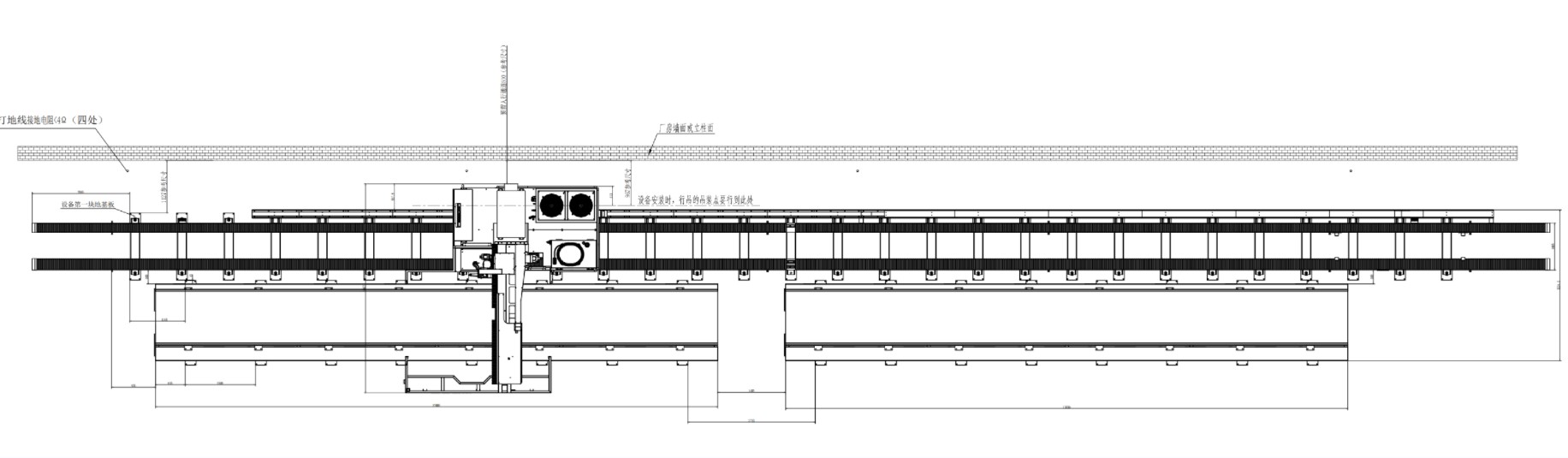

Working table

➣ Double station design: A station cutting at the same time, B station lifting and loading

➣ Automatic material alignment: the use of laser sensor to find the axis of the steel, improve accuracy, save time, save space

➣ Flexible processing: can be segmented processing, can also be full-length processing

Guide rail machine table

Structural features and accuracy guarantee: the cantilever and column are installed on the linear guide rail, and the servo motor and high-precision reducer drive the gear and rack transmission.

Steel laser secondary processing line enterprise standard: straightness error ≤0.02/m.

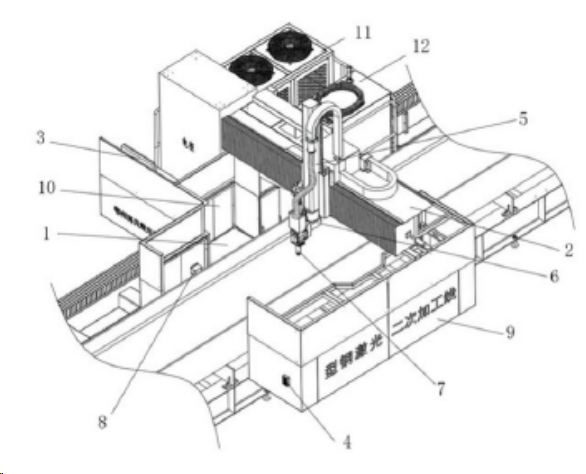

Main parts description

1. Moving platform

2. Cantilever frame

3. Control center

4. Remote controller

5. Z axis

6. AC axis

7. Cutting head

8. Laser sensor

9. Protective cover

10. Graphite shield

11. Water chiller

12. Laser power

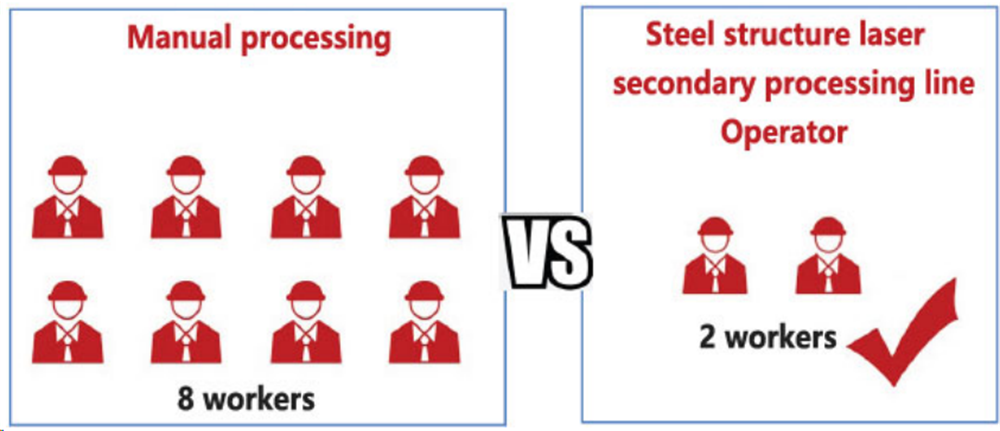

Compared with traditional manual processing

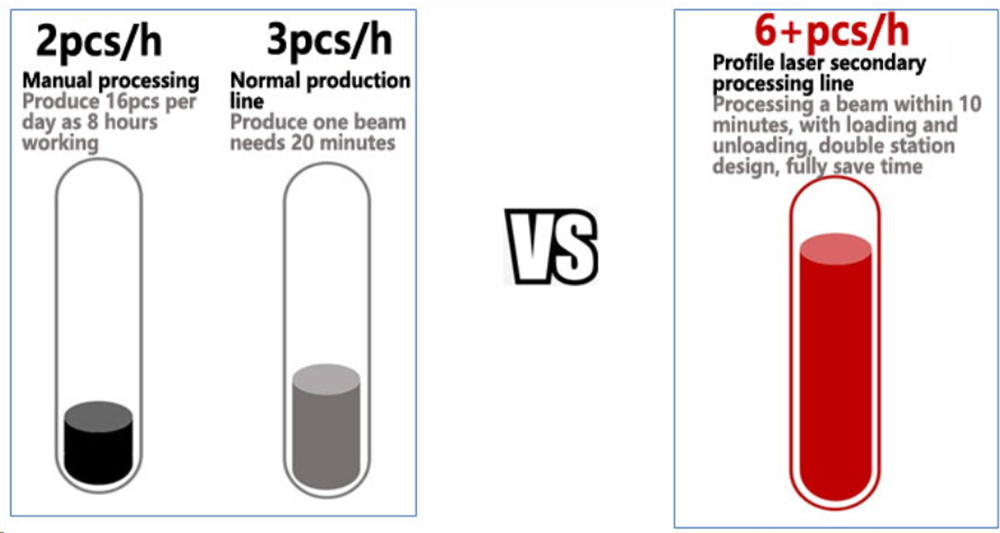

Take the daily processing of 50pcs 12m H-beam steel (600x200mm) (single 28-hole) workpiece as an example.

Labor efficiency comparison

The larger the workpiece, the more obvious the advantages of the laser processing line

Processing efficiency comparison (on 8-hour working day)

Machining accuracy comparison

Manual: 1mm~2mm

Laser secondary processing line: 0.2mm~0.5mm

Processing cost comparison

Manual: 28 CNY/piece

Laser secondary processing line: 9 CNY/piece

Laser cutting head

The laser cutting head adopts the PoLeader 3.0s ultra-high power intelligent focusing optical fiber cutting head. Suitable for QBH, Q+, QD and other fiber interfaces, the maximum power of 30KW PoLeader 3.0s will bring higher quality and faster cutting experience to the laser processing industry. The newly designed cooling method can bring more efficient cooling effect to the optical lens, ensuring the stability of batch cutting; The new double cover plate plus drawer design solves the trouble of protection and focus protection under field replacement, as well as the risk of falling ash.

Technical parameters:

Applicable optical fiber power: ≤30KW

Focusing lens focal length: 200mm

Focus adjustment range: +25mm ~ -30mm

Control mode: analog control, EtherCAT control

Double upper protective mirror size: ø24.2mm*2mm

Lower protective mirror size: ø37mm*7mm

Auxiliary gas pressure: ≤2.5MPa

Weight: 9~12KG

Product advantages:

➣ The new double cover plate design greatly improves the sealing, the process of replacing the protective mirror is more safe and efficient, and effectively extends the service life of the cutting head

➣ New bus communication, signal transmission is faster and more stable; Zoom is faster and more accurate

➣ Newly designed whole-body water cooling method, more efficient cooling optical lenses; The stability of batch cutting is ensured.

➣ The monitoring data can be read in real time on mobile terminal and host computer through wireless network and the newly added EtherCAT communication.

➣ A new double intake cutting gas path is designed to solve the problem of cutting directionality caused by the influence of the gas path during plate cutting, and ensure the consistency of the finished products in all directions.

Laser power source (Option 1)

The Multi-module CW Fiber Lasers developed by Raycus is with high electro-optical conversion efficiency, high light beam quality, high energy density, wide modulation frequency, high reliability, long service life, maintenance-free operation and advantages. The product can be widely applied in welding, precision cutting, melting and cladding, surface processing, 3Dprinting and other fields. Its optical output performance helps it better integrate with robots as a flexible manufacturing equipment to meet 3D processing requirement.

Product characteristics:

➣ High electro-optical conversion efficiency

➣ The output optical fiber length can be customized

➣ QD connector

➣ maintenance-free operation

➣ Wide modulation frequency range

➣ anti-high reaction capability

➣ Efficient sheet cutting

Technical information of laser device:

|

Name |

Type |

Parameter |

|

Laser device (Raycus 12000W fiber laser) |

Length of wave | 1080±5nm |

| Rated output | 12000W | |

| Light quality (BPP) | 2-3(75μm)/3-3.5(100μm) | |

| Laser working way | Constant adjusting | |

| Cooling way | Water cooling | |

| Max cutting (When cutting thick plate, due to material and other reasons, burrs may occur) | C.S: ≤30mmS.S: ≤30mm |

Laser power source (Option 2)

The Multi-module CW Fiber Lasers developed by Raycus ranges from 3,000W to 30kW, with high electro-optical conversion efficiency, high light beam quality, high energy density, wide modulation frequency, high reliability, long service life, maintenance-free operation and advantages. The product can be widely applied in welding, precision cutting, melting and cladding, surface processing, 3Dprinting and other fields. Its optical output performance helps it better integrate with robots as a flexible manufacturing equipment to meet 3D processing requirement.

Product characteristics:

➣ High electro-optical conversion efficiency

➣ The output optical fiber length can be customized

➣ QD connector

➣ maintenance-free operation

➣ Wide modulation frequency range

➣ anti-high reaction capability

➣ Efficient sheet cutting

Technical information of laser device:

|

Name |

Type |

Parameter |

|

Laser device (Raycus 20000W fiber laser) |

Length of wave | 1080±5nm |

| Rated output | 20000W/30000W | |

| Light quality (BPP) | 2-3(75μm)/3-3.5(100μm) | |

| Laser working way | Constant adjusting | |

| Cooling way | Water cooling | |

| Max cutting (When cutting thick plate, due to material and other reasons, burrs may occur) | C.S: ≤50mmS.S: ≤40mm |

Control software and nesting software

The CNC operating system adopts the laser secondary processing line system of the shaped steel custom-developed by Fortune Laser, which is convenient to operate, stable to run and has excellent dynamic performance.

➣ It has a cutting process library to help users achieve the best cutting quality.

➣ Draws or edits 2D graphical trajectories directly within the machining system without the need for third-party software, increasing productivity and providing asymmetric acceleration and deceleration calculations for silky lubrication.

➣ Electric lubrication system improves equipment life.

➣ It provides standard modular functions such as one-click cut-off, automatic calibration, and regional dust extraction.

➣ Thin plate non-inductive perforation, thick plate lightning perforation, multi-stage perforation, perforation slag removal, vibration suppression, pressure closed loop, layer division fine technology and other functions greatly improve the efficiency and stability of high-power cutting, improve the core competitiveness of equipment.

➣ High speed and high precision automatic edge finding to meet the requirements of profiled material and higher precision.

➣ Realize anti-interference ultra-long distance transmission of display signal, IO signal and USB signal.

➣ Torque deviation anti-collision protection, air movement obstacle avoidance, intelligent leapfrog and other functions.

The nesting software adopts the special software for the custom-developed laser secondary processing line of the profile steel, which is convenient to operate, with automatic identification function and fast processing of batch documents.

➣ supports the direct import of Tekla, Solidworks and other 3D models, and can directly draw or edit the graph trajectory of section steel cutting in the nesting software, without the cooperation of third-party software, improving the debugging and adjustment efficiency

➣ converts or processes files in batches, supports automatic processing of multiple connected nodes, and automatically optimizes cutting paths to support common edge cutting.

➣ The software has high stability, and the corresponding process database can be set according to different materials and plate thickness.

Machine Parameters

| No. | Items/Model | FL-H2612 |

| 1 | Beam cutting range | Height: 100-500mm |

| Width: 250-1200mm | ||

| Length: ≤26000mm | ||

| 2 | X axis moving stroke | 1800mm |

| 3 | Y axis moving stroke | 26000mm |

| 4 | Z axis moving stroke | 910mm |

| 5 | X/Y axis positioning accuracy | ±0.25mm |

| 6 | X/Y axis repeat positioning accuracy | ±0.05mm |

| 7 | X/Y/Z axis max. speed | 30m/min |

| 8 | A axis swing angle | ±90° |

| 9 | B axis swing angle | ±90° |

| 10 | Max. accelerated speed | 0.2G |

| 11 | Phase | 3 |

| 12 | Power spec. | 380V/50HZ |

| 13 | Power supply protection class | IP54 |

| 14 | Laser source | Max/Raycus 12KW or 20KW |

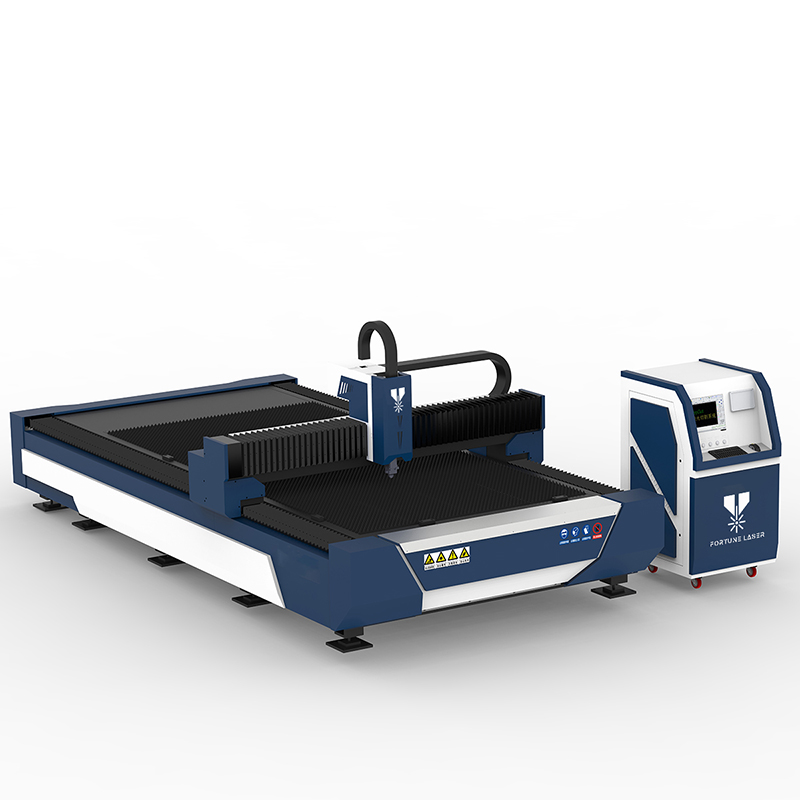

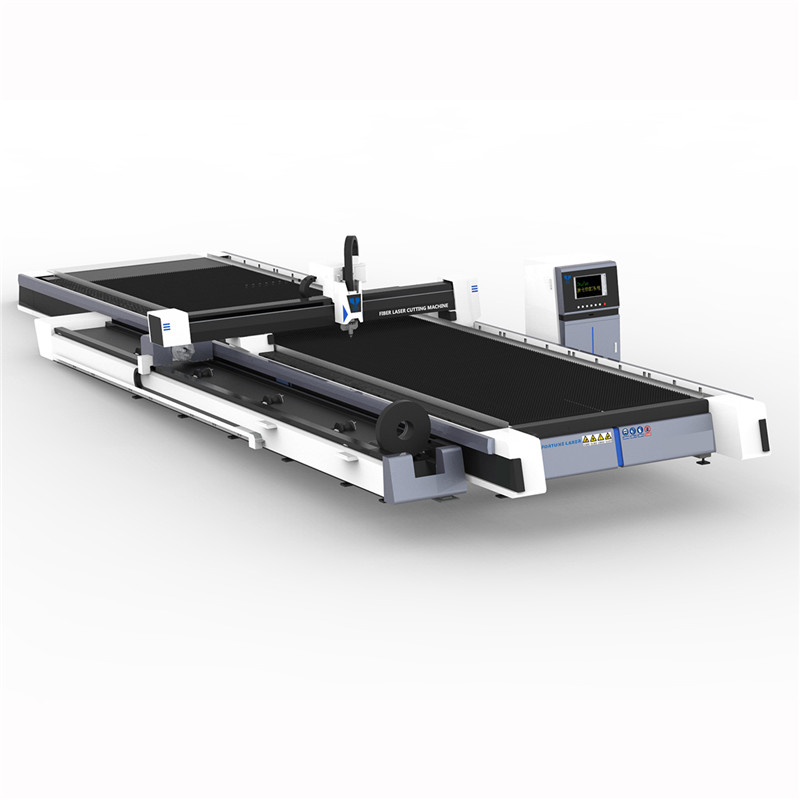

Machine Display

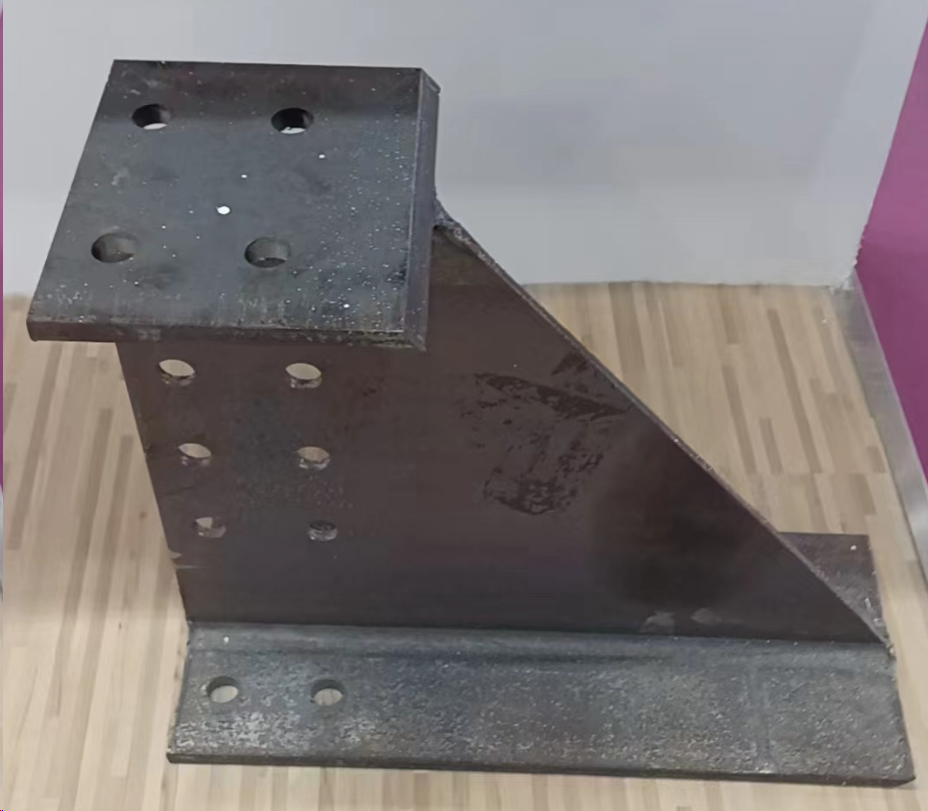

Samples Display

Precise alignment and easy installation

Through welding hole cutting display as above

Section steel 45 degree bevel cutting display

Product detail pictures:

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for Factory supplied Mini Laser Cutting Machine - Fortune Laser Professional CNC 3D 5-Axis H Beam Laser Cutting System Machine – Fortune , The product will supply to all over the world, such as: Netherlands, Denmark, Mongolia, Our focus on product quality, innovation, technology and customer service has made us one of undisputed leaders worldwide in the field. Bearing the concept of "Quality First, Customer Paramount, Sincerity and Innovation" in our mind, We have achieved great progress in the past years. Clients are welcomed to buy our standard products, or send us requests. You will be impressed by our quality and price. Please contact us now!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.