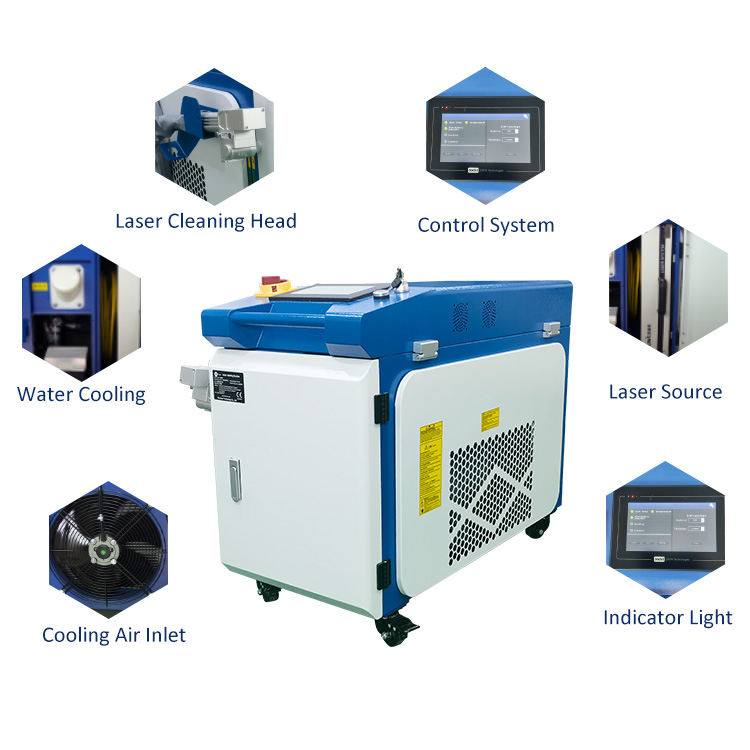

Continuous Laser Cleaning Machine Rust Removal Machine

Continuous Laser Cleaning Machine Rust Removal Machine

Product description

Laser cleaning machine, also known as laser cleaner or laser cleaning system, is an advanced equipment that uses high-energy density laser beam to achieve efficient, fine and deep cleaning. It is favored for its excellent cleaning efficiency and environmental performance. This equipment is designed for high-performance surface treatment. Combined with modern laser technology, it can quickly and accurately remove rust, paint, oxides, dirt and other surface contaminants while ensuring that the surface of the substrate is not damaged and maintains its original integrity and finish.

The design of the laser cleaning machine is not only compact and lightweight, but also highly portable, which is convenient for users to operate easily and can achieve dead-angle cleaning even on complex surfaces or hard-to-reach areas. The equipment has shown excellent application value in many fields such as manufacturing, automotive industry, shipbuilding, aerospace, and electronic manufacturing.