China Manufacturer for Laser Tool Welding - Wobble Head 3 in 1 Handheld Laser Welder Cleaner Cutter – Fortune

China Manufacturer for Laser Tool Welding - Wobble Head 3 in 1 Handheld Laser Welder Cleaner Cutter – Fortune

China Manufacturer for Laser Tool Welding - Wobble Head 3 in 1 Handheld Laser Welder Cleaner Cutter – Fortune Detail:

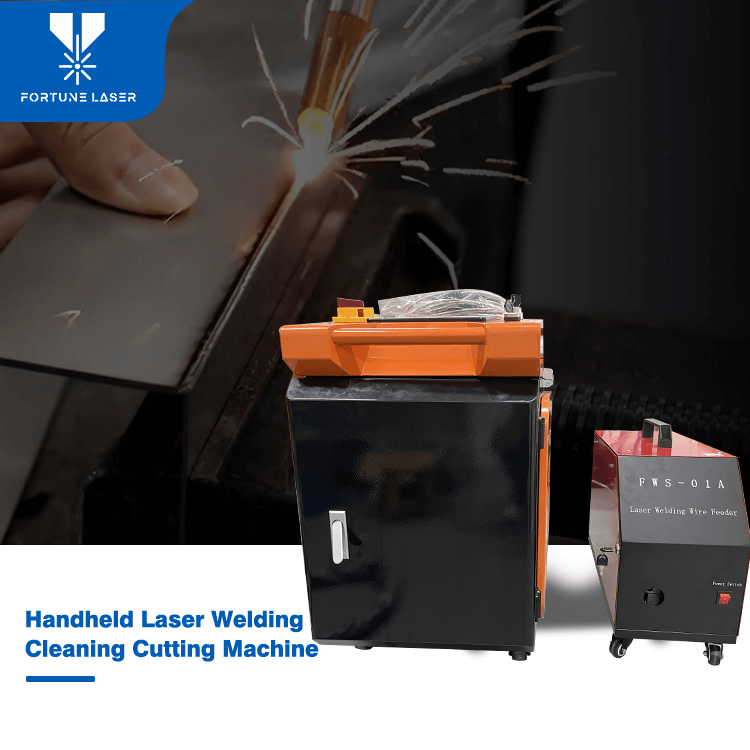

Features of 3 IN 1 Laser Machine

1.Wide welding range: the hand-held welding head is equipped with 10M original optical fiber, which overcomes the limitation of the workbench space and can be used for outdoor welding and long-distance welding;

2.Convenient and flexible use: Hand-held laser welding is equipped with moving pulleys, which is comfortable to hold and can adjust the station at any time without fixed-point stations. It is free and flexible, and is suitable for various working environment scenarios.

3.A variety of welding methods: welding at any angle can be realized: lap welding, butt welding, vertical welding, flat fillet welding, inner fillet welding, outer fillet welding, etc., and can be used for workpieces with various complex welds and irregular shapes of larger workpieces welding. Realize welding at any angle. In addition, it can also complete the cutting, welding and cutting can be switched freely, just change the welding copper nozzle to the cutting copper nozzle, which is very convenient.

4.Cutting, welding, and cleaning are often closely connected upper and lower processes in metal processing operations. The traditional operation method often requires three different operating equipment to carry out three processes. In response to this problem, we provide customers with an integrated solution and launch a handheld laser cutting and welding all-in-one machine! This is a device with triple functions of laser welding, cleaning and cutting.

5. Quickly and easily removes oil, rust and coatings before welding, and removes debris and discoloration after welding, while performing cutting processes on a variety of plates. It can conveniently and efficiently help customers achieve the best work efficiency and meet most work scenarios. The welding swing width is as high as 5mm, and the cleaning swing length is up to 100mm. It can cut stainless steel plates below 6mm. The process index is strong, especially the cleaning index is almost unmatched!

Fortune Laser Mini Laser Welding Machine Basic Technical Parameters

|

Model |

FL-HW1000M |

FL-HW1500M |

FL-HW2000M |

|

Laser Power |

1000W |

1500W |

2000W |

|

Cooling Way |

Water Cooling |

Water Cooling |

Water Cooling |

|

Laser Wavelength |

1080nm |

1080nm |

1080nm |

|

Laser Head |

Dual Axis |

||

|

Way of Working |

Continuous/ Modulation |

||

|

Fiber Length |

Standard 10m, the longest customized length 15m |

||

|

Dimension |

100*68*45cm |

||

|

Weight |

165kg with wire feeder |

||

|

Options |

Portable |

||

|

Welding thickness |

0.5-3mm |

||

|

Speed range of welder |

0-120mm/s |

||

|

Temperature |

15-35℃ |

||

|

Operating Voltage |

AV 220V |

||

|

Focal Spot Diameter |

0.5mm |

||

|

Welding thickness |

0.5-5mm |

||

Welding penetration parameters (Material & Thickness Welding Range) for reference

|

Material |

Output power (W) |

Maximum penetration (mm) |

| Stainless steel | 1000 | 0.5-3 |

| Stainless steel | 1500 | 0.5-4 |

| Stainless steel | 2000 | 0.5-5 |

| Carbon steel | 1000 | 0.5-2.5 |

| Carbon steel | 1500 | 0.5-3.5 |

| Carbon steel | 2000 | 0.5-4.5 |

| Aluminum alloy | 1000 | 0.5-2.5 |

| Aluminum alloy | 1500 | 0.5-3 |

| Aluminum alloy | 2000 | 0.5-4 |

| Galvanized sheet | 1000 | 0.5-1.2 |

| Galvanized sheet | 1500 | 0.5-1.8 |

| Galvanized sheet | 2000 | 0.5-2.5 |

[Orange/Black and White/Blue two machine colors (show as in the picture) are for option.]

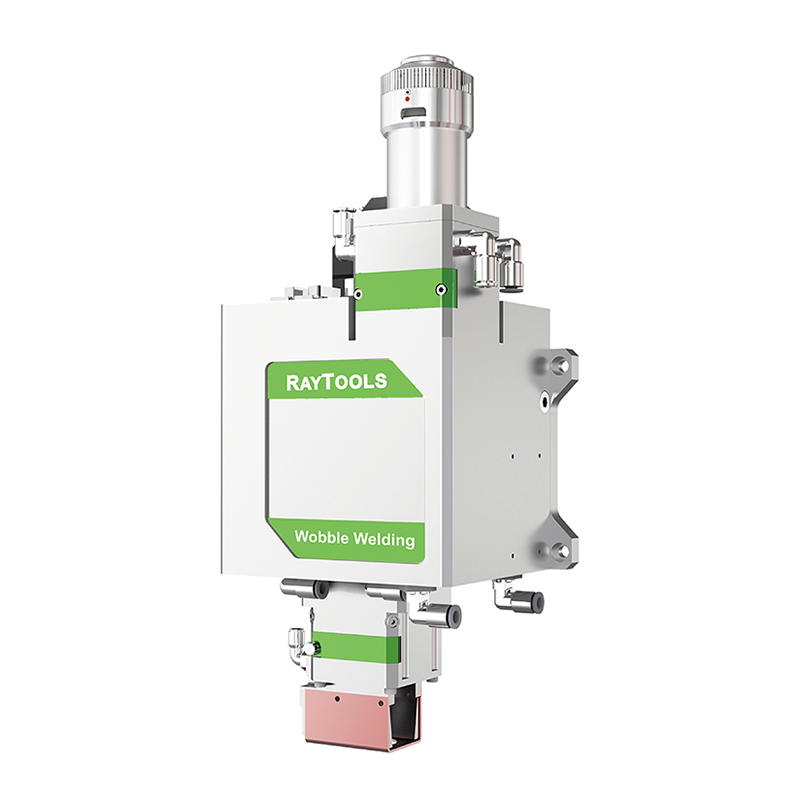

About Fortune Laser 3 In 1 Laser Head Features:

1. This welding head has strong advantages in stainless steel, aluminum alloy welding, and small and medium power welding applications. It is a costeffective welding head.

2. The welding head adopts motor-driven X, Y-axis vibrating lens, with multiple swing modes, and swing welding allows the workpiece to have irregular welding, larger gaps and other processing parameters, which can significantly improve the welding quality.

3. The internal structure of the welding head is completely sealed, which can prevent the optical part from being polluted by dust.

4. Optional welding/cutting kits and cleaning kits can truly achieve three functions of welding, cutting and cleaning.(We also have a mini cleaning machine with separate cleaning function)

5. The protective lens adopts a drawer structure, which is easy to replace.

6. Can be equipped with various lasers with QBH connectors.

7. Small size, good appearance and feel.

8. A touch screen is optional on the welding head, which can be linked with the platform screen for better man-machine control experience

Laser head details:

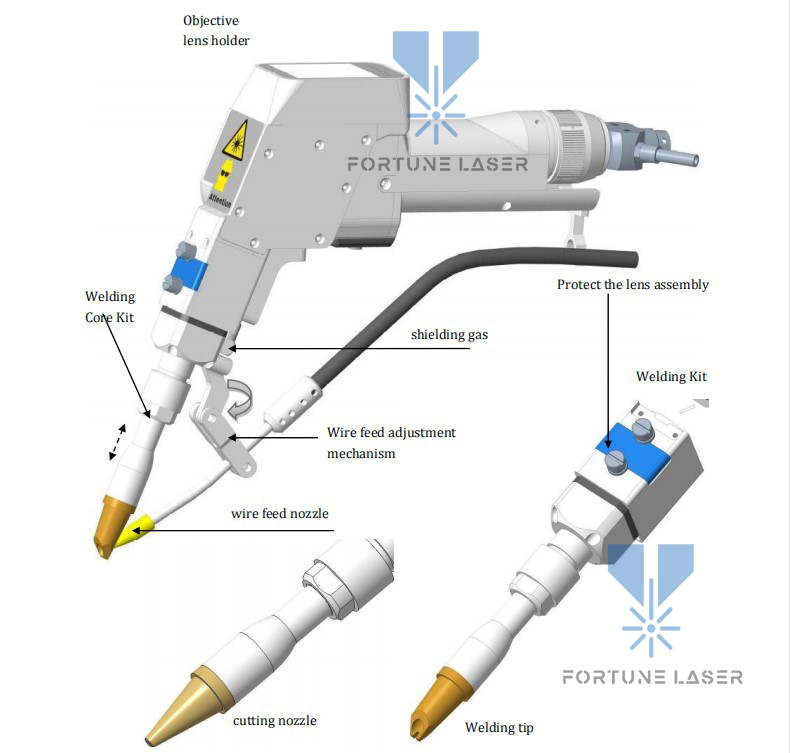

1)Double pendulum hand-held welding head

Including body part + optional: cleaning kit, welding with cutting kit part, which can be selected according to customer needs.

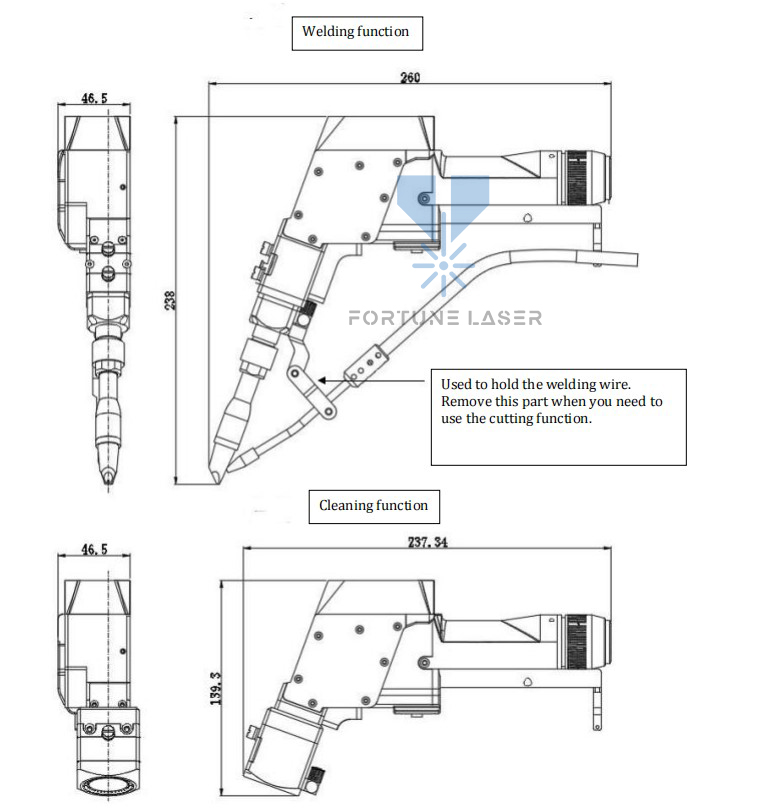

2)Outline drawing of welding head:

This double pendulum welding head uses a fiber laser as the light source, and operates in a hand-held and flexible manner to the parts that need to be weld, cut, clean and destructed.

This laser head welds accurately, durable, easy to maintain and easy to adjust.

All media connections are built into the laser head!

3)Welding head kit (weld and cut):

When you need to cut, you only need to unscrew the welding nozzle, screw the cutting nozzle on, and adjust the focal length to cut.

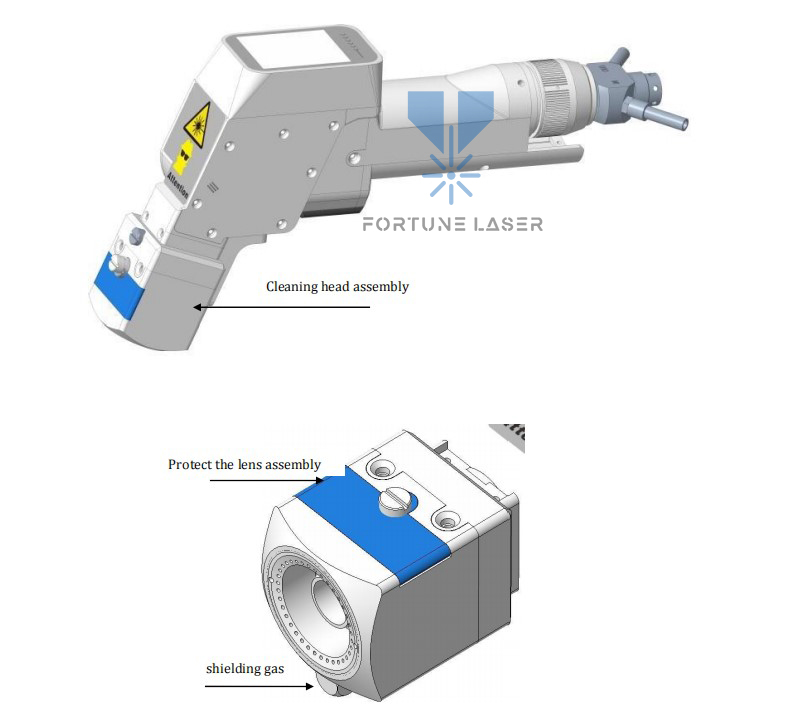

3)Cleaning head

When cleaning is required, remove the welding core kit, screw on the cleaning head, and clean and remove rust within the focal length range.(There is also a large-format cleaning machine with a cleaning range of 300mm)

Laser head parameters:

|

Supply voltage (V) |

220V±10% AC 50/60Hz |

|

Rated power |

1500W |

|

Collocated focal length |

75mm |

|

Working environment humidity(%) |

<70 |

|

Focus/Clean Focal Length |

F150mm/F500mm |

|

Swing range |

0.1-5mm |

|

Cooling method |

Water chiller |

|

Swing frequency |

0—300Hz |

|

Weight |

0.8kg |

|

Optional |

Cleaning Head / Wire Feeder / Cutting Tip / Welding Kit |

|

Screen size |

Standard large screen + optional 2-inch small screen |

|

Focus vertical adjustment range |

±10mm |

|

Spot adjustment range (handheldwelding mode) |

0~6mm |

|

Spot adjustment range (cleaningmode) |

0~50mm |

Is it easy to operate the machine?

All the operation interfaces of our machines are simple and easy to understand. Select the parameters you want to change through the touch screen and save them. The cleaning and welding functions are easy to switch. Just select the options on the machine and it will change to the mode you want.

And many friends who have not used it will also wonder how to adjust the parameters. We will set the parameters suitable for you when we ship the product. When using it, you only need to change the power to use it. If you still feel uneasy, we also have a set of research. The parameter table suitable for welding of various materials is for our customers’ reference.

The optical path, system, hardware, etc. are all independently developed. The operation interface is intuitive and simple, and the operation is simple. Hours of training can make you feel like a skilled welder. Reduce labor costs while improving quality, consistency, and productivity.

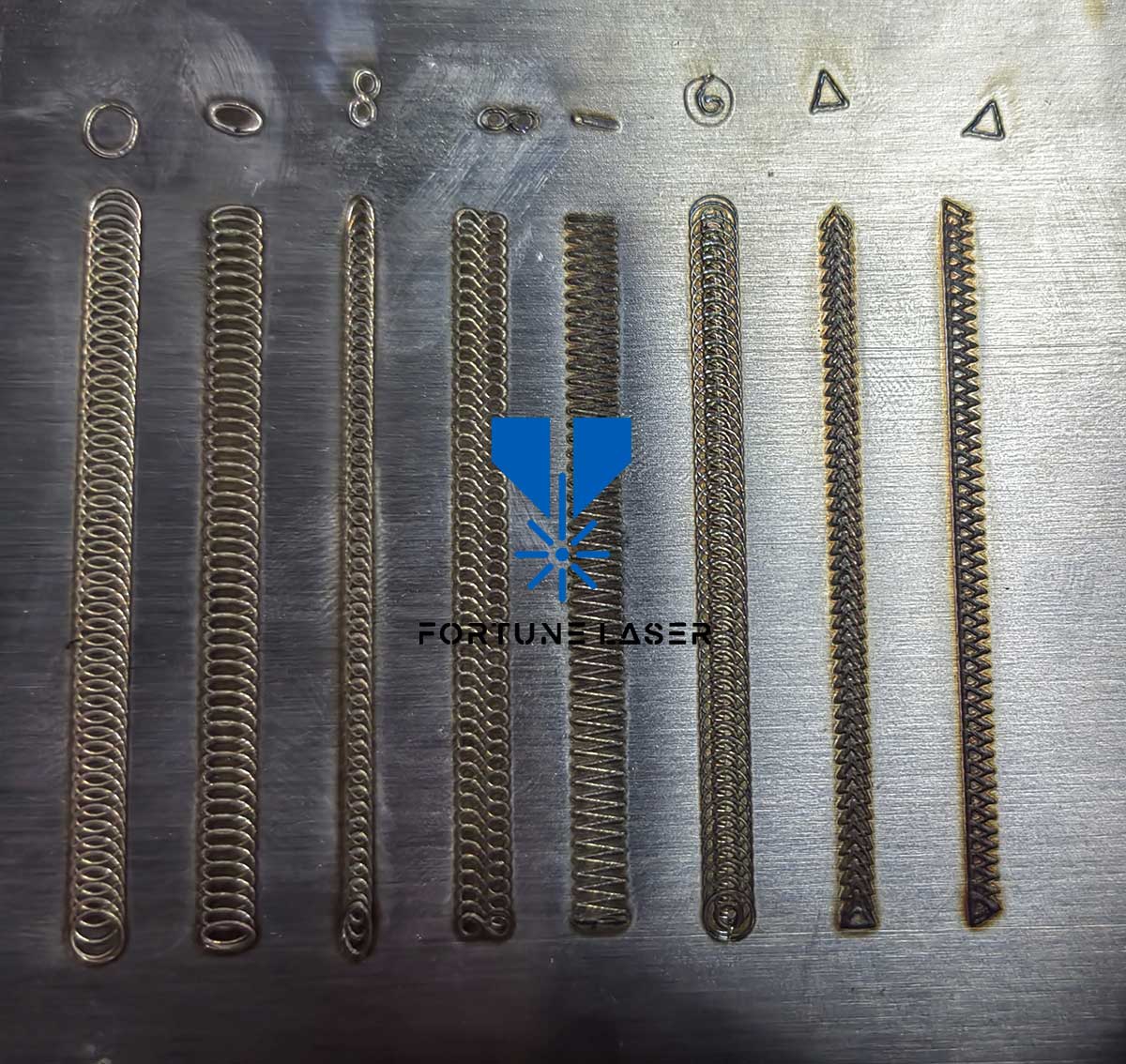

How many spot shapes can our machine change?

On the basis of 3 and 1, our machine can also change different kinds of spot shapes as show in the picture below.

The patterns welded by each beam shape are different. Our beam shapes include straight line, circle, triangle, figure 8, ellipse, 90° and other common shapes.

Why choose us?

1.This laser head is our exclusive customized product, there is almost no similar one on the market;

2.We have multiple B2B shopping platforms, which can guarantee the safety of your purchase;

3.We have dedicated technical support and 24-hour after-sales service to improve customer experience;

4.All of our machines have a 1-year warranty.

5.We focus on developing our products creatively and offer competitive terms.

6.We have a very competent and reliable team at your service, committed to providing a personalized customer service to all of our clients.

Product detail pictures:

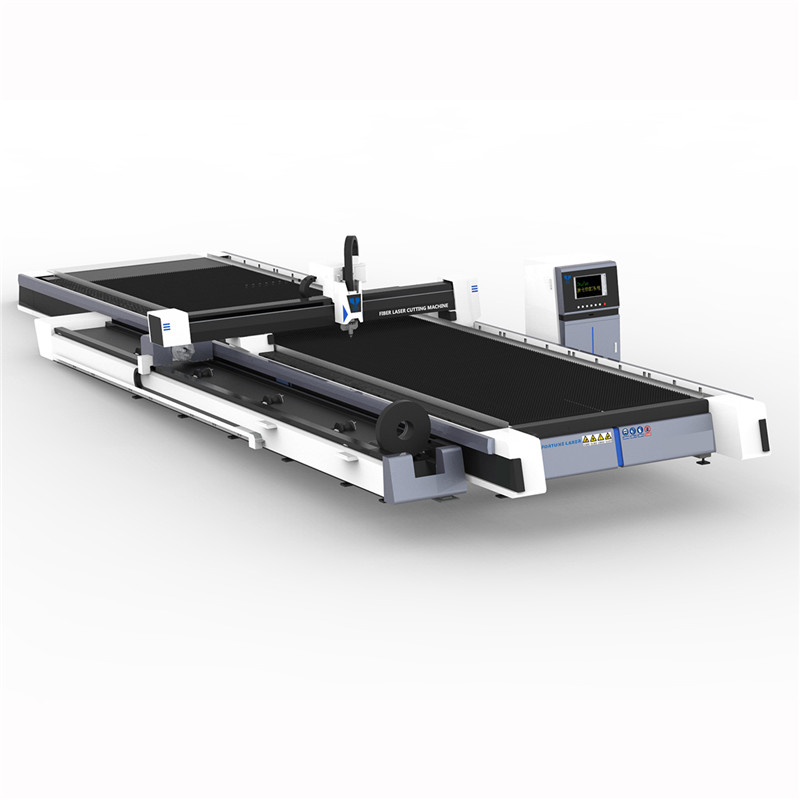

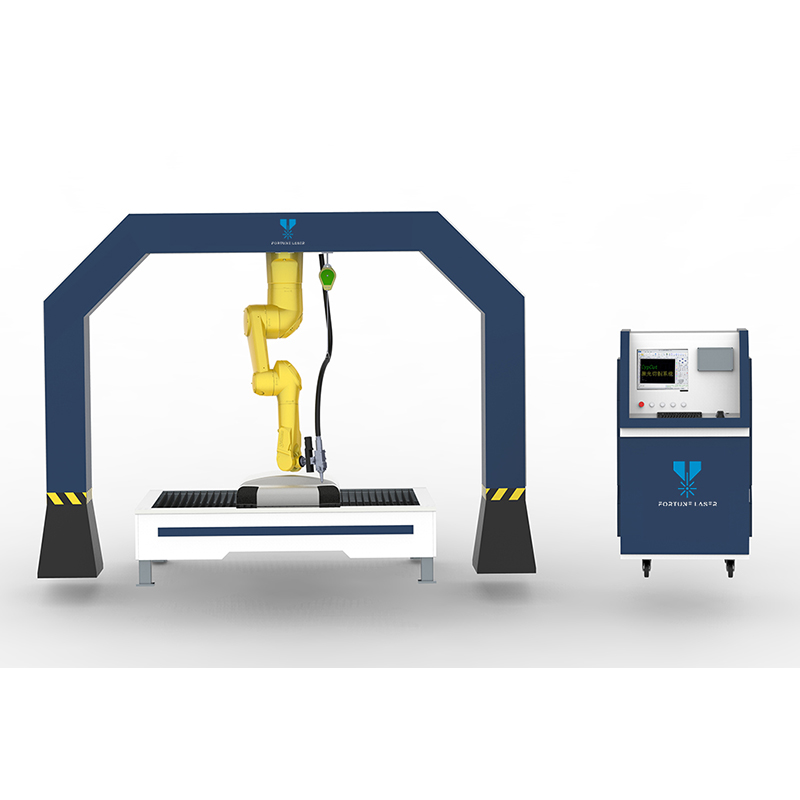

Related Product Guide:

Each individual member from our large performance revenue crew values customers' needs and company communication for China Manufacturer for Laser Tool Welding - Wobble Head 3 in 1 Handheld Laser Welder Cleaner Cutter – Fortune , The product will supply to all over the world, such as: kazan, Maldives, Sacramento, Over the years, with high-quality solutions, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We offer high quality product and competitive price, welcome the regular and new customers cooperate with us!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.