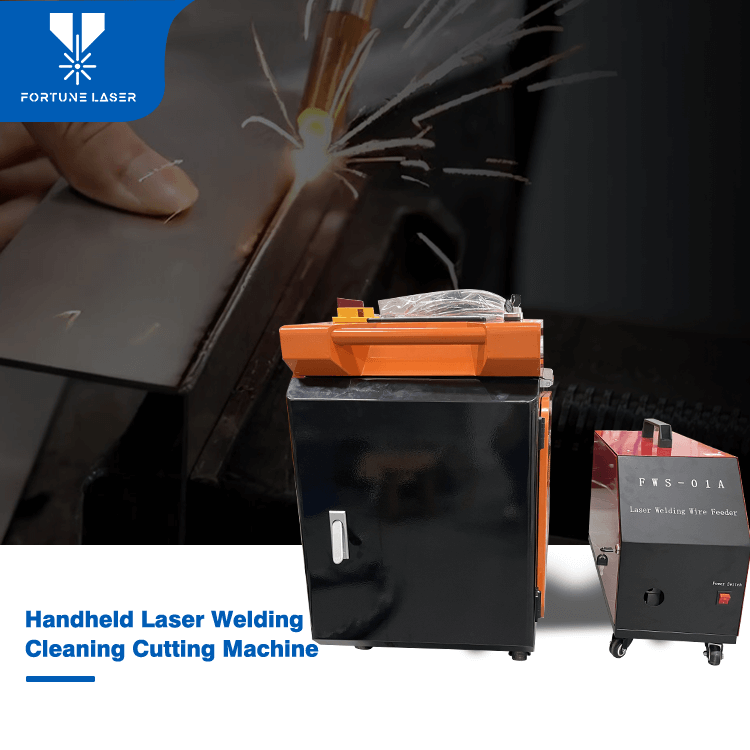

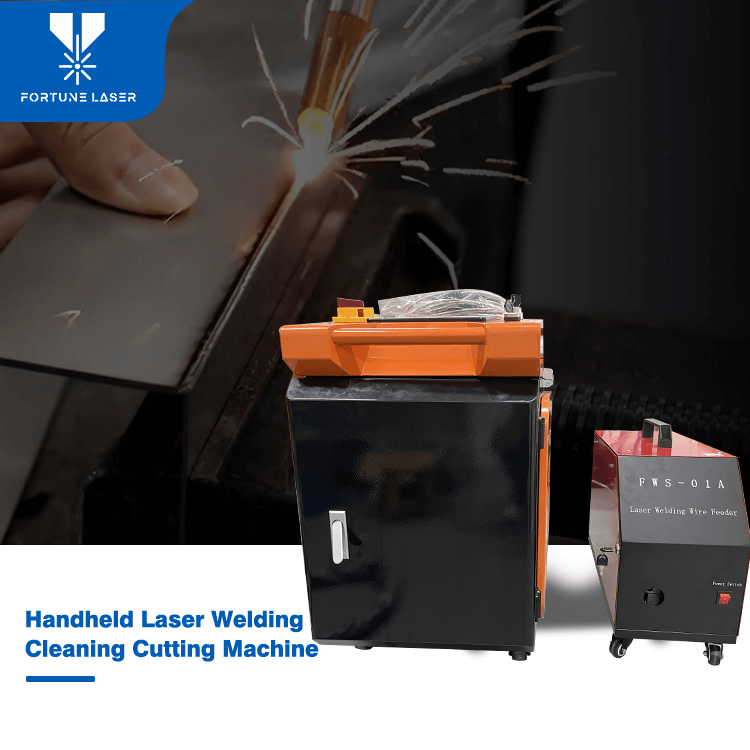

100% Original Robotic Laser Welding Machine - Fortune Laser Hot Sale 1000W-3000W 3 In 1 Laser Systsem Handheld Laser Welding Cleaning Cutting Machine – Fortune

100% Original Robotic Laser Welding Machine - Fortune Laser Hot Sale 1000W-3000W 3 In 1 Laser Systsem Handheld Laser Welding Cleaning Cutting Machine – Fortune

100% Original Robotic Laser Welding Machine - Fortune Laser Hot Sale 1000W-3000W 3 In 1 Laser Systsem Handheld Laser Welding Cleaning Cutting Machine – Fortune Detail:

Features of Fortune Laser Welding Machine

1. The integrated structure design of the whole machine, the equipment occupies a small space, and is equipped with large universal casters, which is easy to carry and carry;

2. A variety of welding contact tips are equipped as standard to meet a variety of welding needs, and can achieve high-precision welding. The weld seam is small, beautiful and firm;

3. Professional laser welding software, powerful and easy to learn and use, general workers can be employed after training, no need for professional welders;

4. The equipment has strong expandability, and can be connected to wire feeders, robots, etc., and can be equipped with single pendulum or double pendulum welding joints;

5. The electric control area is equipped with a cooling fan as standard, which can effectively improve the welding stability in high temperature environment (optional cabinet air conditioner);

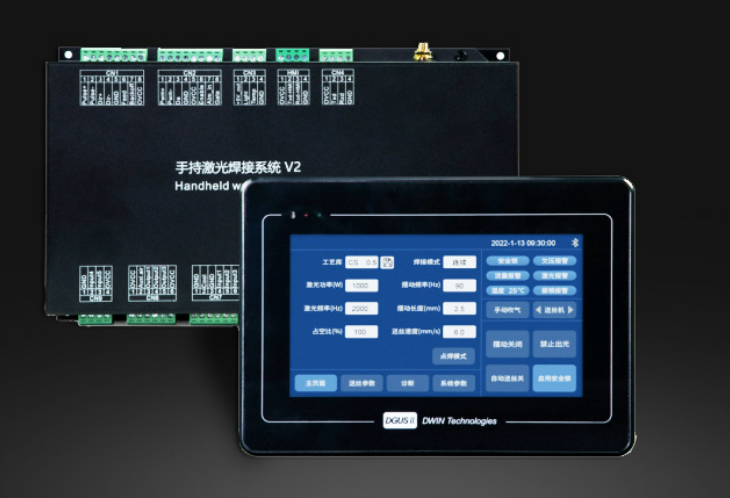

6. Visual instrument and water injection port can be observed at any time during use, and the touch screen control panel is used at the same time to modify the process parameters more intuitively and conveniently;

7. The system can store a variety of different process parameters, which can be switched at any time through the touch screen according to the processing requirements, which significantly reduces the parameter debugging time.

Do you also have these troubles?

1.The Weld is not safe

2.The weld is not beautiful

3.High labor cost

Our machines can give you the perfect solution.

Powerful performance, more intelligent operation, independent warning, self-protection and quick troubleshooting

Intelligent detection, monitoring and protection device: lens temperature setting value, when the lens temperature exceeds the setting value, an alarm will appear on the main page to remind the side of the handheld laser head and the indicator light will be red at the same time

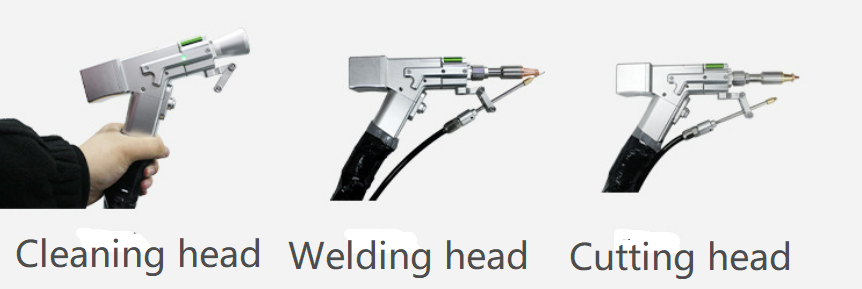

Simple operation, three functions can be switched at any time

Fortune Laser Economy Laser Welding Machine Technical Parameters

|

Model |

FL-HW1000 |

FL-HW1500 |

FL-HW2000 |

FL-HW3000 |

|

Laser Power |

1000W |

1500W |

2000W |

3000w |

|

Cooling Way |

Water Cooling |

Water Cooling |

Water Cooling |

Water Cooling |

|

Laser Wavelength |

1080nm |

1080nm |

1080nm |

1080nm |

|

Laser Head |

Dual Axis |

|||

|

Way of Working |

Continuous/ Modulation |

|||

|

Fiber Length |

Standard 10m, the longest customized length 15m |

|||

|

Dimension |

100*68*45cm |

|||

|

Weight |

165kg with wire feeder |

|||

|

Options |

Portable |

|||

|

Welding thickness |

≤6mm |

|||

|

Speed range of welder |

0-120mm/s |

|||

|

Temperature |

15-35℃ |

|||

|

Operating Voltage |

1000W-2000W, AV 220V, 50/60Hz. 3000W, AV 380V, 50/60Hz |

|||

|

Focal Spot Diameter |

0.5mm |

|||

|

Welding thickness |

0.5-5mm |

|||

Welding penetration parameters

|

Material |

Output power (W) |

Maximum penetration (mm) |

| Stainless steel | 1000 | 0.5-3 |

| Stainless steel | 1500 | 0.5-4 |

| Stainless steel | 2000 | 0.5-5 |

| Stainless steel | 3000 | 0.5-6 |

| Carbon steel | 1000 | 0.5-2.5 |

| Carbon steel | 1500 | 0.5-3.5 |

| Carbon steel | 2000 | 0.5-4.5 |

| Carbon steel | 3000 | 0.5-5.5 |

| Aluminum alloy | 1000 | 0.5-2 |

| Aluminum alloy | 1500 | 0.5-3 |

| Aluminum alloy | 2000 | 0.5-4 |

| Aluminum alloy | 3000 | 0.5-5 |

| Galvanized sheet | 1000 | 0.5-1.2 |

| Galvanized sheet | 1500 | 0.5-1.8 |

| Galvanized sheet | 2000 | 0.5-2.5 |

| Galvanized sheet | 3000 | 0.5-3.1 |

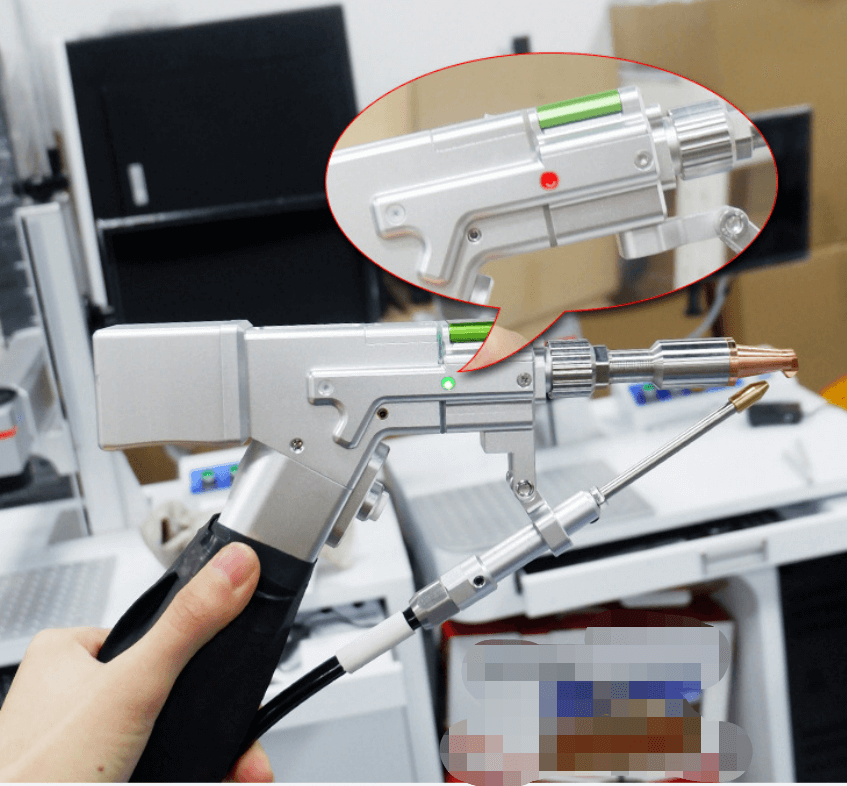

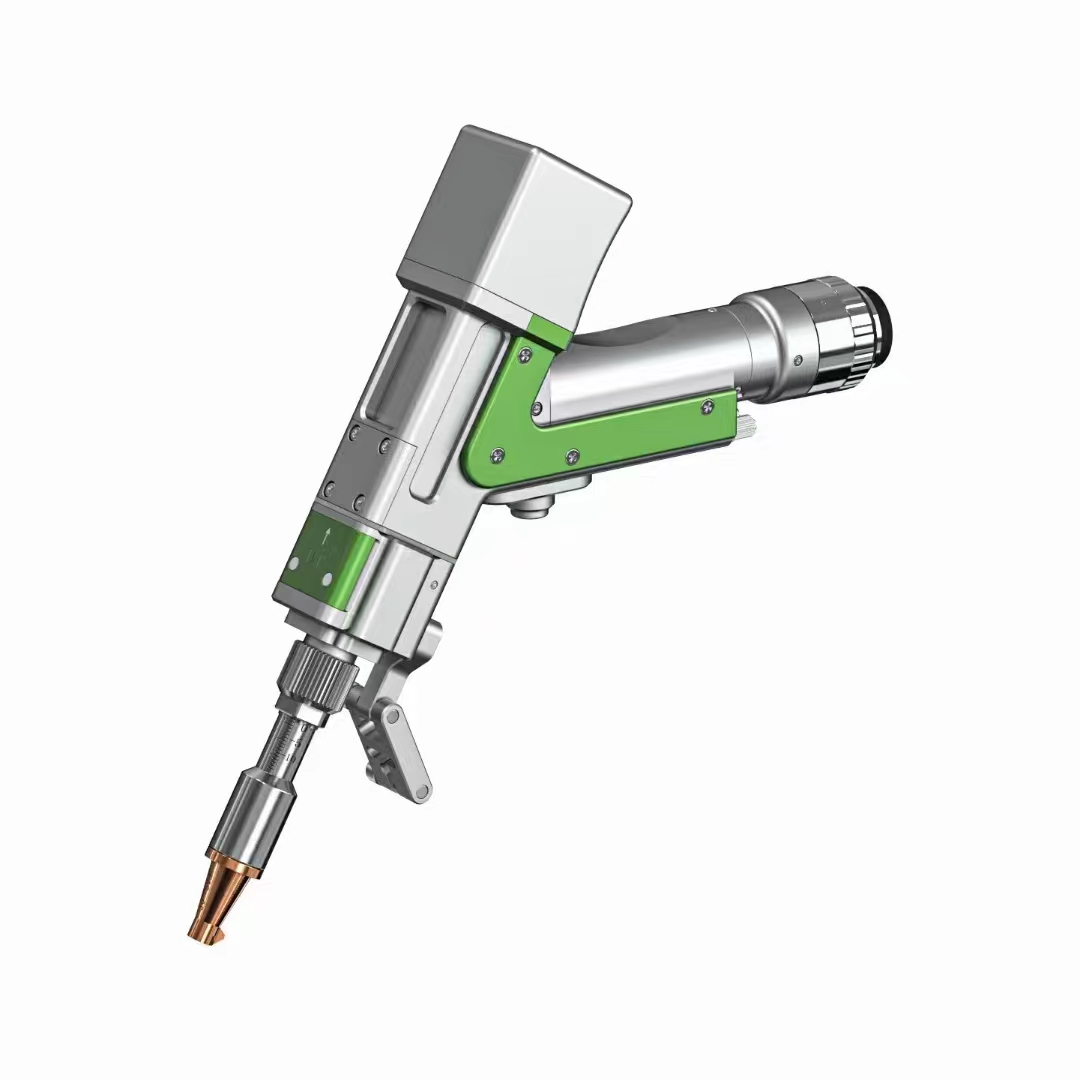

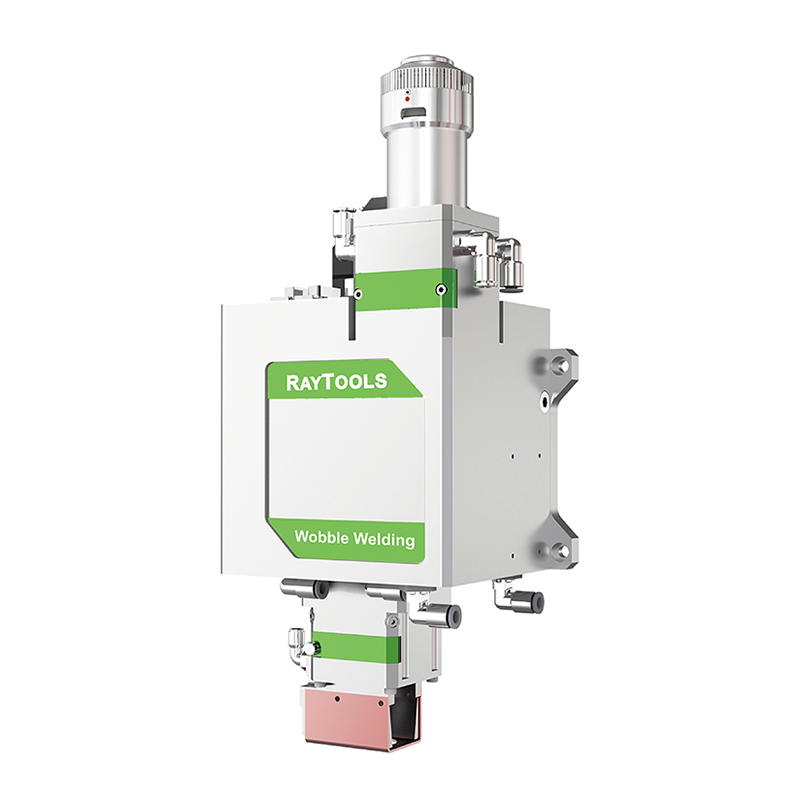

About Fortune Laser RelFar 3 In 1 Laser Head Features

1. Lightweight design, light and easy to operate, the handheld head is only 710g, lighter than other handheld heads;

2. Remote worry-free, mobile terminal Bluetooth; match and connect with the mobile terminal through Bluetooth for remote operation;

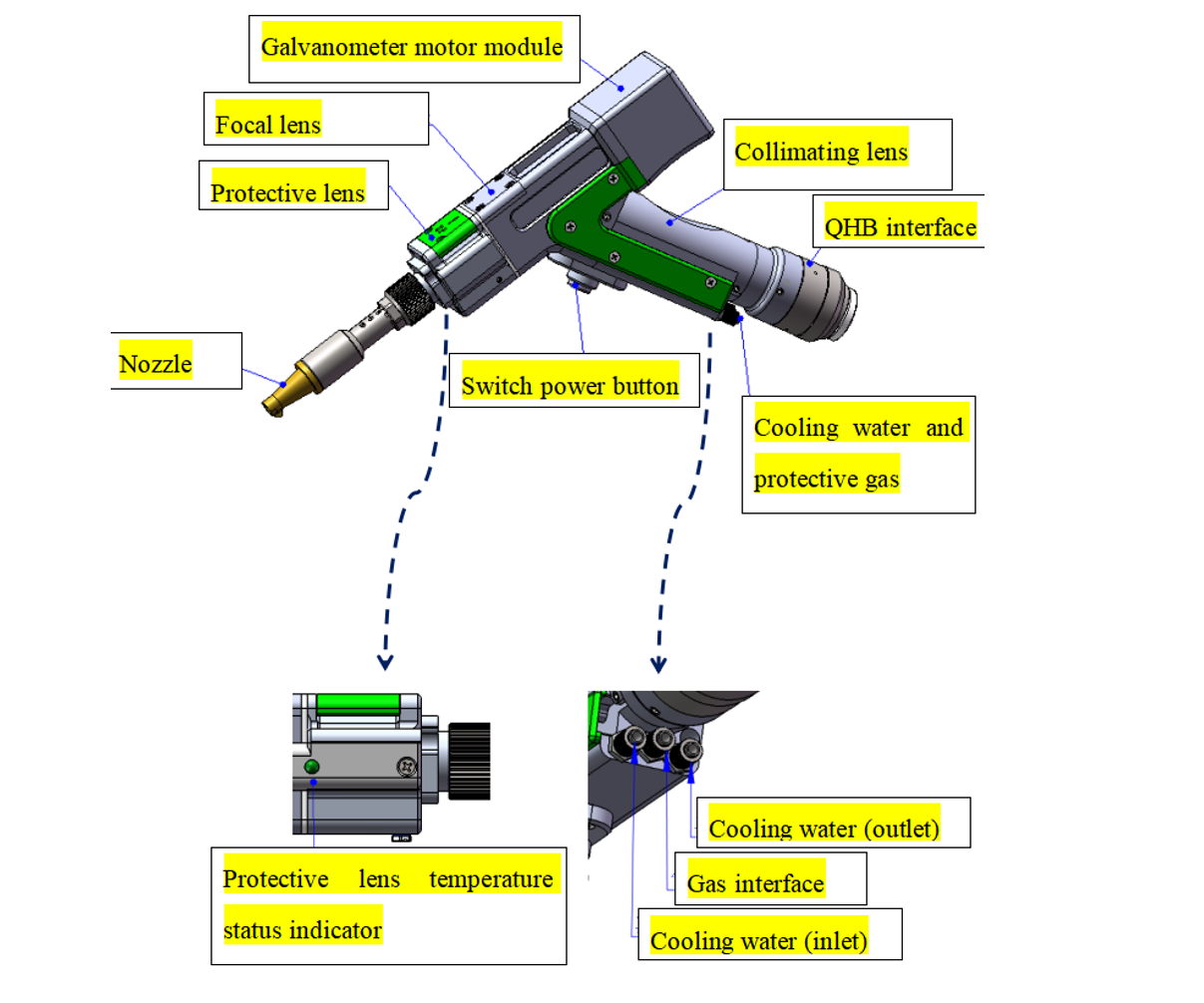

3. Temperature control display, with protective lens temperature, status display light visual display

4. Multiple security locks

Laser head details

1) Structure of product

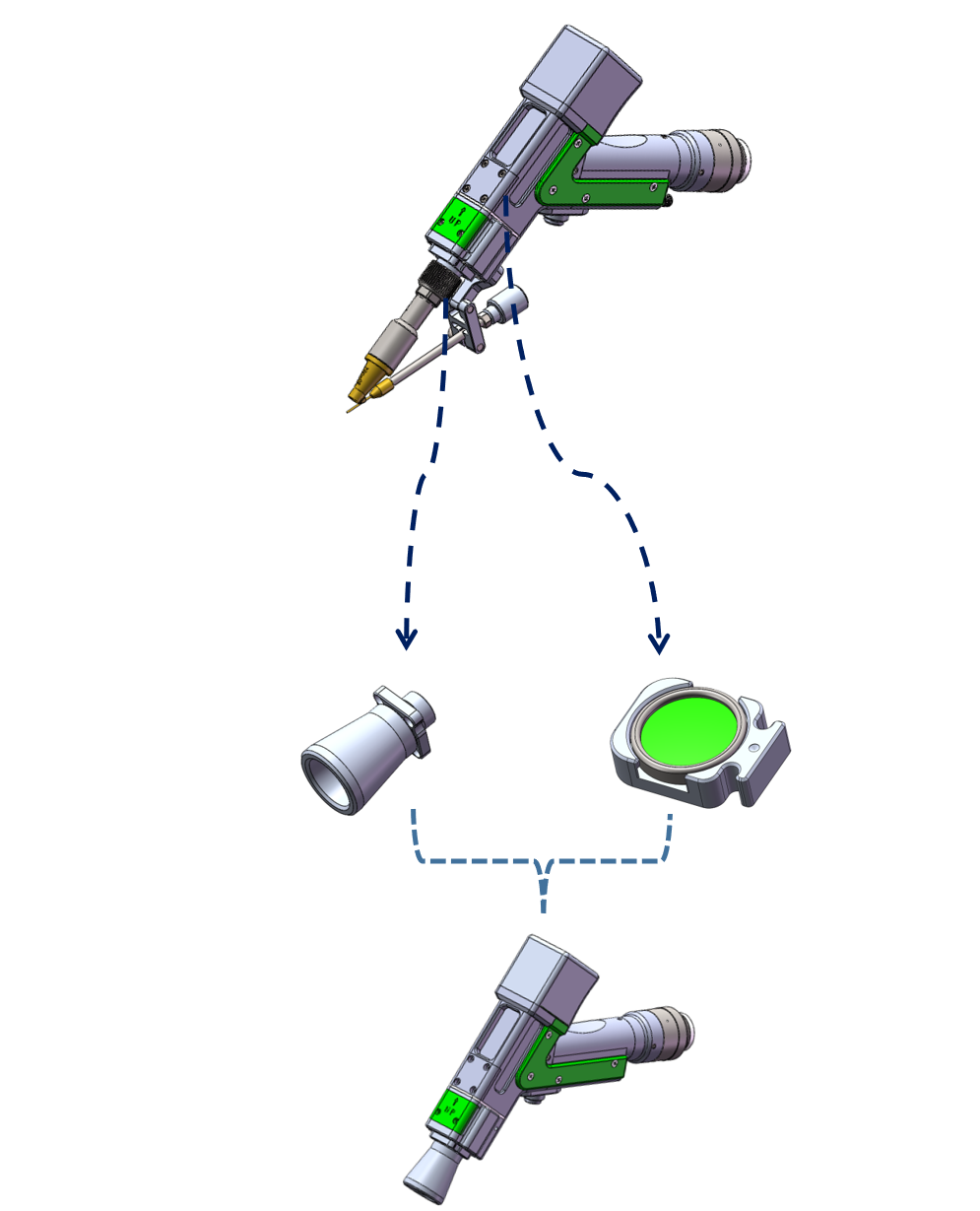

2) The schematic diagram of structural part replacement is as follows

Laser head parameter

|

Supply voltage (V) |

220V±10% AC 50/60Hz |

|

Rated power |

≤3000W |

|

Collocated focal length |

50mm |

|

Optical Fiber Interface |

QBH |

|

Focus/Clean Focal Length |

F150mm |

|

Swing range |

0.1-5mm |

|

Cooling method |

Water chiller |

|

Facula Adjustment Range |

0~5mm |

|

Weight |

0.71kg |

|

Optional |

Cleaning Head / Wire Feeder / Cutting Tip / Welding Kit |

|

Focus vertical adjustment range |

±10mm |

Wire Feeder Details

1. Functional application, wire feeding.

2. High-power motor, fast and accurate wire feeding, improving welding efficiency.

3. Double drive wire feeding, large thrust, more stable wire feeding.

4. With brake resistance disk shaft, to prevent the welding wire from loosening when the motor stops.

5. The fuselage comes with sliding wheels, which is easy to move.

6. The wire storage capacity is large, ready to go.

|

Wire weight |

Up to 25kg |

|

Wire core diameter |

3.0mm |

|

Wire feeding speed |

80mm/s |

|

Motor type |

57 stepper motor |

|

Reduction ratio |

1:5 |

|

Weight |

16.2kg |

|

Power |

220V |

|

Size |

56*24*47cm |

Part of the Introduction for reference.

7.2 Introduction to HMI operations

7.2.1 Parameter setting:

The parameter setting includes: The setting of homepage, system parameters, wire feeding parameters and diagnosis.

Homepage: It is used to set parameters related to laser, wobbling and process library during welding.

Process library: Click the area of the white box of process library to choose the set parameters of process library.

Welding mode: Set welding mode: continuous, pulse mode.

Laser power: Set the peak power of laser during welding.

Laser frequency: Set the frequency of laser PWM modulation signal.

Duty Ratio: Set the duty ratio of PWM modulation signal, and the setting range is 1% – 100%.

Wobbling frequency: Set the frequency at which the motor swings the wobble.

Wobbling length: Set the width of the motor swing wobble.

Wire feeding speed: Set the speed of wire feeding during welding.

Time of laser-on: Laser-on time in spot welding mode.

Spot welding mode: Click to enter the mode of laser-on during spot welding.

7.2.2【System parameters】: It is used to set the basic parameters of the equipment. It is generally configured by the manufacturer. You need to enter a password before entering the page.

The system access password is: 666888 six digits.

Pulse on time: The laser-on time under the pulse mode.

Pulse off time: The laser-off time under the pulse mode.

Ramp time: It is used to set the time when the laser analog voltage slowly increases from the initial power to the maximum power at startup.

Slow descent time: It is used to set the time when the laser analog voltage changes from the maximum power to the laser-off power when it stops.

Laser-on power: It is used to set the laser-on power as the percentage of welding power.

Laser-on progressive time: Control the time for the laser-on to rise slowly to the set power.

Laser-off power: It is used to set the laser-off power as the percentage of welding power.

Laser-off progressive time: Control the time taken by slowly laser-off.

Language: It is used for the language exchange.

Early air opening delay: When starting processing, you can set the delayed gas on. When you press the external startup button, blow the air for a period of time and then start the laser.

Late air opening delay: When stopping processing, you can set a delay to turn off the gas. When processing is stopped, stop the laser first, and then stop blowing after a period of time.

Automatic wobble: It is used to automatically wobble when setting the galvanometer; enable the automatic wobble. When the safety lock is turned on, the galvanometer will automatically wobble; when the safety lock is not turned on, the galvanometer motor will automatically stop wobbling after a time delay.

Device parameters: It is used to switch to the device parameters page, and a password is required.

Authorization: It is used for authorization management of mainboard.

Device number: It is used to set the Bluetooth number of the control system. When users have multiple devices, they can freely define numbers for management.

Center offset: It is used to set the center offset of red light.

7.2.3【Wire feeding parameters】: It is used to set wire feeding parameters, including wire filling parameters, wire back offing parameters, etc.

Back offing speed: The speed of the motor to back off the wire after releasing the start switch.

Wire back offing time: The time of the motor to back off the wire.

Wire filling speed: The speed of the motor to fill the wire.

Wire filling time: The time of the motor to fill the wire.

Wire feeding delay time: Delay the wire feeding for a period of time after the laser-on, which is generally 0.

Continuous wire feeding: It is used for the wire replacement of wire feeding machine; the wire would be fed continuously with one click; and then it would stop after another click.

Continuous wire back offing: It is used for the wire replacement of wire feeding machine; the wire could be back offed continuously with one click; and then it would stop after another click.

Please feel free to contact us for more details!

Product detail pictures:

Related Product Guide:

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for 100% Original Robotic Laser Welding Machine - Fortune Laser Hot Sale 1000W-3000W 3 In 1 Laser Systsem Handheld Laser Welding Cleaning Cutting Machine – Fortune , The product will supply to all over the world, such as: US, Honduras, Panama, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.